Principal component regression analysis method of non-oriented silicon steel magnetism performance influence factor

A principal component regression, oriented silicon steel technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of rare and difficult to determine magnetic properties and other factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

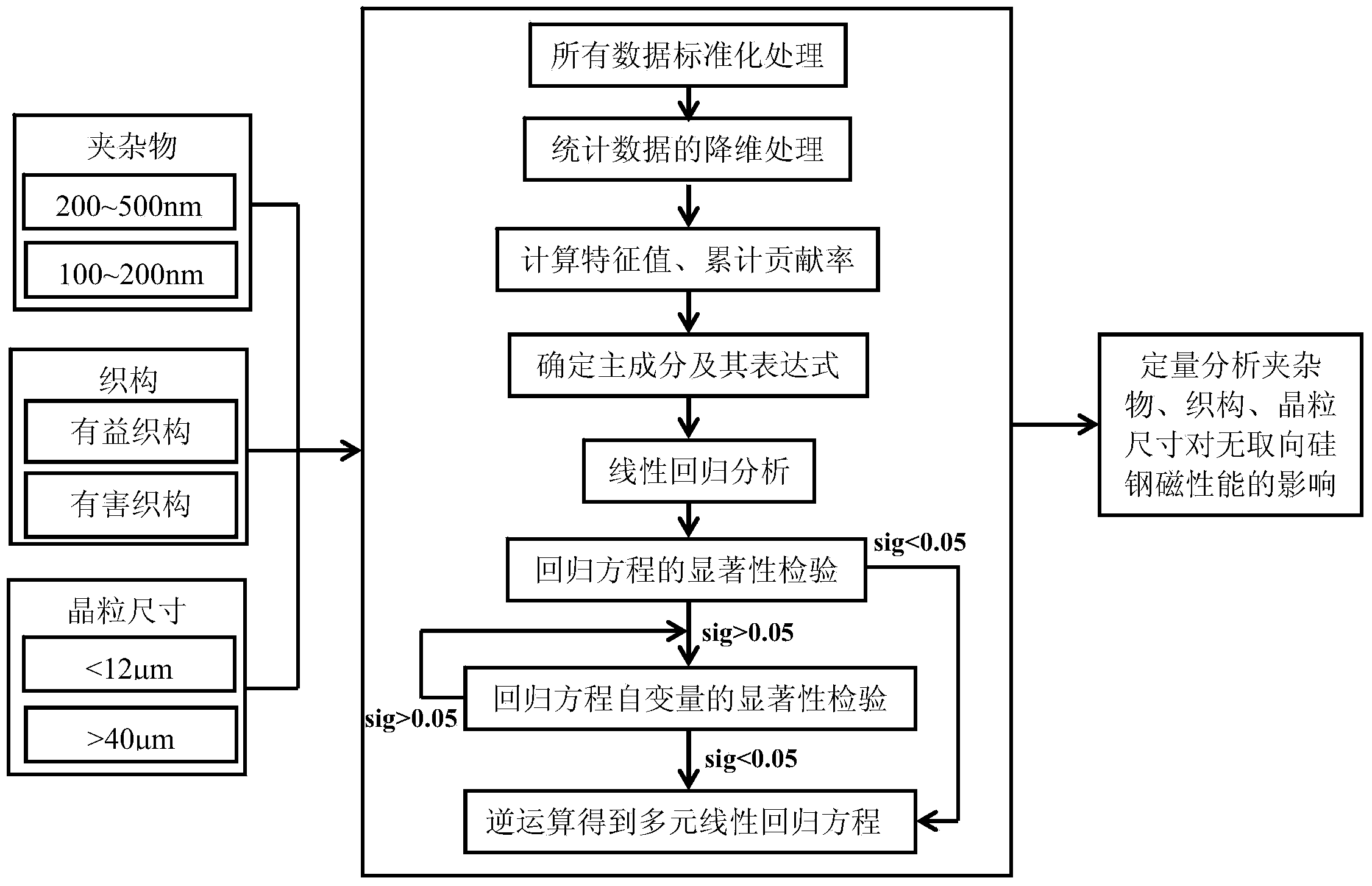

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further explained and illustrated below in conjunction with the embodiments and accompanying drawings.

