A carbon nanotube wire rod, a preparing method thereof, a preparing device and applications

A technology for carbon nanotubes and preparation devices, applied in chemical instruments and methods, carbon compounds, textiles and papermaking, etc., can solve the problems of complex preparation process, poor orientation of carbon nanotubes, and high production costs, and achieve improved stability and reliability. Controllability, improve the generation rate, improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

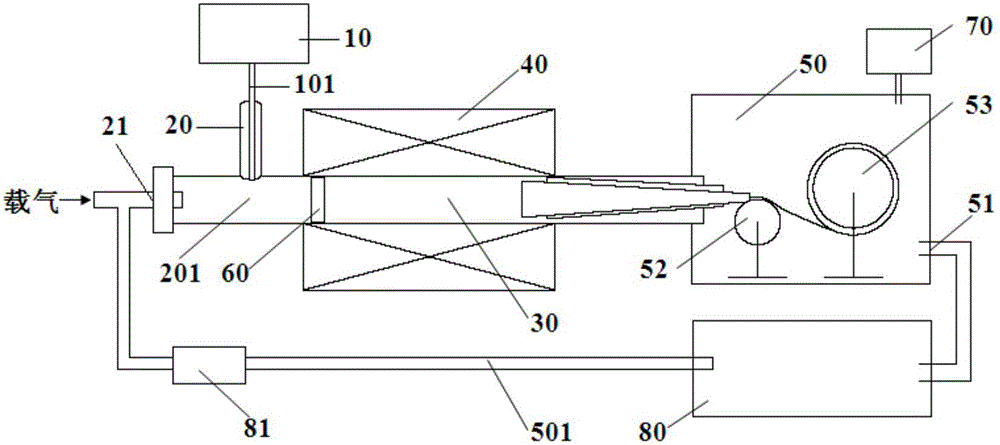

[0037] In another typical embodiment of the present application, a method for preparing a carbon nanotube wire is provided. The preparation method includes: mixing a liquid carbon source with a catalyst to form a raw material liquid; atomizing the raw material liquid to obtain an atomized Raw materials; and using the carrier gas to guide the flow direction of the atomized raw materials, and make the atomized raw materials undergo catalytic reactions under heating conditions to continuously generate carbon nanotube wires.

[0038] The principle of carbon nanotube preparation is that under the joint action of heating and catalyst, the liquid carbon source is decomposed into atomic carbon and precipitated on the surface of the catalyst to form carbon nanotubes.

[0039] The preparation reaction of carbon nanotubes after the liquid carbon source and the catalyst form a mixed solution is conducive to making the reaction raw materials more uniform, thereby improving the stability and...

Embodiment 1

[0065] The liquid carbon source tetrahydrofuran and the catalyst ferrocene are mixed according to the ratio of adding 150 mg of ferrocene catalyst per ml of tetrahydrofuran to prepare a raw material solution.

[0066] The above raw material solution was atomized at 50 kHz to obtain an atomized raw material.

[0067]Under the guidance of carrier gas with a rate of 9000 ml / min (the flow ratio of argon and hydrogen is 3:1) and a temperature of 1450 ° C, under the conditions of normal pressure, the above-mentioned atomized raw materials are subjected to a catalytic reaction to obtain carbon nanotube wires .

[0068] The above-mentioned carbon nanotube wires are collected using a carbon nanotube wire collection device. Among them, the density of carbon nanotube wire is 900kg / m 3 , Young's modulus is 250GPa, conductivity is 1.0×10 7 S m -1 , the maximum current load is 6000A / mm 2 , The tensile breaking strength is 1.5GPa.

Embodiment 2

[0070] The liquid carbon source xylene and the catalyst ferrocene are mixed according to the ratio of adding 50 mg of ferrocene catalyst per milliliter of xylene to prepare a raw material solution.

[0071] The above raw material solution was atomized at 50 kHz to obtain an atomized raw material.

[0072] Under the guidance of a carrier gas with a rate of 9000 ml / min (the flow ratio of argon and hydrogen is 3:1) and a temperature of 1150 ° C, under the conditions of normal pressure, the above-mentioned atomized raw materials are subjected to a catalytic reaction to obtain carbon nanotube wires .

[0073] The above-mentioned carbon nanotube wires are collected using a carbon nanotube wire collection device. Among them, the density of carbon nanotube wire is 750kg / m 3 , Young's modulus is 180GPa, conductivity is 8×10 6 S m -1 , the maximum current load is 5500A / mm 2 , The tensile breaking strength is 1.35GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com