Integral lifting method for ultra-long light thin giant steel tube truss

A steel pipe truss and overall lifting technology, which is applied in the construction, building structure, construction material processing and other directions, can solve the problems of many cross operations and short construction period, and achieves saving construction costs, improving orientation, and good social and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The overall lifting method of the ultra-long, light and thin giant steel pipe truss of the present invention comprises the following steps in sequence:

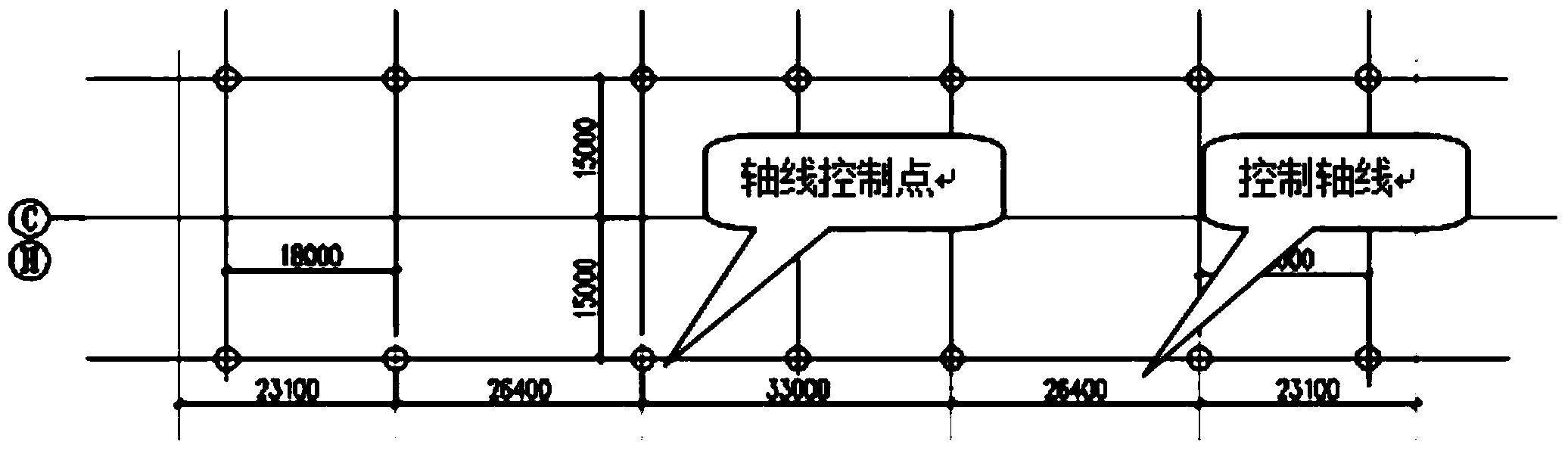

[0016] a) First, on the floor, set control lines along the C-axis offset by 15m to both sides, as the assembly control axis along the X direction, and set 6 Y-direction control lines along the direction perpendicular to the C-axis to form an assembly control axis network ;

[0017] b) Then install the temporary tire frame, the assembled tire frame is welded together with the steel plate pre-embedded on the concrete beam, and fixed firmly;

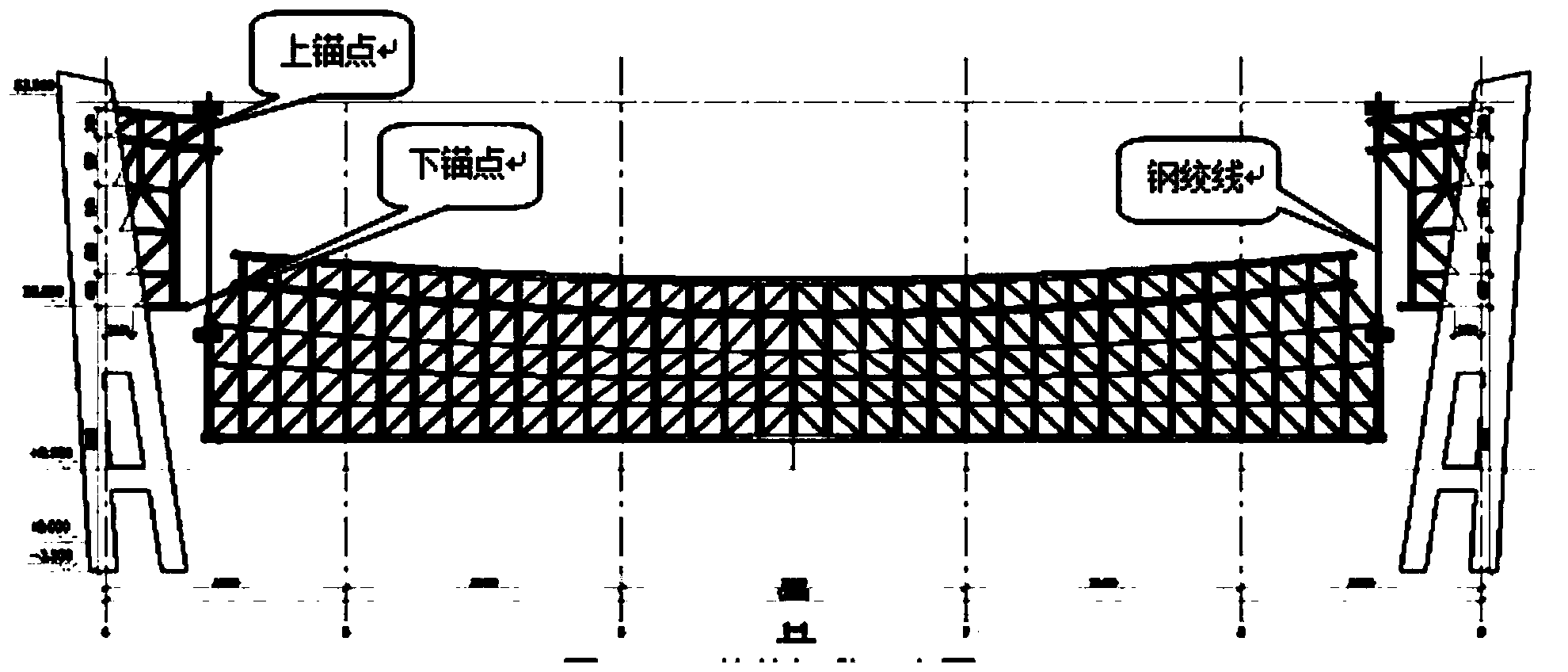

[0018] c) Then set up the support guide frame. One set of support frame uses two 1.28x1.28m lattice standard sections with a height of 21m. There are 5 sets in total. One set of guide frame uses two 1.28x1.28m lattice standard sections. The height is about 2m higher than the lifting height, a total of 4 groups, and the foundation is just connected to the concrete root;

[0019] d)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com