Vibration targeting control device for multi-span rotor shaft of rotary machine

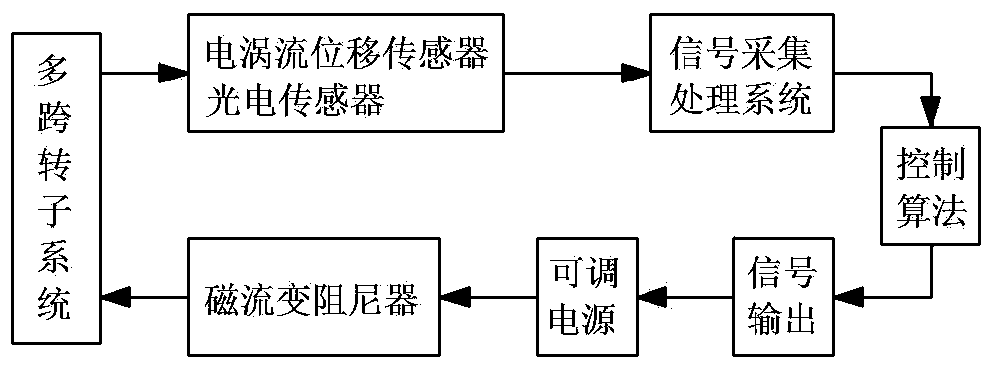

A technology for rotating machinery and control devices, which is applied in the directions of rotational vibration suppression, non-rotational vibration suppression, and vibration suppression adjustment, which can solve problems such as inability to start and stop normally, and achieve the effect of solving rotor rubbing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

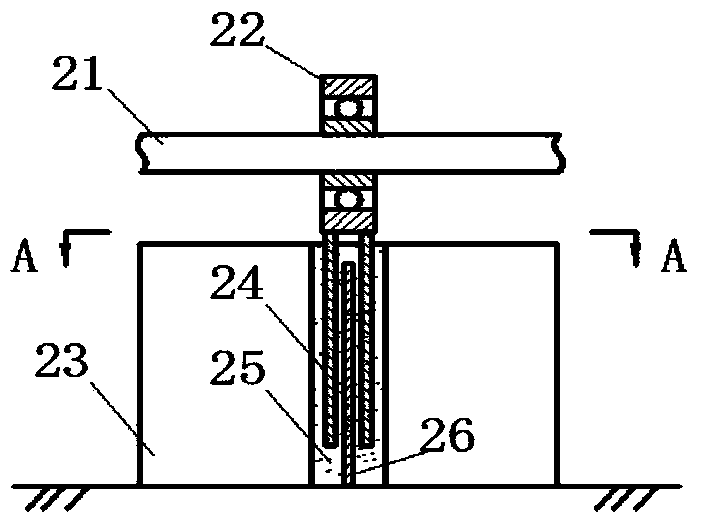

Examples

Embodiment 1

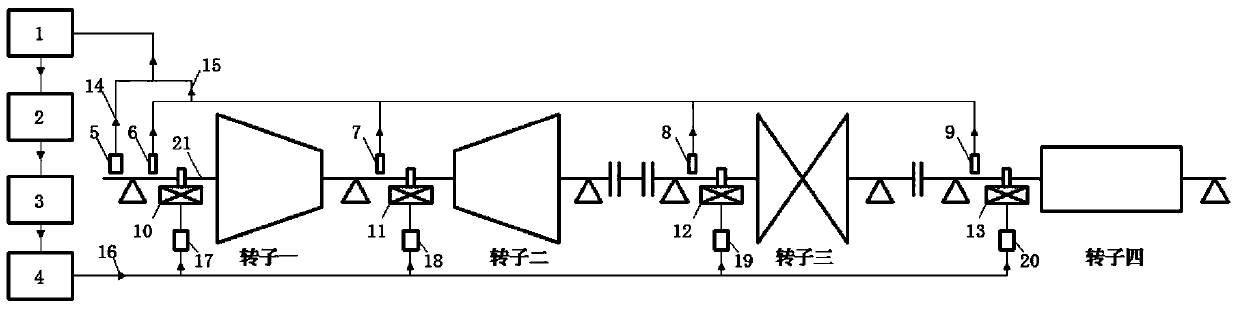

[0045] by figure 2Taking the shafting of the medium generator set as an example, the specific control scheme during the starting process of the shafting is shown in Table 2; the speed increases gradually from 0r / min, and all the magneto-rheological dampers are closed at this time. When the speed reaches about 850r / min min, the control signal 16 controls the adjustable power supply D20 to turn on the magneto-rheological damper D13; when the speed reaches about 1150r / min, the control signal 16 controls the adjustable power supply 20 to turn off the magneto-rheological damper D13; when the speed reaches about At 1275r / min, the control signal 16 controls the adjustable power supply B18 to turn on the magneto-rheological damper B11; when the speed reaches about 1658r / min, the control signal 16 controls the adjustable power supply A17 to turn on the magneto-rheological damper A10; When the speed reaches about 1725r / min, the control signal 16 controls the adjustable power supply B18...

Embodiment 2

[0051] by figure 2 Taking the mid-span rotor shaft system as an example, the specific control scheme during the shaft shutdown process is shown in Table 2. The speed gradually decelerates from 3000r / min, and the adjustable power supply D20 is controlled to turn on the magneto-rheological damper D13, and the other dampers are turned off; when the speed reaches about 2358r / min, the adjustable power supply C19 is controlled to turn on the magneto-rheological damper C12; When the rotating speed reaches about 2253r / min, control the adjustable power supply D20 to close the magnetorheological damper D13; when the rotating speed reaches about 2243r / min, control the adjustable power supply A17 to turn on the magnetorheological damper A10; when the rotating speed reaches about At 1743r / min, control the adjustable power supply C19 to turn off the magnetorheological damper C12; when the speed reaches about 1725r / min, control the adjustable power supply B18 to turn on the magnetorheologic...

Embodiment 3

[0055] by figure 2 Take the mid-span rotor shafting system as an example. When the shafting system runs on a certain span or several spans of the rotor due to blade breakage, dust accumulation, etc. due to unbalanced faults, the time domain, frequency domain and axis trajectory of the rotor vibration It has certain characteristics; the real-time online signal monitoring and analysis system in the present invention will make judgments based on these characteristics, determine the position of the rotor where the unbalanced fault occurs, and control the opening of the magneto-rheological damper on the corresponding rotor, and give an appropriate working current. Assuming that the rotor 1 of the shaft system vibrates violently due to rotor wear during operation, the real-time online signal monitoring and analysis system determines that the rotor with severe vibration is rotor 1 based on the collected vibration data across the rotors. After system analysis and calculation, the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com