Thermoelectric conversion material and thermoelectric conversion element

A thermoelectric conversion material and thermoelectric conversion technology, applied in the fields of thermoelectric conversion materials and thermoelectric conversion elements, can solve the problem that the thermoelectric conversion efficiency of thermoelectric conversion materials cannot be said to be sufficient, and achieve the effects of excellent thermoelectric conversion performance and excellent thermoelectric potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0255] Then, 10 mg of the conductive polymer 1 shown below (manufactured by Aldrich, weight average molecular weight = 87000), 2 mg of the above-mentioned thermal activation auxiliary agent 401, and 4 mg of CNT (ASP-100F, manufactured by Hanwha Nanotech Co., Ltd.) were added to 5 ml of o-dichlorobenzene , using an ultrasonic water bath to disperse for 70 minutes. Thereafter, 4 mg of the following dopant 107 was added and fully dissolved to prepare a mixed liquid. The mixed liquid was coated on a glass substrate, and the coated product was heated at 120° C. for 15 minutes to distill off the solvent, and then dried under vacuum at room temperature for 10 hours to produce a thermoelectric conversion film with a film thickness of 2.5 μm. Thereafter, the film was irradiated with ultraviolet light (light intensity: 1.06 J / cm 2 ) for doping with conductive polymers. The presence or absence of doping was confirmed by the following method.

[0256] For the obtained film for thermoel...

Embodiment 2~29、 comparative example 1~9

[0271] Examples 2 to 29 and Comparative Example 1 were produced in the same manner as in Example 1, except that the type and presence or absence of the conductive polymer, thermal excitation assistant, and dopant were changed as shown in Table 1 or Table 2. ~9 films for thermoelectric conversion were evaluated. The results are listed in Table 1 and Table 2.

[0272]

[0273]

[0274] Tables 1 and 2 clearly show that the energy level of LUMO of the thermal activation auxiliary agent and the energy level of HOMO of the conductive polymer satisfy the above formula (I) in Examples 1 to 29, all of which have excellent thermoelectric properties. On the other hand, in Comparative Examples 2 to 4 that did not satisfy the above formula (I) and Comparative Examples 1 and 6 to 9 that did not use a thermal activation auxiliary agent, the thermoelectric characteristics were significantly lowered compared with the Examples.