[0043] The embodiment adopts the non-oriented silicon steel 50SW1300 finished product test sample provided by a steel factory after continuous casting, hot rolling (2.6mm thick), cold rolling (0.5mm thick), continuous annealing and surface coating, and selects 10 sets of magnetic properties Various samples were studied, and the magnetic properties of each group of samples are shown in Table 2.

[0044] The magnetic property of table 2 embodiment sample

[0045]

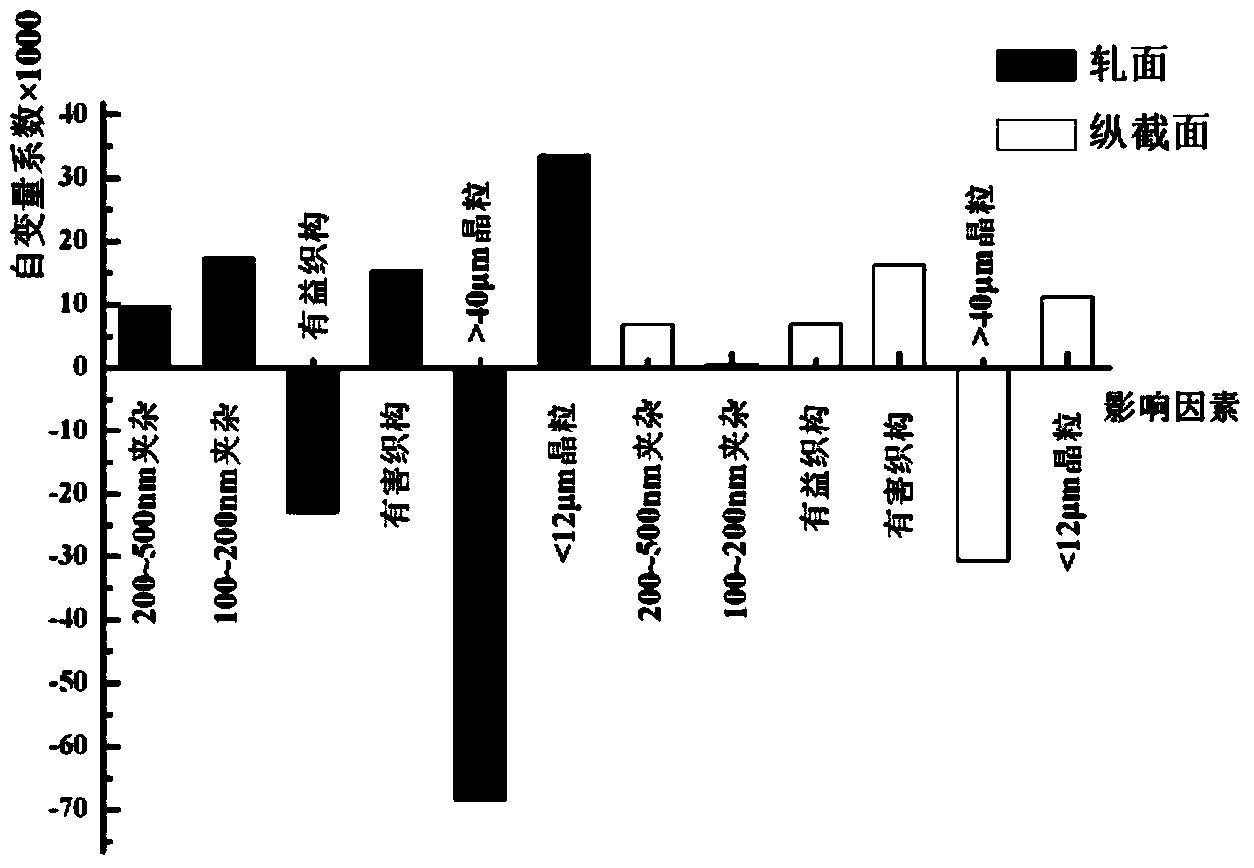

