Clothes dryer and drying method thereof

A technology for clothes dryers and drying cylinders, applied in the field of washing machines, which can solve the problems of less shortened time, less obvious effects, and low drying efficiency, and achieve the effects of saving heating time, reducing energy consumption, and preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

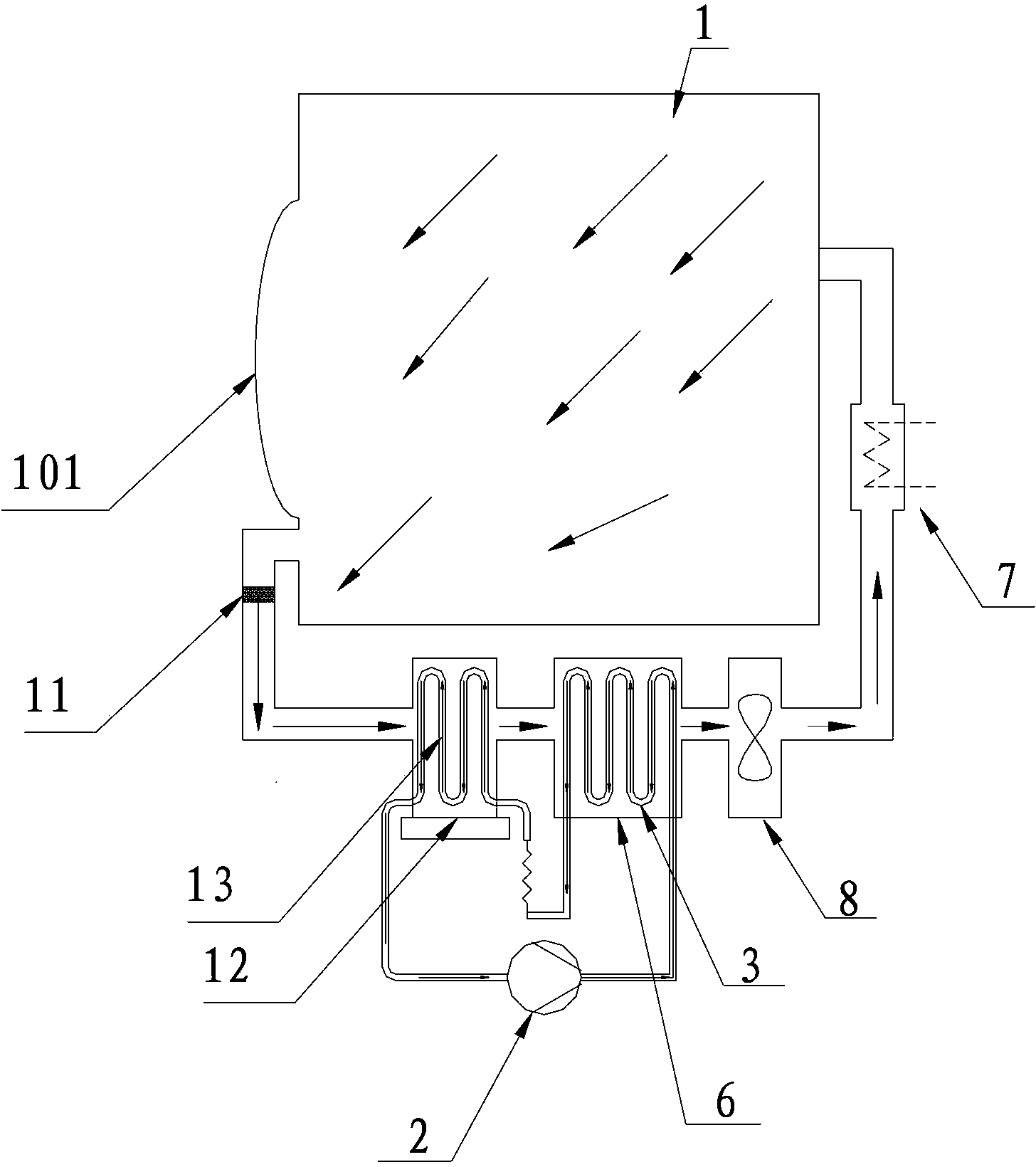

[0047] An embodiment of the present invention provides a clothes dryer, figure 2 is a structural diagram according to an embodiment of the present invention,

[0048] Such as figure 2 As shown, this embodiment includes: a drying cylinder 1 , an air compressor 2 , a condenser 3 , a water vapor separator and a drainage device 4 , and a heating wire 7 .

[0049] The exhaust end of the drying cylinder 1 described in this embodiment is connected to the intake end of the air compressor 2, and the exhaust end of the air compressor 2 is connected to the intake end of the condenser 3, The exhaust end of condenser 3 is connected with the inlet end of water-gas separator and drainage device 4, the inlet end of preheating pipe 6 is connected with the exhaust end of water-gas separator and drain device 4 through pipelines, The exhaust end of the preheating pipe 6 is connected with the inlet end of the drying cylinder 1 through a heating wire 7 . The condenser 3 is arranged in the preh...

specific Embodiment 2

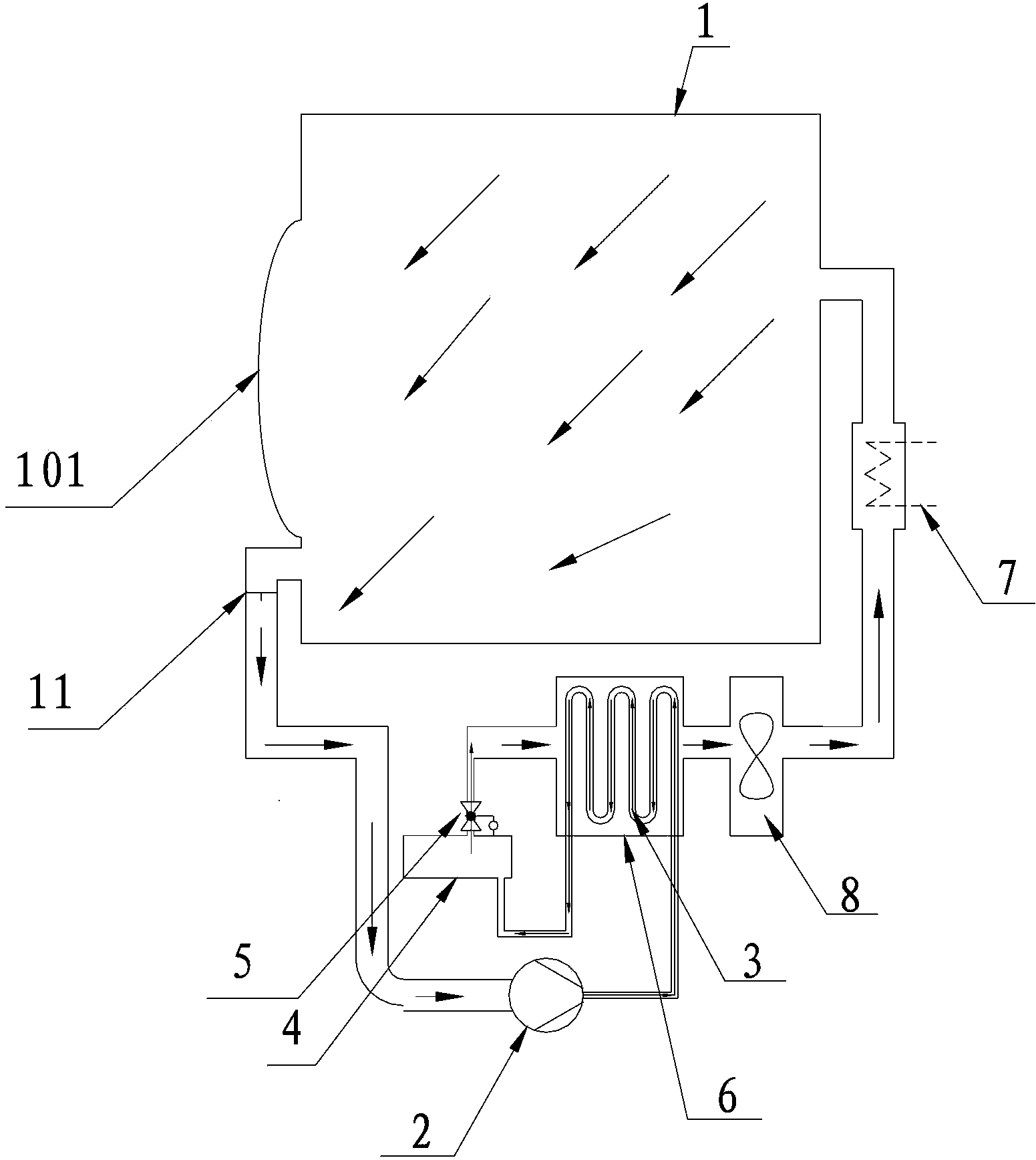

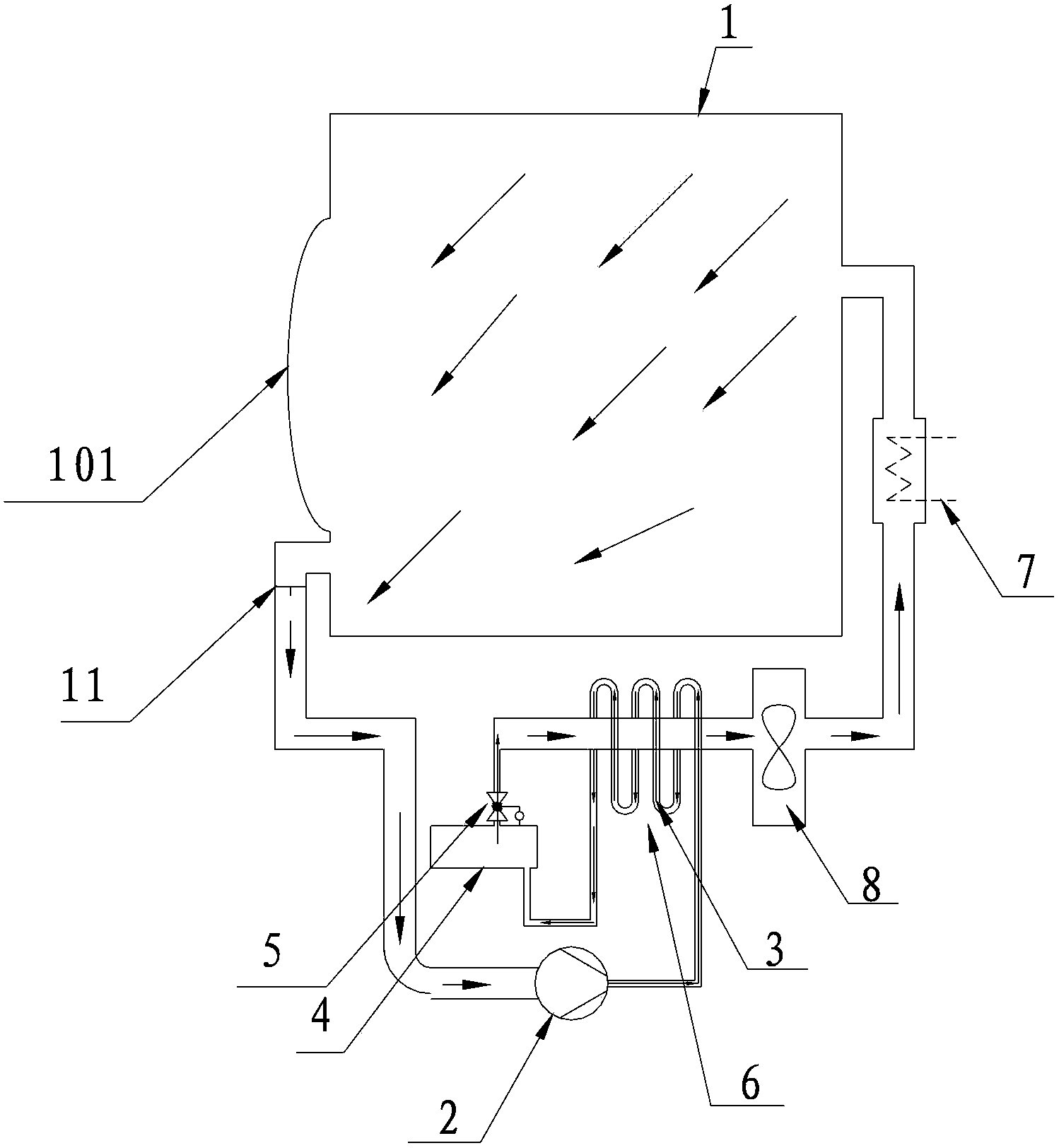

[0058] see Image 6 with Figure 7 As shown, this embodiment includes: a drying cylinder 1 , a condenser 3 , an air compressor 2 , a water vapor separator and a drainage device 4 , and a heating wire 7 .

[0059] The exhaust end of the drying cylinder 1 described in this embodiment is respectively connected to the air compressor 2 and the inlet end of the pipe to be heated 6 through the air passage valve 9, and the air passage valve 9 is connected to the control device 10, The exhaust end of the air compressor 2 is connected with the intake end of the condenser 3, and the exhaust end of the condenser 3 is connected with the intake end of the water-gas separator and the drainage device 4, and the preheating pipe 6 The inlet end of the air inlet is connected with the exhaust end of the water-gas separator and the drainage device 4 through a pipeline, and the exhaust end of the preheating pipe 6 is connected with the inlet end of the drying cylinder 1 through the heating wire 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com