T-shaped steam-water separator

The technology of a steam-water separator and a water storage tank is applied in the directions of separation method, dispersed particle separation, chemical instrument and method, etc., which can solve the problems of system pressure relief, high sensible heat waste in condensate water, internal heat consumption, etc., and improve the steam supply. Quality, the effect of solving high sensible heat waste in water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

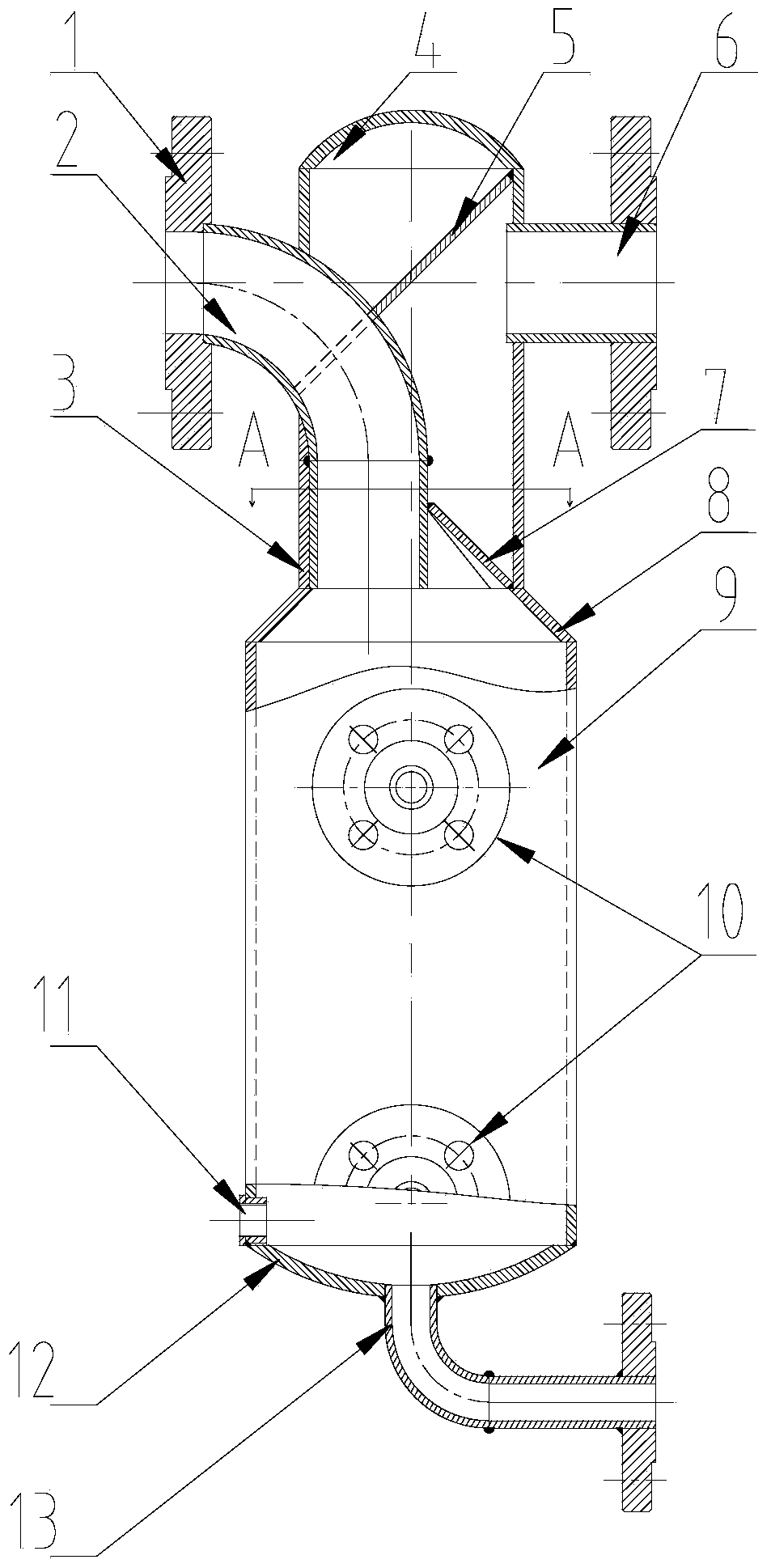

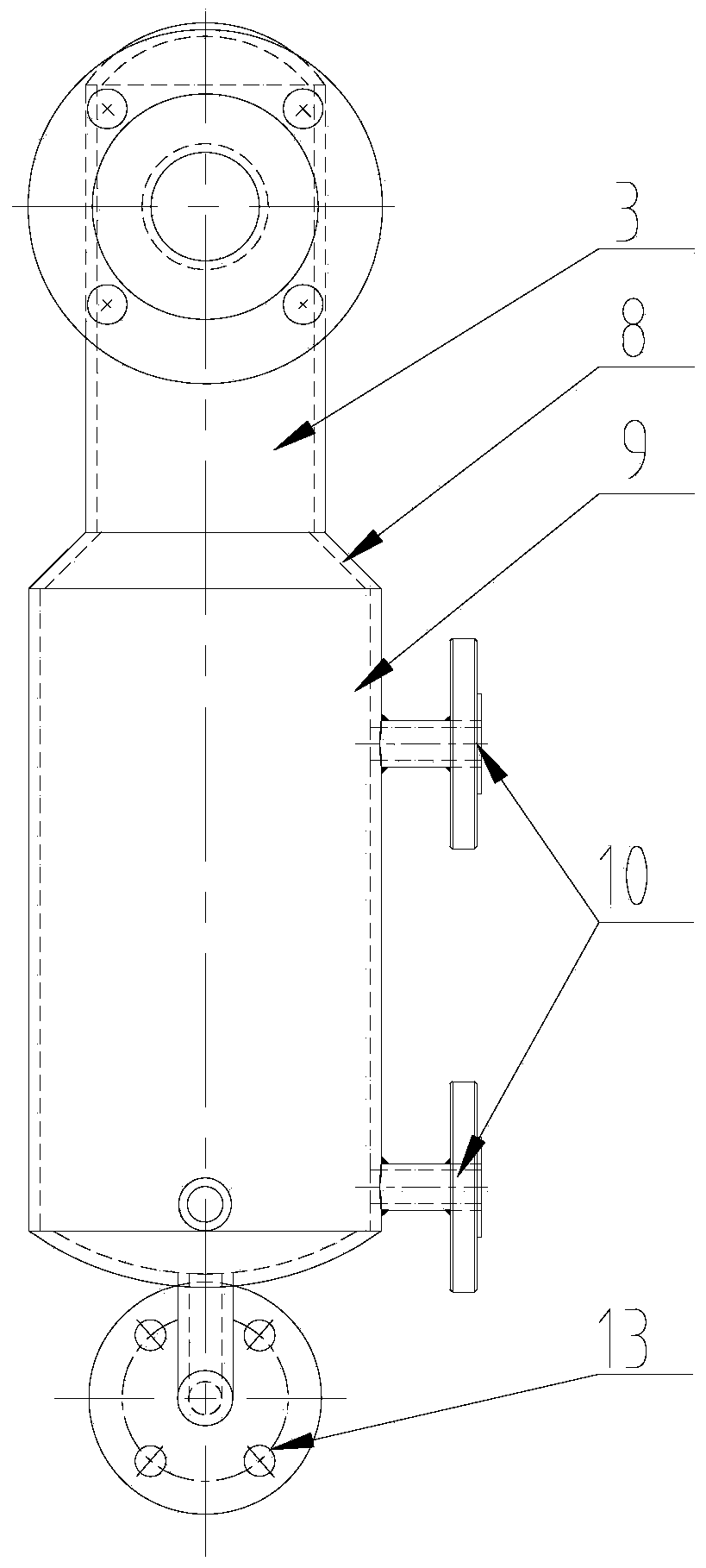

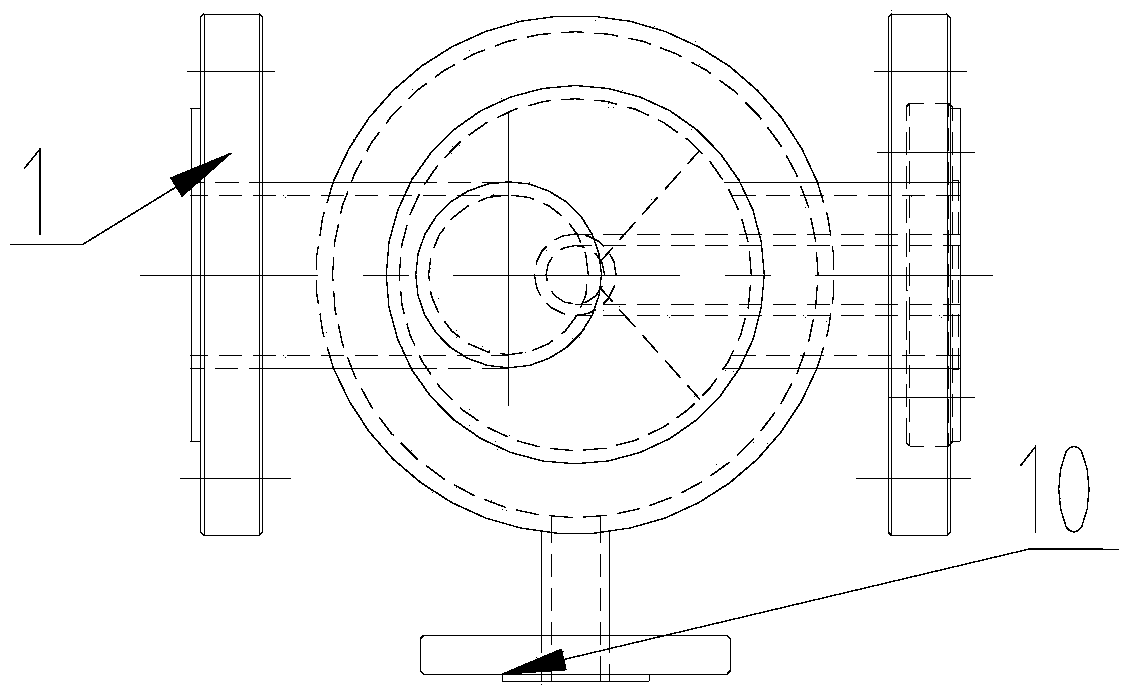

[0024] The T-type steam-water separator is installed at the end of the steam supply pipeline. Since the amount of condensed water in the steam supply pipeline changes with the operating status, the overall design of the T-type steam-water separator installed at the end of the steam supply pipeline consists of three parts. :

[0025] (1) T-type steam separator body; (2) Condensed water data collection and control; (3) Condensed water discharge system.

[0026] (1) T-type steam-water separator body: When the steam supply system starts to work, the steam and condensed water enter through the entrance of the T-type steam-water separator body and turn to vertically sink into the lower part of the T-type, and the steam turns upward for steam-water separation. Steam is exhausted through the outlet. The condensed water is connected to the discharge system through the T-shaped bottom of the separator;

[0027] See details Figure 5 , (ii) Condensate water data collection and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com