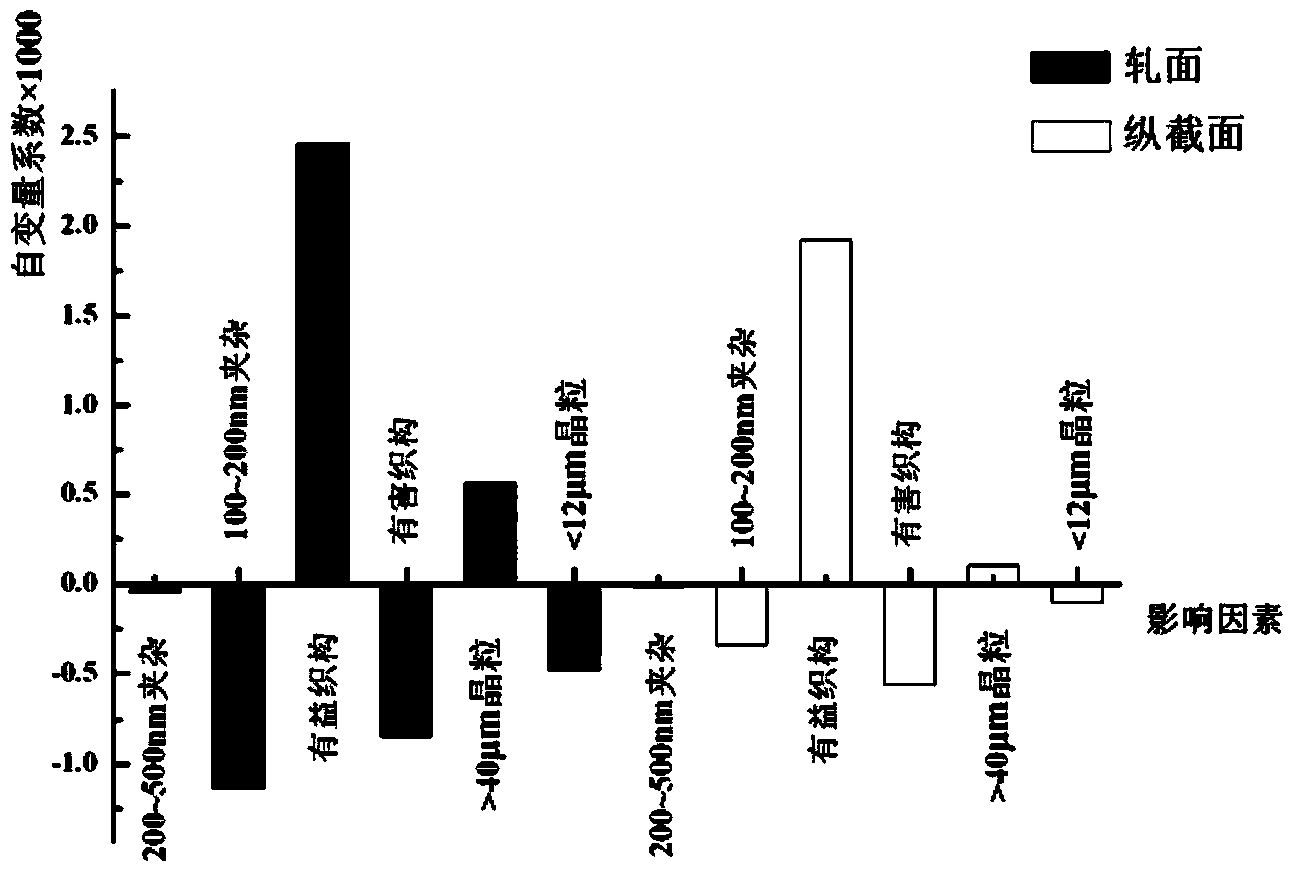

[0046] Use ZEISS ULTRA55 field emission scanning electron microscope and energy spectrometer to conduct random continuous observation of inclusions under the field of view of 5000-20000 times, and the statistical points are >1000nm, 500-1000nm, 200-500nm, 100-200nm four size ranges, mainly Study the inclusion content in the size range of 200-500nm and 100-200nm.

[0047] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com