Sheathing arrangement for a soil-working roller, in particular for a self-propelled soil compactor

A technology of cladding device and compactor, applied in soil protection, infrastructure engineering, roads, etc., can solve time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

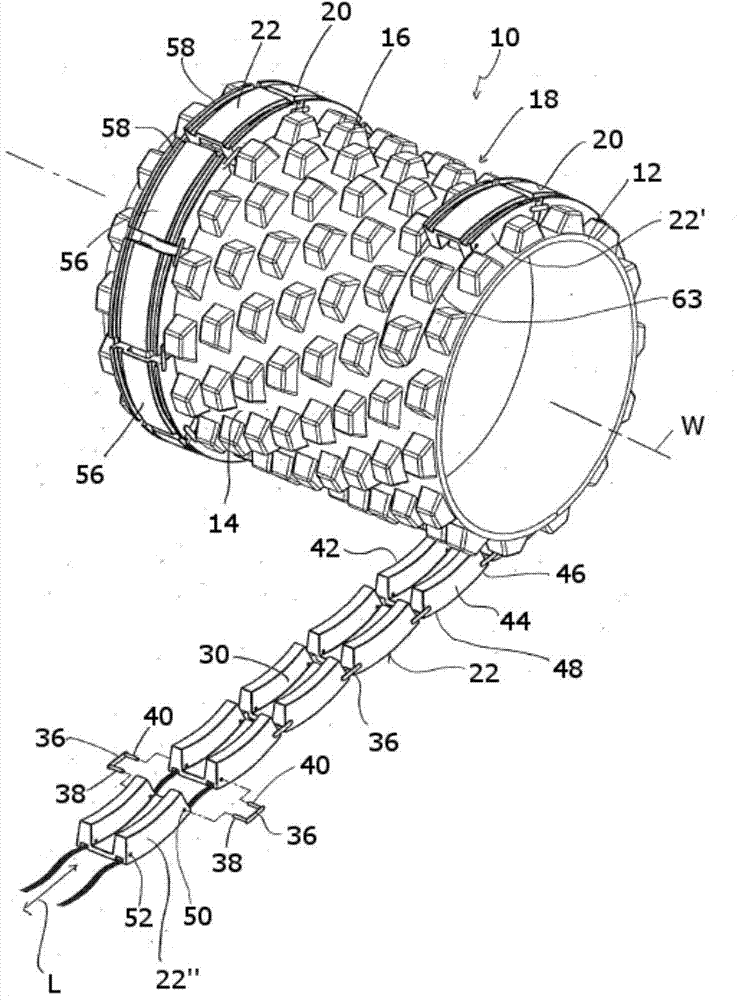

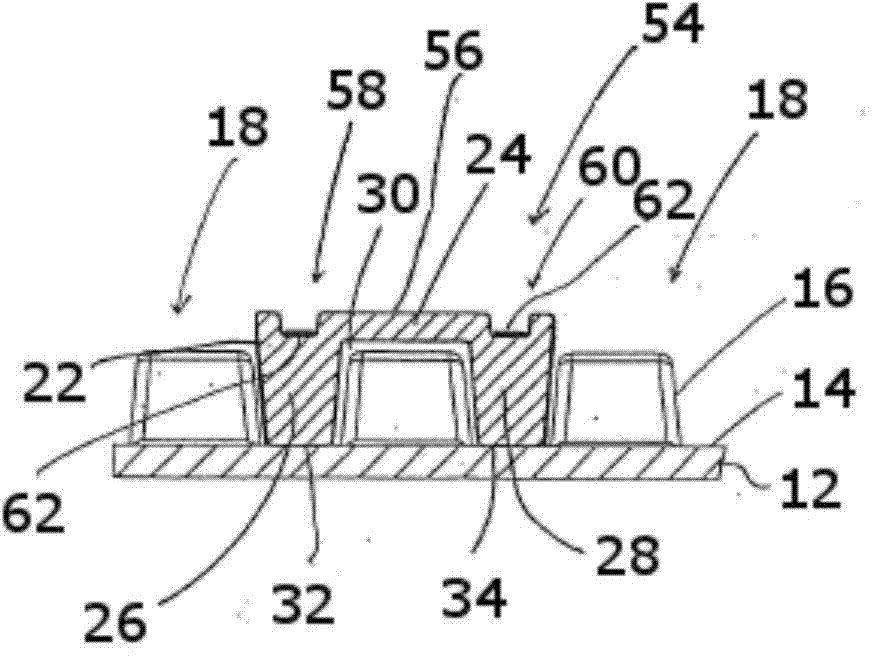

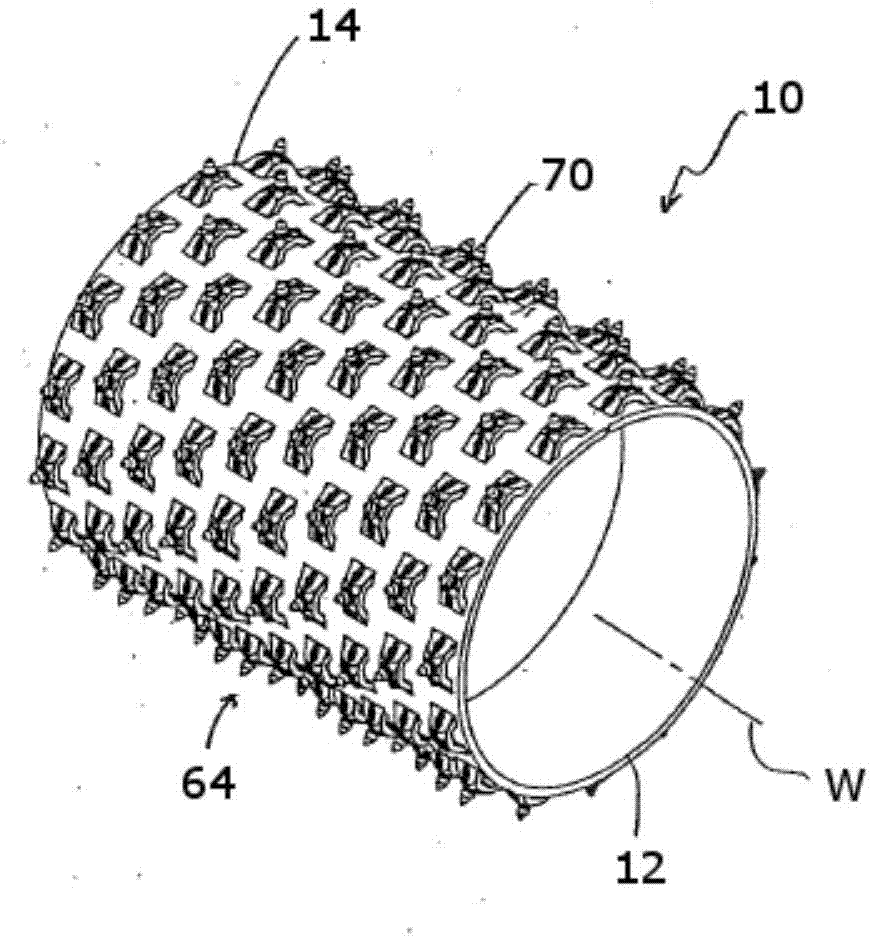

[0031] exist figure 1 shows a ground working roller 10 that can be used, for example, on a self-propelled ground compactor. The floor working roller 10 extending longitudinally in the direction of the roller longitudinal axis W and generally formed with a cylindrical structure comprises a roller mantle 12, and on the outer surface 14 of the roller mantle 12 comprises a plurality of Rolling tool 16 configured in the manner of a tamping foot. They are arranged, for example, at a substantially constant circumferential distance from one another in a number of successive rolling tool rings 18 in the direction of the longitudinal axis W of the roll, wherein the rolling tools 16 arranged in the immediately adjacent rolling tool rings 18 can be positioned offset from one another in the circumferential direction.

[0032] exist figure 1 The floor working roller 10 shown is provided with two covering devices 20 . exist figure 1 The covering device 20 , which is arranged on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com