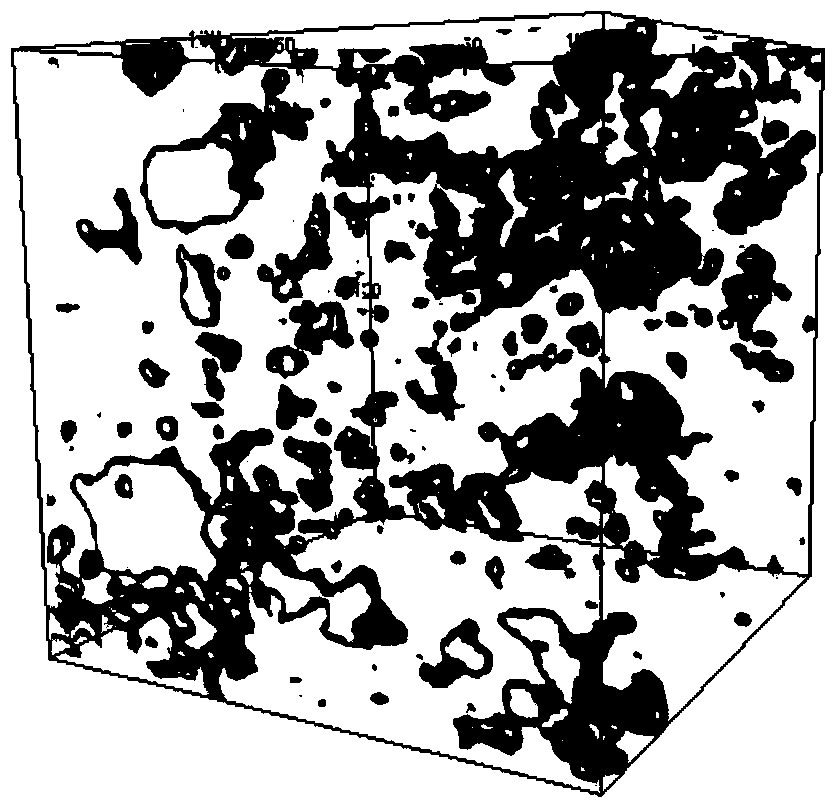

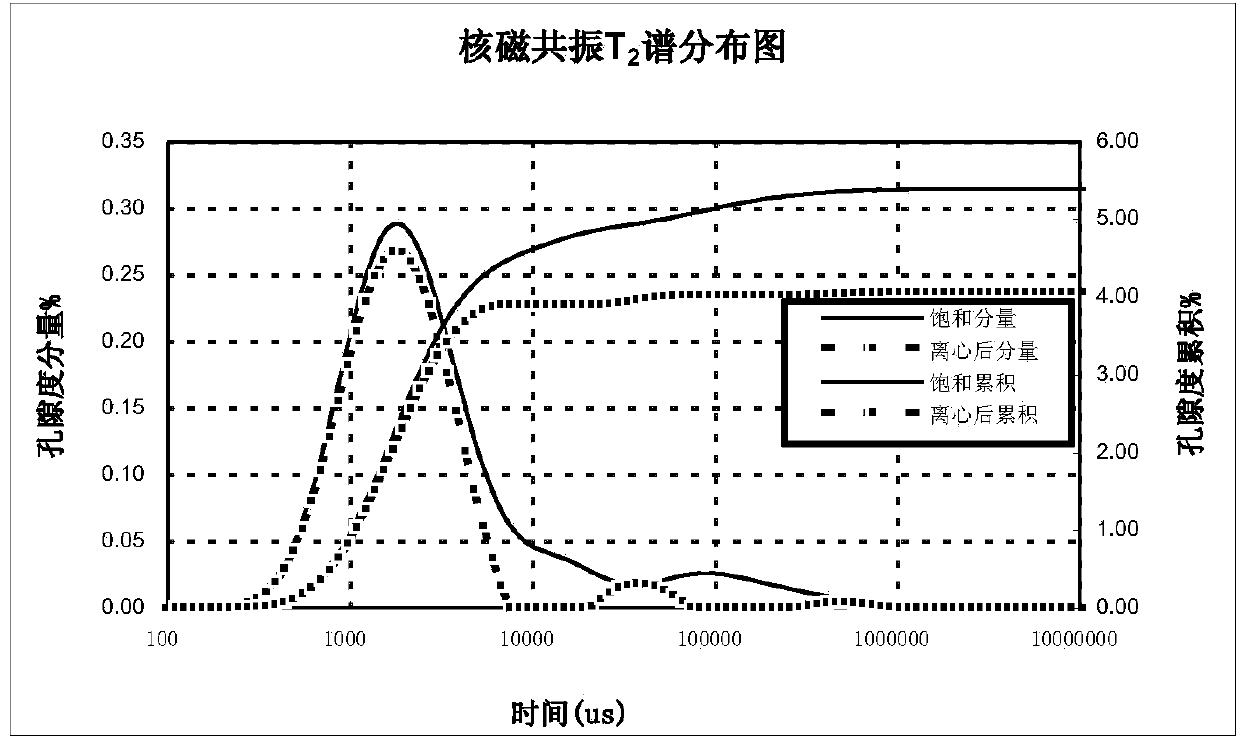

High-resolution three-dimensional digital rock core modeling method

A three-dimensional digital, high-resolution technology, applied in the analysis of materials, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of low porosity of digital core, unfavorable numerical simulation research, and influence of digital core pore connectivity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below with reference to the accompanying drawings and examples. The source of the project to which this example belongs is the National Major Science and Technology Special Project "Research on Key Technologies of Fine Exploration and System Supporting Research", and the project number is funded by 2011ZX05006-002.

[0057] Specific steps are as follows:

[0058] Step 1: Scan the core with X-ray CT.

[0059] The X-ray CT scanning instrument used in the study is SkyScan1174 with a resolution of 6.5um.

[0060] When X-rays penetrate an object, complex physical processes such as photoelectric effect, Compton effect, electron pair effect and Rayleigh scattering will occur, and the ray intensity will attenuate due to reflection, scattering and absorption. Different material compositions have different absorption coefficients for X-rays. Generally speaking, how much a sample absorbs X-rays depends on the density of each compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com