Embodiment 30

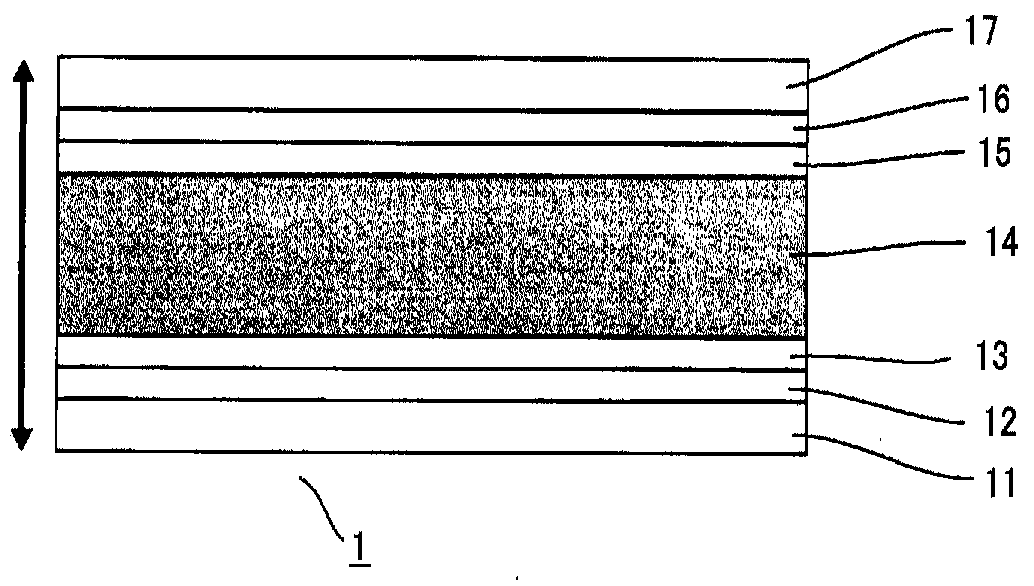

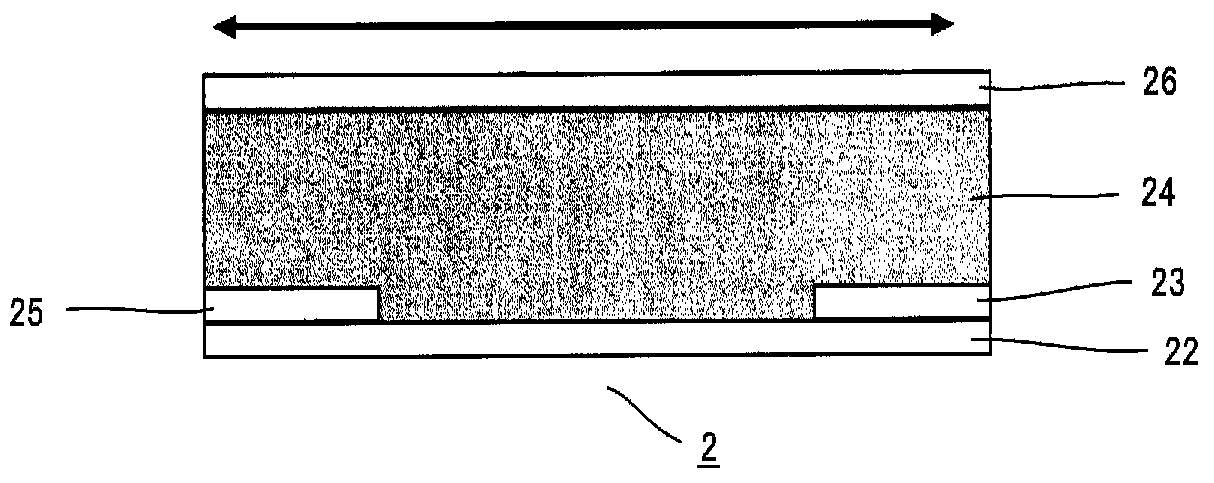

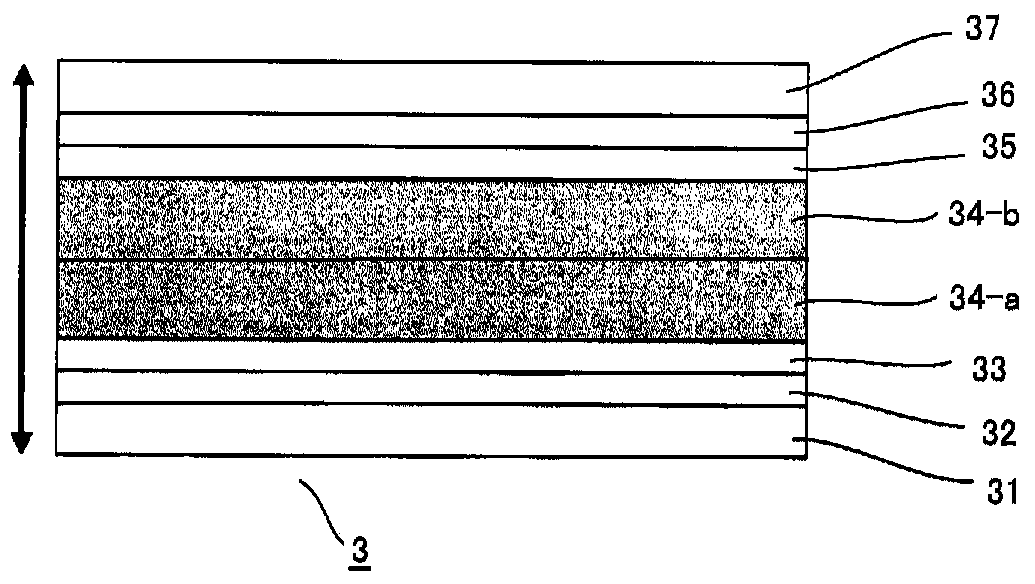

[0276] On a glass substrate having an ITO electrode (thickness: 10 nm) as the first electrode, the mixed solution prepared in Example 1 was coated, and the coated product was heated at 95° C. for 20 minutes to distill off the solvent, and the resulting material was heated at room temperature It was dried under vacuum for 4 hours to form a first thermoelectric conversion layer having a film thickness of 2.9 μm. Thereafter, the layer was irradiated with ultraviolet rays (light quantity: 1.06 J / cm 2 ) for doping with conductive polymers.

[0277] Next, on the top of the first thermoelectric conversion layer, the mixed solution prepared in Example 7 was coated in the same manner, and the solvent was distilled off by heating at 95° C. for 20 minutes, and the obtained material was dried under vacuum at room temperature for 4 hours to form the first thermoelectric conversion layer. The second thermoelectric conversion layer. Thereafter, the layer was irradiated with ultraviolet ray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com