Adhesive tape for electrochemical device

An adhesive tape, electrochemical technology, used in electrochemical generators, adhesive types, ester copolymer adhesives, etc., can solve the problems of easy degradation of battery characteristics, degradation of battery characteristics, insufficient adhesion, etc. , to achieve the effect of inhibiting electrolyte deterioration, low moisture content, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Mix 97 parts by weight of isononyl acrylate, 3 parts by weight of acrylic acid, 0.1 parts by weight of 2,2'-azobisisobutyronitrile (AIBN) as an initiator, and 100 parts by weight of ethyl acetate as a solvent for 2 hours. N 2 replacement. in N 2 Under substitution, polymerization was performed at 60° C. for 6 hours to obtain an acrylic polymer (1) with a weight average molecular weight of 500,000.

[0089] A trifunctional isocyanate compound (trade name "CORONATE L", manufactured by Nippon Polyurethane Co., Ltd.) was blended into the obtained acrylic polymer (1) at a ratio of 5 parts by weight relative to the solid content to obtain an acrylic adhesive. agent (1).

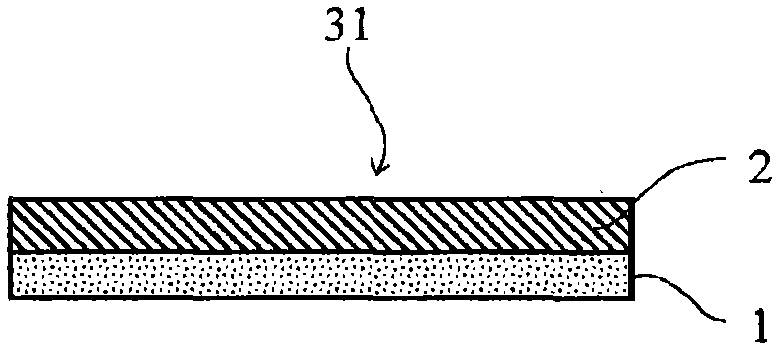

[0090] The obtained acrylic adhesive (1) was coated on a polypropylene film (trade name "TORAYFAN BO #2548", manufactured by Toray Industries, Inc., thickness: 20 μm) as a base material so that the thickness after drying was 5 μm , dried to obtain an adhesive tape (1).

Embodiment 2

[0092] Cooperate with 98 parts by weight of isooctyl acrylate, 2 parts by weight of hydroxyethyl acrylate, 0.1 parts by weight of AIBN, and 100 parts by weight of toluene as a solvent, and carry out 2 hours of N 2 replacement. in N 2 Under substitution, polymerization was performed at 60° C. for 6 hours to obtain an acrylic polymer (2) with a weight average molecular weight of 500,000.

[0093] To the obtained acrylic polymer (2), a trifunctional isocyanate compound (trade name "CORONATE L", manufactured by Nippon Polyurethane Co., Ltd.) was blended in a ratio of 4 parts by weight relative to the solid content to obtain an acrylic adhesive. agent (2).

[0094] The obtained acrylic adhesive (2) was coated on a polypropylene film (trade name "TORAYFAN BO #2548", manufactured by Toray Industries, Inc., thickness: 20 μm) as a base material so that the thickness after drying was 10 μm , dried to obtain an adhesive tape (2).

Embodiment 3

[0096] Cooperate with 95 parts by weight of 2-ethylhexyl acrylate, 5 parts by weight of acrylic acid, 0.1 parts by weight of AIBN, and 100 parts by weight of ethyl acetate for 2 hours of N 2 replacement. in N 2 Under substitution, polymerization was performed at 60° C. for 6 hours to obtain an acrylic polymer (3) with a weight average molecular weight of 800,000.

[0097] A trifunctional isocyanate compound (trade name "CORONATE L", manufactured by Nippon Polyurethane Co., Ltd.) was blended into the obtained acrylic polymer (3) in a ratio of 3 parts by weight relative to the solid content to obtain an acrylic adhesive. agent (3).

[0098] The obtained acrylic adhesive (3) was coated on a polypropylene film (trade name "TORAYFAN BO #2548", manufactured by Toray Industries, Inc., thickness: 30 μm) as a base material so that the thickness after drying was 5 μm , dried to obtain an adhesive tape (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com