Polygonal machining material positioning guiding device

A technology of positioning, guiding and processing materials, which is applied in positioning devices, metal processing, metal processing equipment, etc., can solve problems such as damage to fixtures, reduce processing efficiency, etc., and achieve the effect of guiding improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

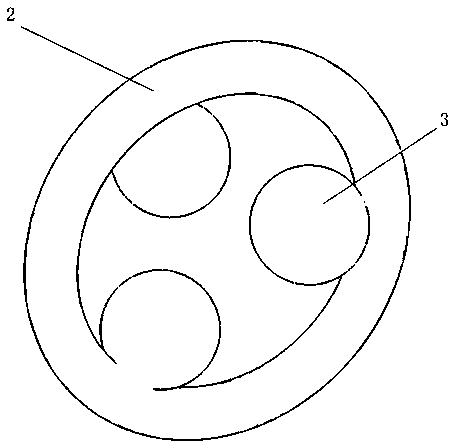

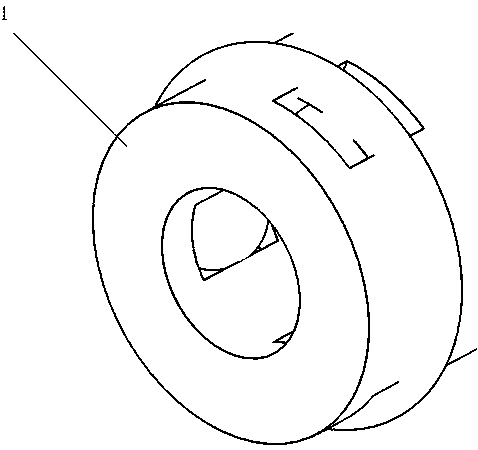

[0029] Such as Figure 1-3 As shown, a positioning and guiding device for polygonal processing materials, the positioning and guiding device is connected to the material pipe 1, and the positioning and guiding device includes an elastic body 2 and a guiding and locking mechanism 3;

[0030] The elastic body 2 is arranged in the groove provided on the material tube 1, and at least three guide locking mechanisms 3 are arranged on the inner side of the elastic body 2;

[0031] The guide locking mechanism 3 is fixedly connected to the inner side of the elastic body 2 at an angle, and the groove of the material tube 1 is provided with the same number of through holes 4 as the guide locking mechanism 3, and the guide locking mechanism 3 is installed In the through hole 4 , part of the guide locking mechanism 3 protrudes from the bottom surface of the through hole 4 .

[0032] The angle between the guide locking mechanisms 3 is 0-120°.

[0033] The depth of the through hole 4 is sm...

Embodiment 2

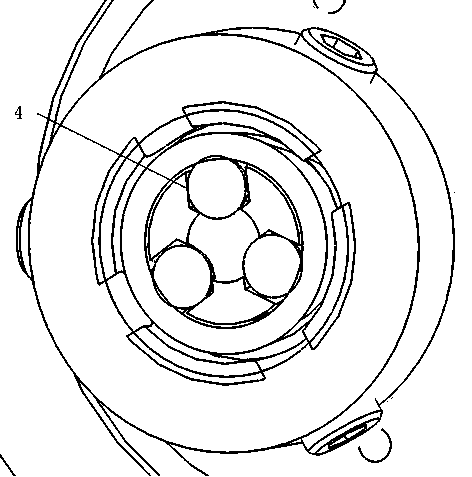

[0036] Such as Figure 4 As shown, a hexagonal prism processing material positioning and guiding device, the positioning and guiding device is connected with the material tube 1, and the positioning and guiding device includes an elastic body 2 and a guiding and locking mechanism 3;

[0037] The elastic body 2 is arranged in the groove provided on the material tube 1, and three guiding locking mechanisms 3 are arranged inside the elastic body 2, and the locking mechanisms can be spherical balls.

[0038] The three guiding and locking mechanisms are distributed at an angle of 120° and fixedly connected to the inner side of the elastic body 2, and the groove of the material tube 1 is provided with three through holes 4, and the guiding and locking mechanisms 3 are installed in the through holes 4, the guide locking mechanism 3 partially protrudes from the bottom surface of the through hole 4, the bottom surface of the through hole 4 is a hemispherical surface, the diameter of th...

Embodiment 3

[0041] An octagonal prism processing material positioning and guiding device, the positioning and guiding device is connected to the material pipe 1, and the positioning and guiding device includes an elastic body 2 and a guiding and locking mechanism 3;

[0042] The elastic body 2 is arranged in the groove provided on the material tube 1, and four guiding locking mechanisms 3 are arranged on the inside of the elastic body 2, and the locking mechanism can be any curved object including a spherical and semi-circular ball;

[0043] The four guiding and locking mechanisms are distributed at an angle of 90° and fixedly connected to the inner side of the elastic body 2. Four through holes 4 are arranged on the groove of the material tube 1, and the guiding and locking mechanisms 3 are installed on the through holes. In the hole 4, the guide locking mechanism 3 partially protrudes from the bottom surface of the through hole 4, the bottom surface of the through hole 4 is a hemispheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com