LED lamp tube and manufacturing method thereof

A technology for an LED lamp tube and a manufacturing method, which is applied to the field of the LED lamp tube and its manufacturing, can solve the problems of affecting the lighting effect, waste of energy, and low luminous flux of the plastic lamp tube, so as to improve the lighting effect, improve the utilization rate, improve the light not dazzling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

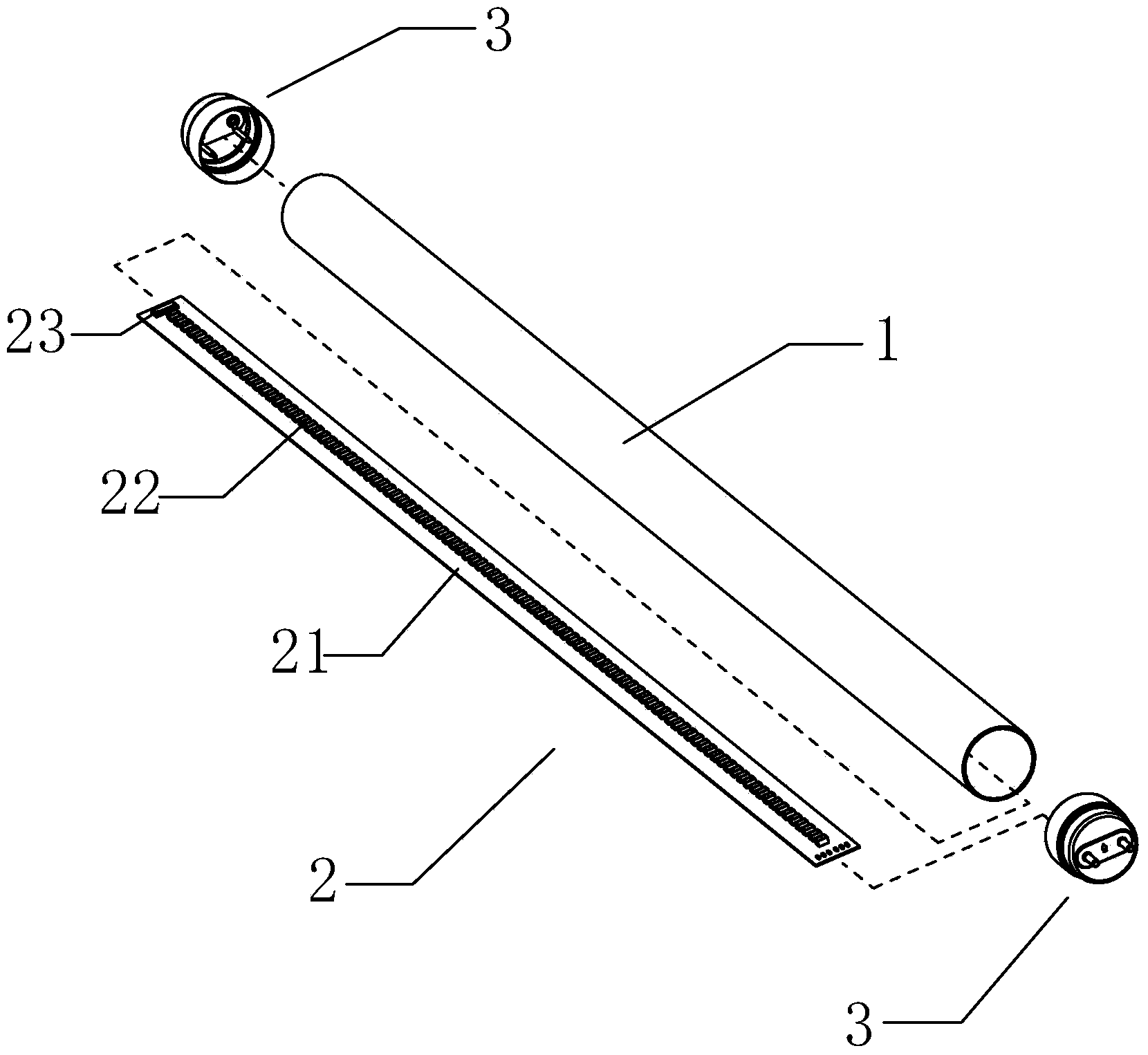

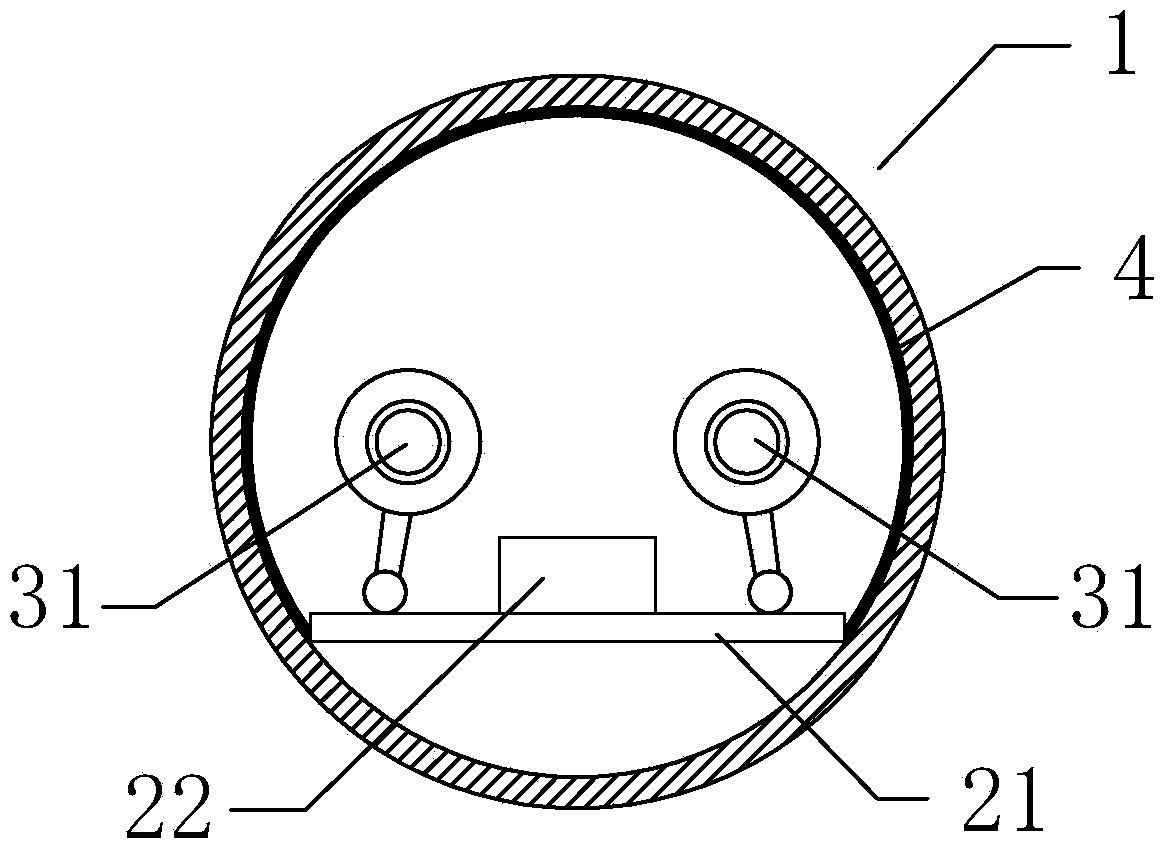

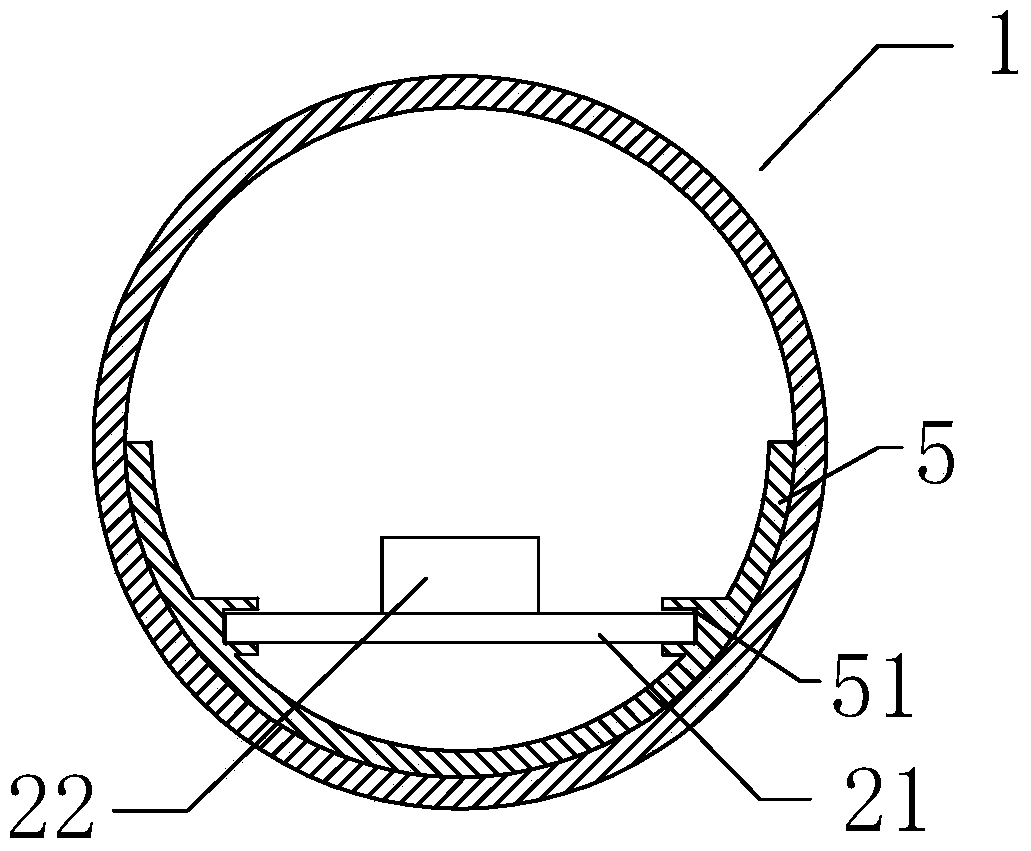

[0026] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of a specific embodiment of the LED lamp tube of the present invention. As shown in the figure, an LED lamp tube includes a lamp tube body 1, an LED light source assembly 2 arranged in the lamp tube body 1, and a lamp The lamp foot group 3 on the tube body 1 and connected to the LED light source assembly 2, the LED light source assembly 2 includes a PCB board 21, a power supply assembly 23 arranged on the PCB board 21 and several LED chips arranged on the PCB board 21 22. The PCB board 21 can be a fiberboard or a flexible lamp board, etc., and the lamp pin group 3 is provided with pins 31, and the pins 31 are electrically connected to the power supply assembly 23 on the PCB board 21, and the lamp tube The body 1 is integrally formed of glass material, and the inner wall of the lamp body 1 is provided with a diffusion coating 4 .

[0027] In this embodiment, after the PCB board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com