Adhesive tape for non-aqueous battery

A non-aqueous battery and adhesive tape technology, applied in the field of adhesive tape, can solve the problems of electrolyte deterioration of battery characteristics, easy contact with electrolyte, easy deformation of adhesive layer, etc. Deformation, the effect of preventing short circuit between electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] 100 parts by weight of polyisobutylene rubber with a weight average molecular weight of 1,000,000 (trade name "Oppanol B100EP", produced by BASF Japan Ltd.), 20 parts by weight of polyisobutylene rubber with a weight average molecular weight of 300,000 (trade name "Oppanol B30SF", BASF Japan Ltd.) was diluted to obtain a coating solution (1).

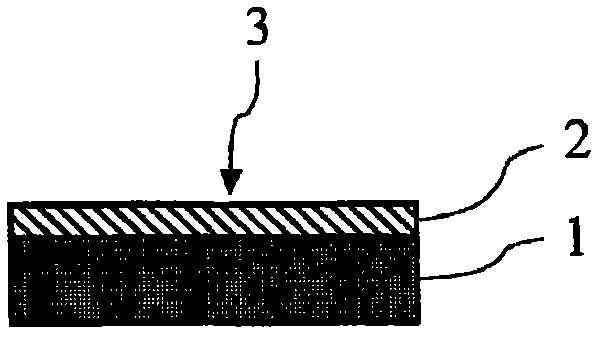

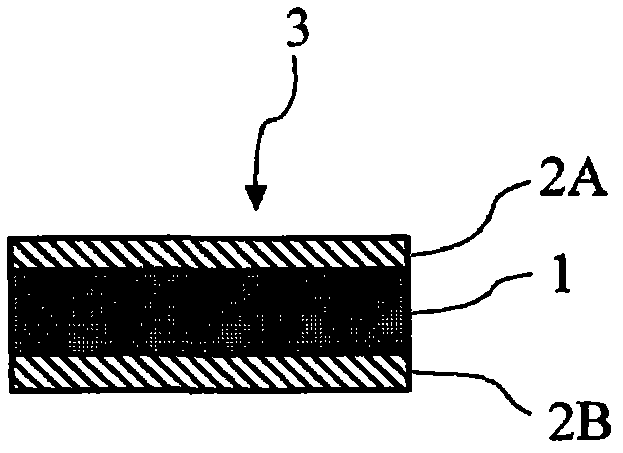

[0082] The obtained coating liquid (1) was coated on a polyimide film having a thickness of 25 μm so that the thickness after drying was 5 μm, and dried to obtain an adhesive tape (1) having the following adhesive layer (1). ) (water absorption: 1.4% by weight, volume resistivity: 1.3×10 17 Ω·cm).

[0083] adhesive layer (1)

[0084] Content of polyisobutylene rubber: 100% by weight

[0085] Content of polyisobutylene rubber with a molecular weight of 800,000 to 2.2 million: 27% by weight

[0086] Content of polyisobutylene rubber with a molecular weight of 10,000 to 700,000: 63% by weight

[0087] Content of components with...

Embodiment 2

[0089] 100 parts by weight of polyisobutylene rubber with a weight average molecular weight of 1,000,000 (trade name "Oppanol B100EP", manufactured by BASF Japan Ltd.), 30 parts by weight of polyisobutylene rubber with a weight average molecular weight of 120,000 (trade name "Oppanol B12SF", BASF Japan Ltd.) was diluted to obtain a coating liquid (2).

[0090] The obtained coating solution (2) was coated on a polypropylene film having a thickness of 20 μm and dried so that the thickness after drying was 15 μm, whereby an adhesive tape (2) having the following adhesive layer (2) was obtained ( Water absorption: 0.02% by weight, volume resistivity: 2.1×10 16 Ω·cm).

[0091] Adhesive Layer (2)

[0092] Content of polyisobutylene rubber: 100% by weight

[0093] Content of polyisobutylene rubber with a molecular weight of 800,000 to 2.2 million: 23% by weight

[0094] Content of polyisobutylene rubber with a molecular weight of 10,000 to 700,000: 68% by weight

[0095] Content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com