Flame-retardant resin composition and melt-molded body

A resin composition and flame retardant technology are applied in the field of resin compositions to achieve the effects of flame retardancy, transparency, and excellent aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] In order to further describe the present invention in detail, the following examples and comparative examples are given, but the present invention is not limited to the examples. In addition, "part" and "%" in each example are based on weight. In addition, each evaluation value is the numerical value measured by the following method.

[0053]

[0054] (1) Phosphorus concentration: measured by atomic absorption photometry. The unit is mg / kg.

[0055] (2) Transparency: A 10 cm square flat plate with a thickness of 2 mm was produced by injection molding, and the haze was measured with a haze meter (manufactured by Nippon Denshoku Industries Co., Ltd., MODEL NDH2000). In addition, samples with a haze exceeding 10% were judged as "opaque".

[0056] (3) Flame retardancy

[0057] Test method: according to UL-94 (average fire extinguishing time of 5 samples)

[0058] Test piece thickness: 1.6mm, 3.2mm

[0059] Evaluation: V-0, V-1, V-2 in the specified order

[0060] (...

Embodiment 1

[0064] To the thermoplastic resin (A), 80 parts by weight of polycarbonate resin (manufactured by Mitsubishi Engineering Plastics Corporation, trade name: Upiron H-3000), phosphorus-containing copolyester resin (B) (manufactured by Toyobo Co., Ltd., trade name Name: Bilon GH-230, phosphorus concentration 30000 mg / kg, limiting viscosity 0.66 dL / g) 10 parts by weight, phosphorus-containing compound (C) (manufactured by Sanko Co., Ltd., trade name: BCA, phosphorus concentration 101000 mg / kg) 10 parts by weight The mixture was mixed in a Henschel mixer, and melt-kneaded in a vented twin-screw extruder to obtain pellets of the resin composition 1. The obtained pellets were molded with an injection molding machine, and a test piece for a flame retardancy test (thickness 1.6 mm, 3.2 mm) and a 10 cm square flat plate with a thickness of 2 mm were produced, and physical properties were measured according to the above analysis and evaluation methods.

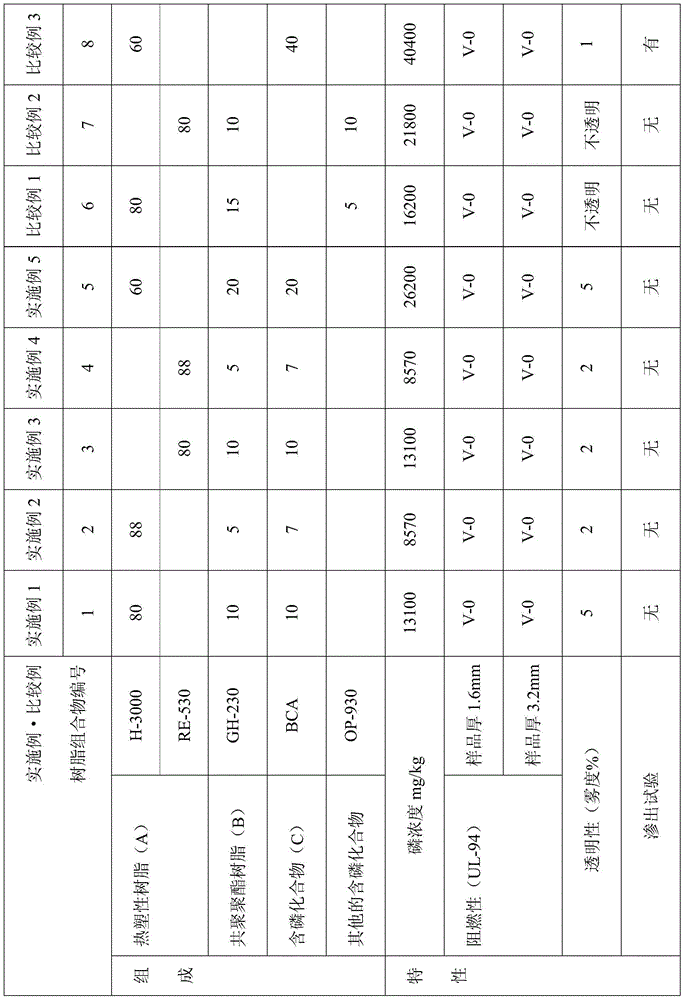

Embodiment 2~5, comparative example 1~3

[0066] The same operation as in Example 1 was performed, but the compounding ratio was changed as shown in Table 1, resin compositions 2 to 8 were produced, and it was evaluated in the same manner as in Example 1. The evaluation results are shown in Table 1.

