High-wear-resistance red Guimo brick and preparation technique thereof

A silicon mullite brick and a preparation process technology, applied in the field of refractory materials, can solve the problems of insufficient bonding strength, incomplete development of mullite crystals, wear resistance, high temperature resistance and thermal shock resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

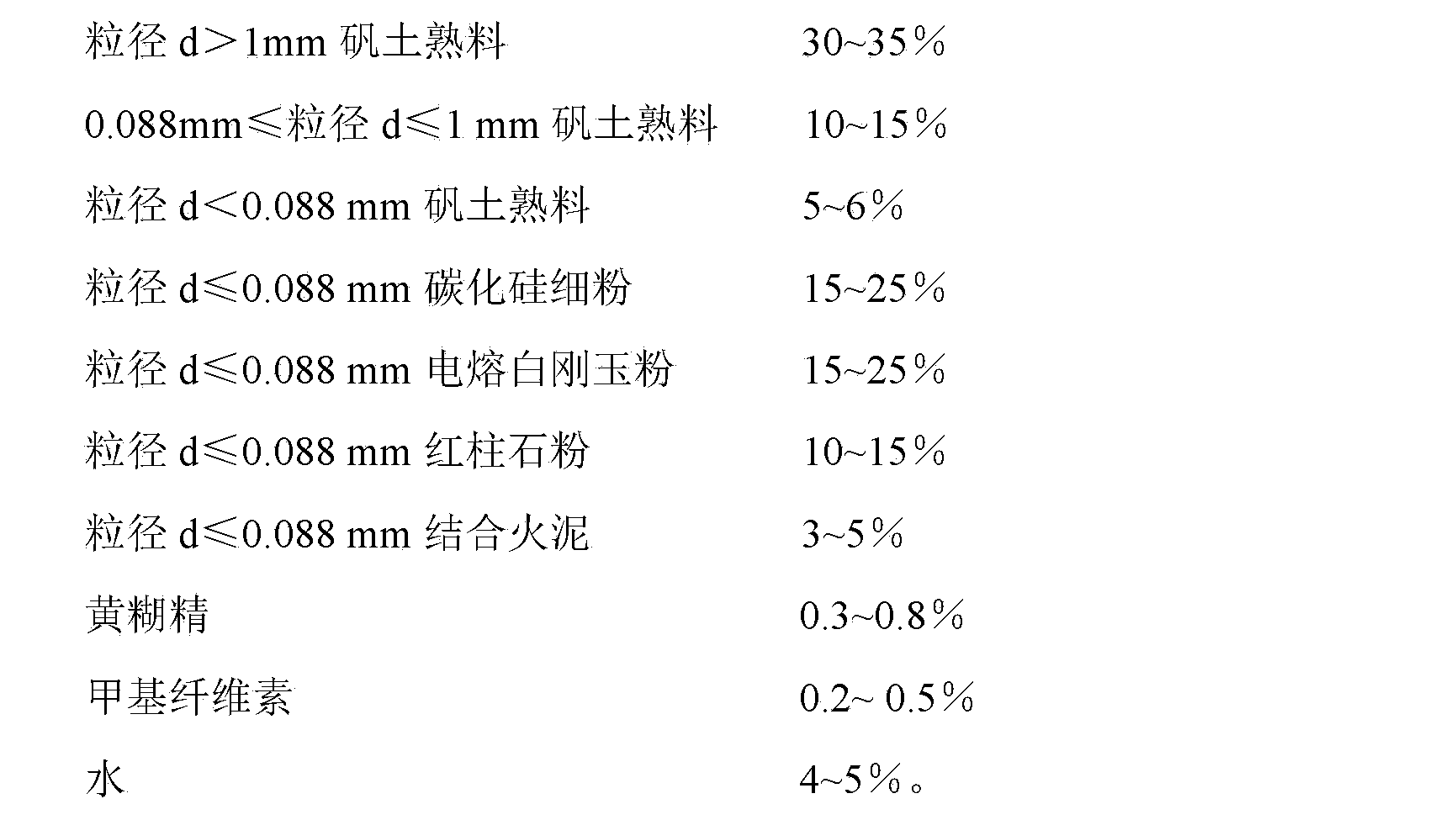

[0019] A high wear-resistant silica molybdenum brick is prepared from the following components in weight percent:

[0020]

[0021] Wherein, described bauxite clinker is Al 2 o 3 The weight percentage is 88% special-grade bauxite clinker; the described silicon carbide fine powder is silicon carbide fine powder with a SiC weight percentage of 95%; the described fused white corundum powder is Al 2 o 3 The electric fused white corundum powder that weight percentage is 99.3%; Described andalusite powder is Al 2 o 3 The andalusite powder that weight percent composition is 59%; Described bonding fire clay is Al 2 o 3 The weight percentage is 40% combined fire clay.

