Heat exchanger operation auxiliary system and heat exchanger system using the system

An auxiliary system and heat exchanger technology, applied in the direction of adsorption machines, lighting and heating equipment, climate change adaptation, etc., can solve the problems of blocking air circulation, affecting the normal operation of air conditioners, and poor comfort, so as to improve heat exchange performance, Good energy-saving effect and the effect of improving the condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

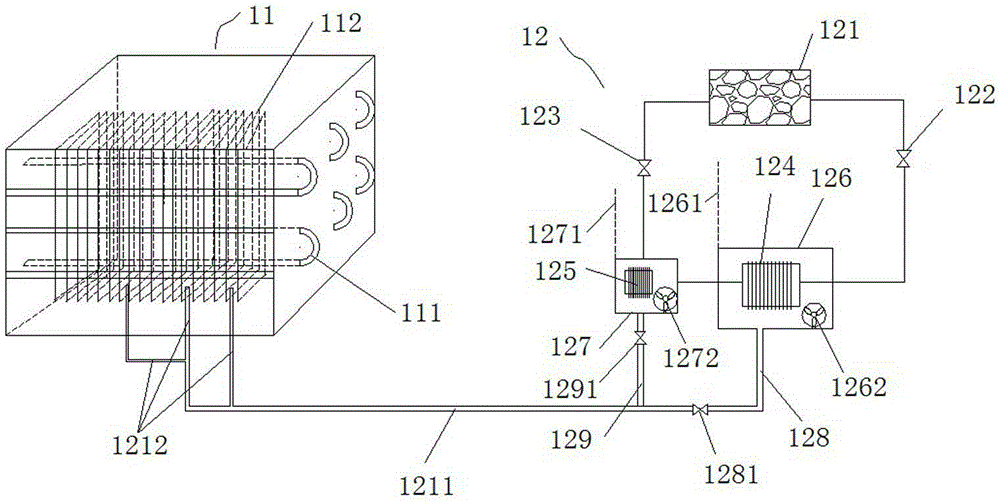

[0018] Embodiments of the heat exchanger system in the present invention are as figure 1 As shown, it includes a heat exchanger 11 and a heat exchanger operation auxiliary system 12. The heat exchanger 11 includes a heat exchange tube 111 and a heat exchanger fin 112 for enhancing the heat exchange efficiency of the heat exchange tube 111; The auxiliary system 12 includes a solid adsorption refrigeration system and corresponding heat transfer device and cold transfer device. The heat transfer device is used to evaporate the high-temperature medium around the refrigeration system condenser 124 of the heat exchanger operation auxiliary system 12 to the heat exchanger system The cold delivery device is used to transport the low-temperature medium around the evaporator 125 of the refrigeration system of the heat exchanger operation auxiliary system 12 to the condenser of the heat exchanger system.

[0019] The solid adsorption refrigeration system is an existing technology, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com