[0067] [Table 1]

[0068]

[0069] H-3000: Polycarbonate resin, manufactured by Mitsubishi Engineering-Plastics Corporation, brand name: Yupiron H-3000

[0070] RE-530: Polyethylene terephthalate resin, manufactured by Toyobo Co., Ltd., trade name: RE-530, limiting viscosity 0.53dL / g

[0071] GH-230: Copolyester resin (B) obtained by copolymerizing the phosphorus-containing component represented by the general formula (1), manufactured by Toyobo Co., Ltd., trade name: Bilon GH-230, phosphorus concentration 30000 mg / kg, intrinsic viscosity 0.66 dL / g

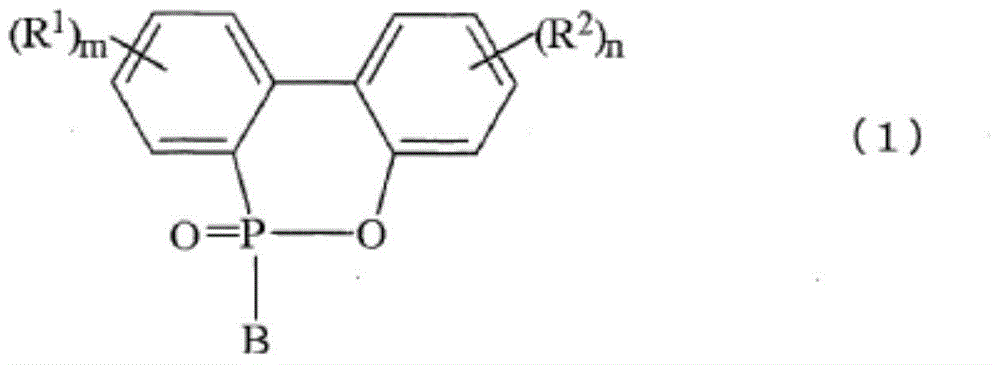

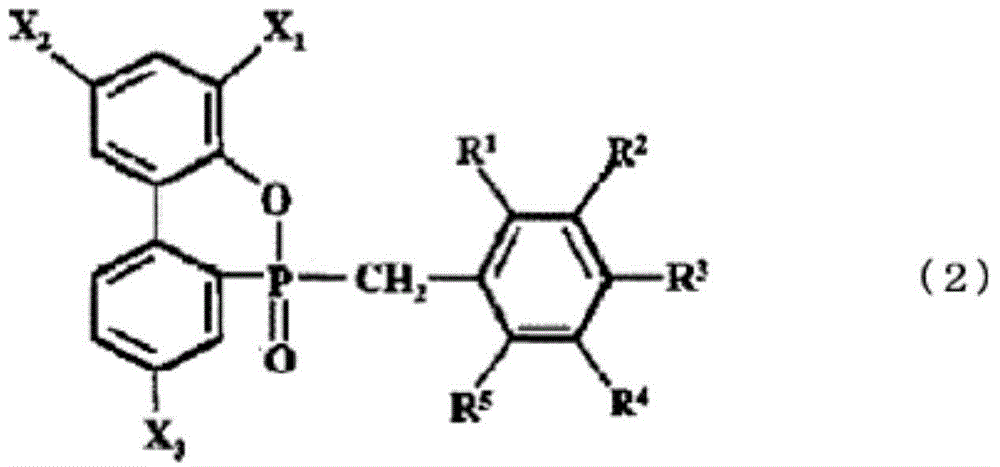

[0072] BCA: a phosphorus-containing compound (C) represented by the general formula (2), manufactured by Sanko Co., Ltd., trade name: BCA, and a phosphorus concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com