[0022] The above-mentioned raw materials are weighed according to the proportion, then put into the forced mixer and mixed well, and kneaded to make mud; use a friction brick press to press the mud under a pressure of 650KN to obtain adobe; the formed adobe is dried Dry in the kiln at 150°C for 15 hours to rem...

Embodiment 2

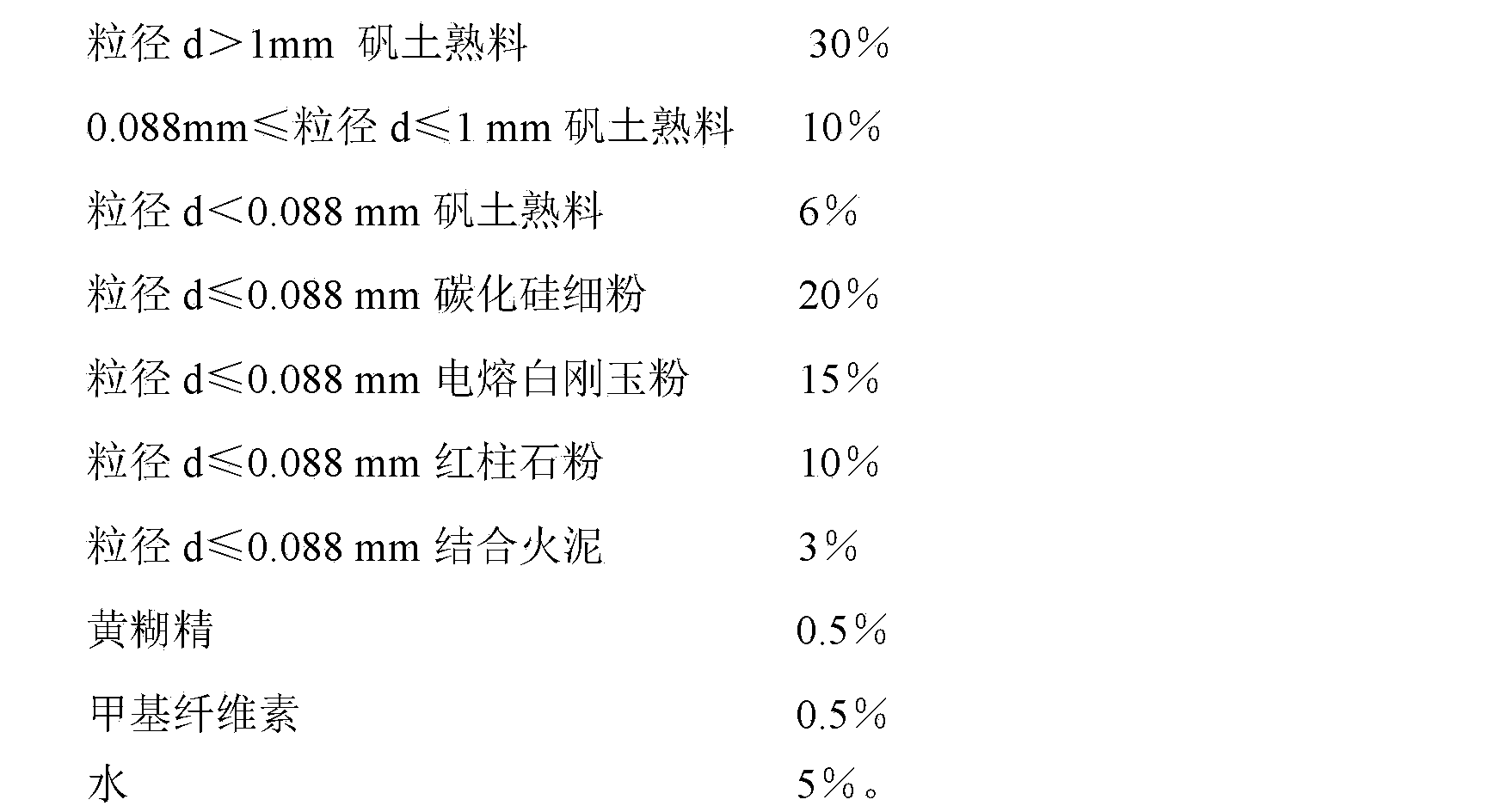

[0025] A high wear-resistant silica molybdenum brick is prepared from the following components in weight percent:

[0026]

[0027] Wherein, described bauxite clinker is Al 2 o 3 The weight percentage is 89% special-grade bauxite clinker; the described silicon carbide fine powder is silicon carbide fine powder with a SiC weight percentage of 94%; the described fused white corundum powder is Al 2 o 3 The electric fused white corundum powder that weight percentage is 99.4%; Described andalusite powder is Al 2 o 3 The andalusite powder that weight percent composition is 58.6%; Described bonding fire clay is Al 2 o 3 The weight percentage is 38.5% combined fire clay.

[0028] The above-mentioned raw materials are weighed according to the proportion, then put into the forced mixer and mixed well, and kneaded to make mud; use a friction brick press to press the mud under a pressure of 650KN to obtain adobe; the formed adobe is dried Dry in the kiln at 100°C for 20 hours to...

