4-methyl-1-pentene polymer, 4-methyl-1-pentene polymer-containing resin composition, master batch thereof, and molded articles of same

A technology of resin composition and polymer, which is applied in the direction of synthetic resin layered products, polyamide coatings, layered products, etc., and can solve problems such as agglomeration, wide range, and sliding agent whitening products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0354] The preparation method of 4.4-methyl-1-pentene polymer

[0355] The production method of the 4-methyl-1-pentene polymer described in the first aspect, the second aspect and the third aspect of the present invention will be described.

[0356] The 4-methyl-1-pentene polymer described in the first scheme, the second scheme and the third scheme of the present invention can be obtained by direct polymerization of olefins, or can be obtained by high molecular weight 4-methyl-1- 1-Pentene-based polymers are obtained by thermal decomposition. In addition, the above-mentioned 4-methyl-1-pentene can be obtained by using methods such as solvent fractionation for fractionation using the difference in solubility of solvents, or molecular distillation for separation using differences in boiling points. Olefin polymers are refined.

[0357] The preparation of the 4-methyl-1-pentene polymer used in the present invention preferably uses a currently known catalyst, such as JP-A-57-6331...

Embodiment

[0422] Hereinafter, although this invention is demonstrated more concretely based on an Example, this invention is not limited to these Examples.

[0423] In the present invention and Examples, unless otherwise specified in the specification, the properties were measured according to the following methods.

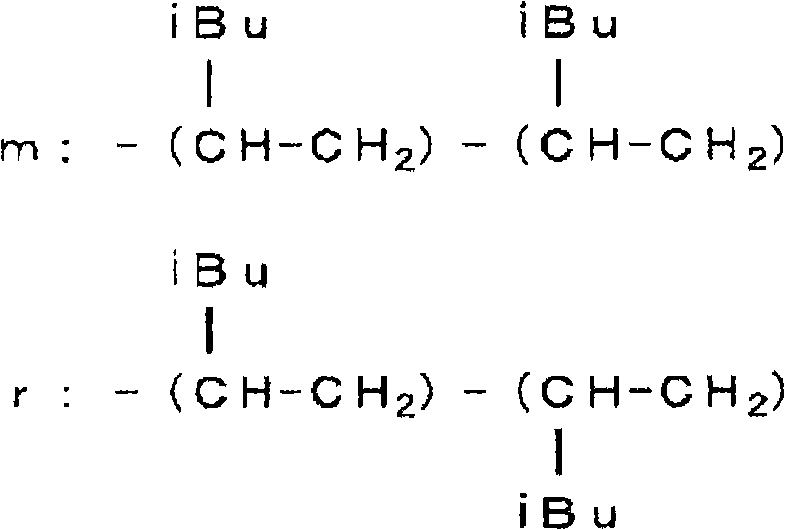

[0424] [composition]

[0425] Determined from the analysis of the 13C-NMR spectrum.

[0426] [Limited Viscosity]

[0427] Measured at 135°C using a decalin solvent. About 20 mg of the sample was dissolved in 15 ml of decalin, and the specific viscosity ηsp was measured in an oil bath at 135°C. After adding 5 ml of decalin solvent to the decalin solution and diluting it, the specific viscosity ηsp was measured in the same manner. This dilution operation was repeated twice more, and the value of ηsp / C when the concentration (C) was extrapolated to 0 was obtained as the intrinsic viscosity.

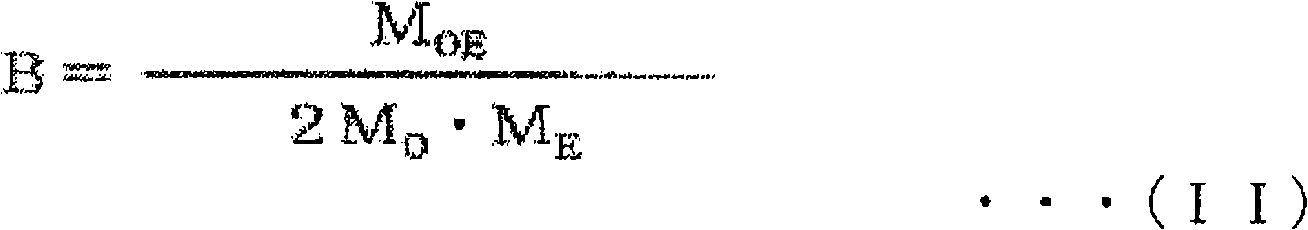

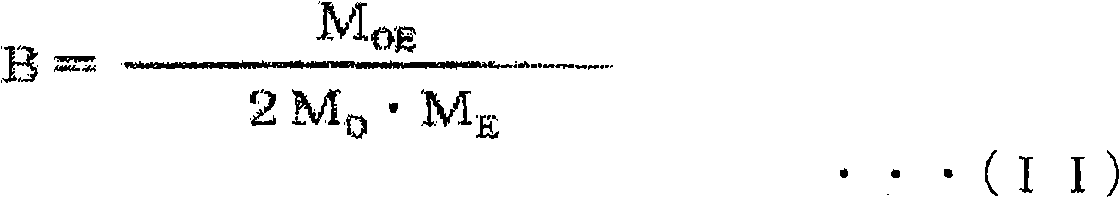

[0428] [η]=lim(ηsp / C)(C→0[molecular weight])

[0429] [The molecular weight di...

Embodiment 20~22 and

[0455] [Releasability] (Examples 20-22 and Reference Examples 5-8)

[0456] In 100 parts by mass of polypropylene resin (Prime Polypro F113G, manufactured by Prime Polymer Co., polypropylene homopolymer, melt flow rate = 3 g / 10 minutes), 3 parts by mass of 4-methyl-1-pentane were mixed (dry blended) vinyl polymers. Next, the resulting mixture was put into a T-die equipped with a lip width of 240 mm. In the single-screw extruder (manufactured by Tanaka Iron Works Co., Ltd.), the cylinder temperature was set at 230° C. and the die temperature was set at 230° C., and the molten kneaded product was extruded from the T die. Thereafter, the extruded melt-kneaded product was pulled at a cooling roll temperature of 40° C. at a pulling speed of 1.0 m / min to obtain a cast film (Cast film) having a thickness of 50 μm.

[0457] 10 parts by mass of a polyamide resin (Amilan CM1041LO; manufactured by Toray Co., Ltd.) was mixed (dry blended) with 10 parts by mass of a 4-methyl-1-pentene-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| critical surface tension | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com