Shield tunneling machine shield tail synchronous embedded-type double-liquid grouting device

A dual-liquid grouting, embedded technology, applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve the problems of poor use effect, blockage of liquid pipes, complicated operation, etc., achieve simple structure, prevent water seepage, easy to use effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

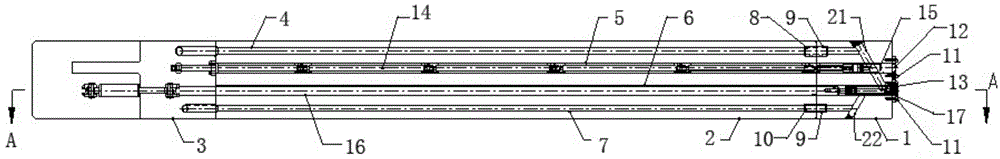

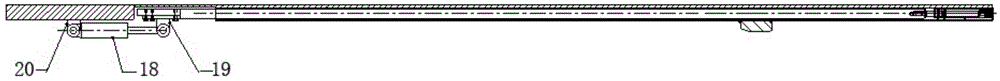

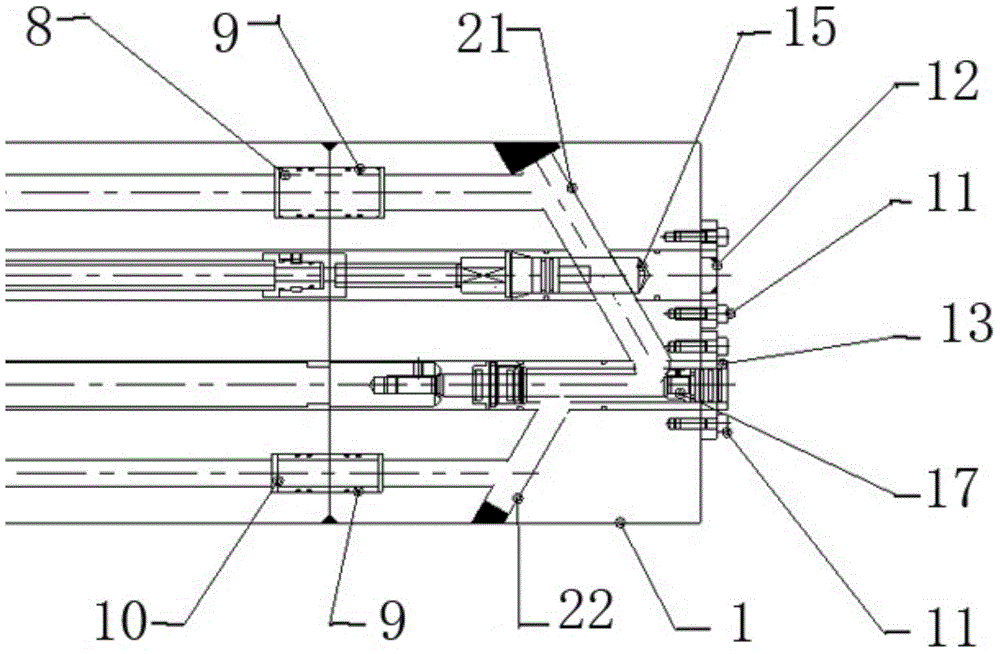

[0015] Such as Figure 1 to Figure 3 As shown, the present invention includes a first valve block 1, a second valve block 2 and a shield connecting block 3, the first valve block 1 is welded to the second valve block 2, the second valve block 2 is welded to the shield connecting block 3, Corresponding A liquid channel 4, B liquid channel 5, piston channel 6 and water channel 7 are arranged in the first valve block 1 and the second valve block 2, and correspondingly arranged in the first valve block 1 and the second valve block 2 A liquid channel 4 is connected at the connection between the first valve block 1 and the second valve block 2 through the A liquid seam pipe 8 and the sealing ring 9; the water channel 7 correspondingly arranged in the first valve block 1 and the second valve block 2 is in The connection between the first valve block 1 and the second valve block 2 is connected through a water joint pipe 10 and a sealing ring 9 . The end of the first valve block 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com