Embodiment 3

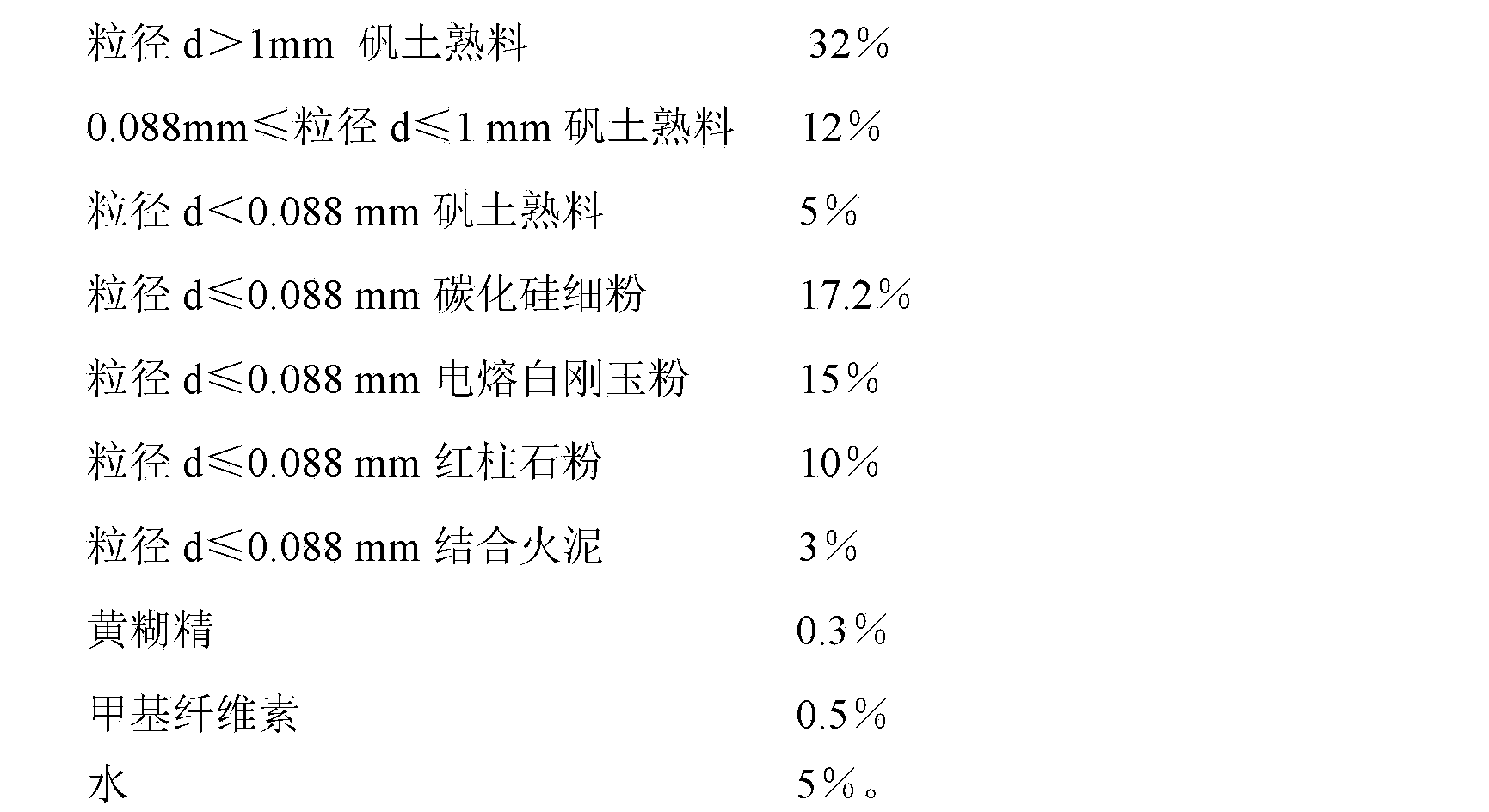

[0031] A high wear-resistant silica molybdenum brick is prepared from the following components in weight percent:

[0032]

[0033]

[0034] Wherein, described bauxite clinker is Al 2 o 3 The weight percentage is 90% special-grade bauxite clinker; the described silicon carbide fine powder is silicon carbide fine powder with a SiC weight percentage of 93%; the described fused white corundum powder is Al 2 o 3 The electric fused white corundum powder that weight percentage is 99.6%; Described andalusite powder is Al 2 o 3 The andalusite powder that weight percent composition is 58.6%; Described bonding fire clay is Al 2 o 3 The weight percentage is 38.7% combined fire clay.

[0035] The above-mentioned raw materials are weighed according to the proportion, then put into the forced mixer and mixed well, and kneaded to make mud; use a friction brick press to press the mud under a pressure of 650KN to obtain adobe; the formed adobe is dried Dry in the kiln at 170°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Normal temperature compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap