Semiconductor sheet surface defect and thickness detection device and method

A thickness detection and semiconductor technology, which is applied in the field of surface defects of semiconductor sheets and thickness detection devices, can solve the problems of the influence of the measurement accuracy of the thickness detection device of semiconductor sheets, the reduction of the reception rate of reflected light, the reduction of the arrival rate of emitted light, and the like. The effect of reducing losses, increasing density, and reducing performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

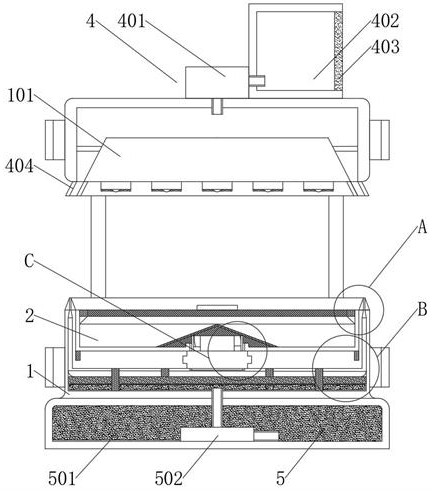

[0041] The invention discloses a surface defect and thickness detection device of a semiconductor sheet. Figure 1-Figure 3 As shown, it includes a detection base 1 , a dust collection mechanism 2 , an air wall mechanism 3 , a wind collection mechanism 4 and a synergistic mechanism 5 .

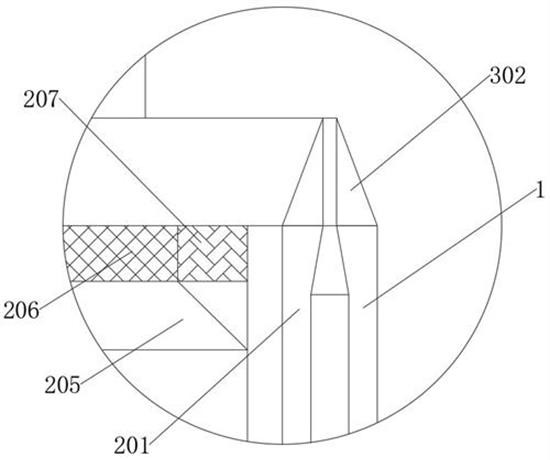

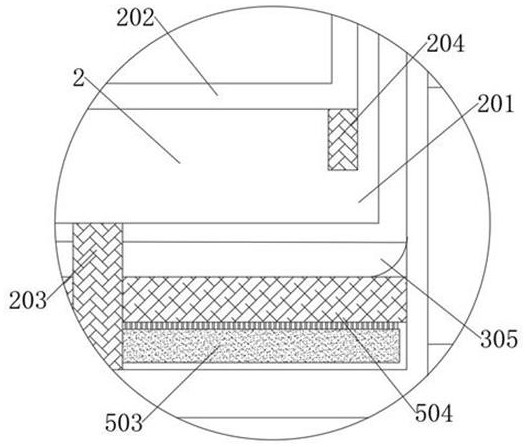

[0042] ginseng Figure 2-Figure 4 As shown, the detection base 1 is provided with a dust collection mechanism 2, the dust collection mechanism 2 includes a support base 201, and the support base 201 can form a uniform air cavity with the detection base 1 through the support of the cavity rod 203, and at the same time, the second A dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com