Axial flow type mine ventilator

A ventilator, axial flow technology, applied in mine/tunnel ventilation, mining equipment, mechanical equipment, etc., can solve the problems of high energy consumption, poor ventilation effect, complex structure, etc., and achieve low energy consumption and easy handling operation, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

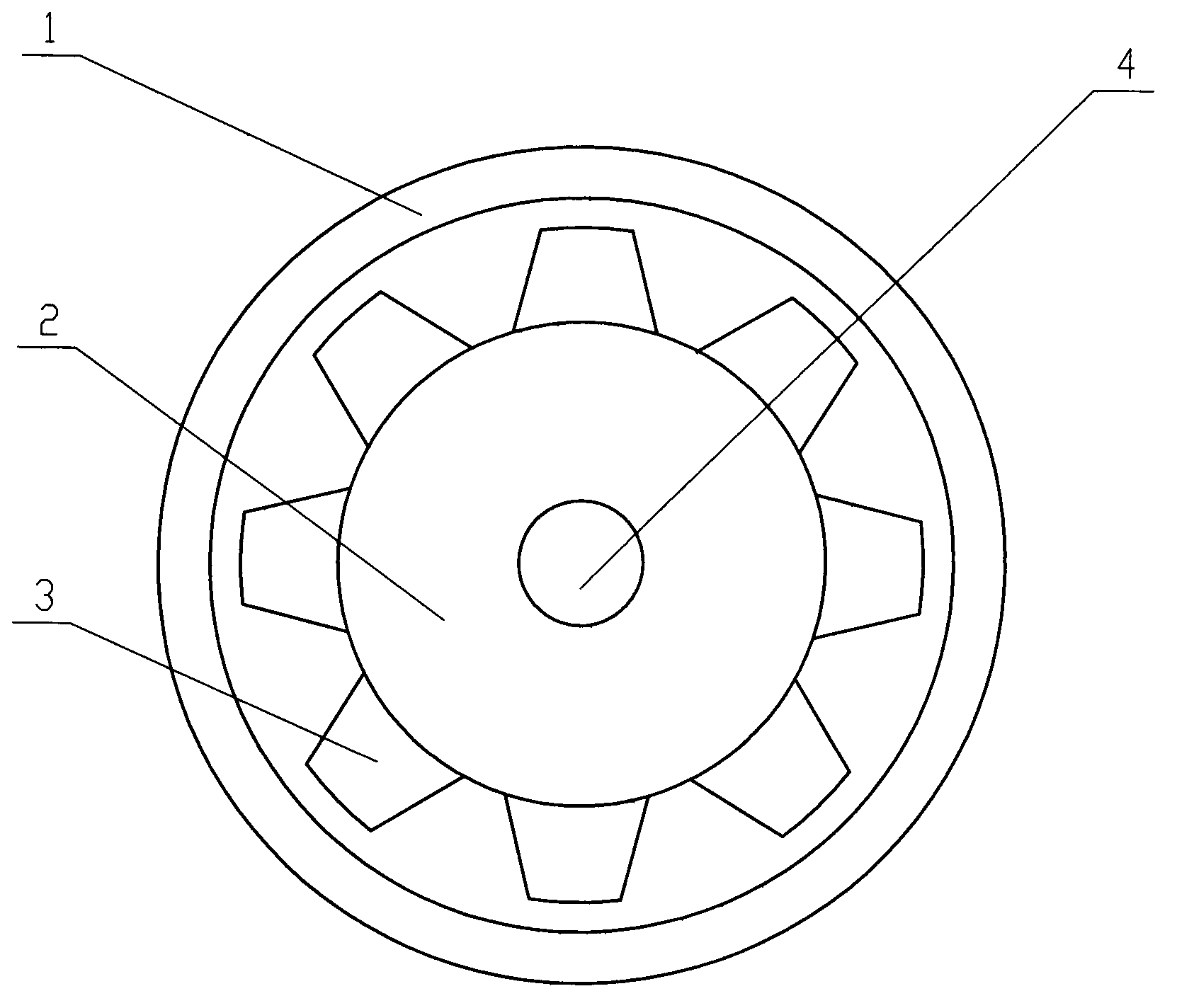

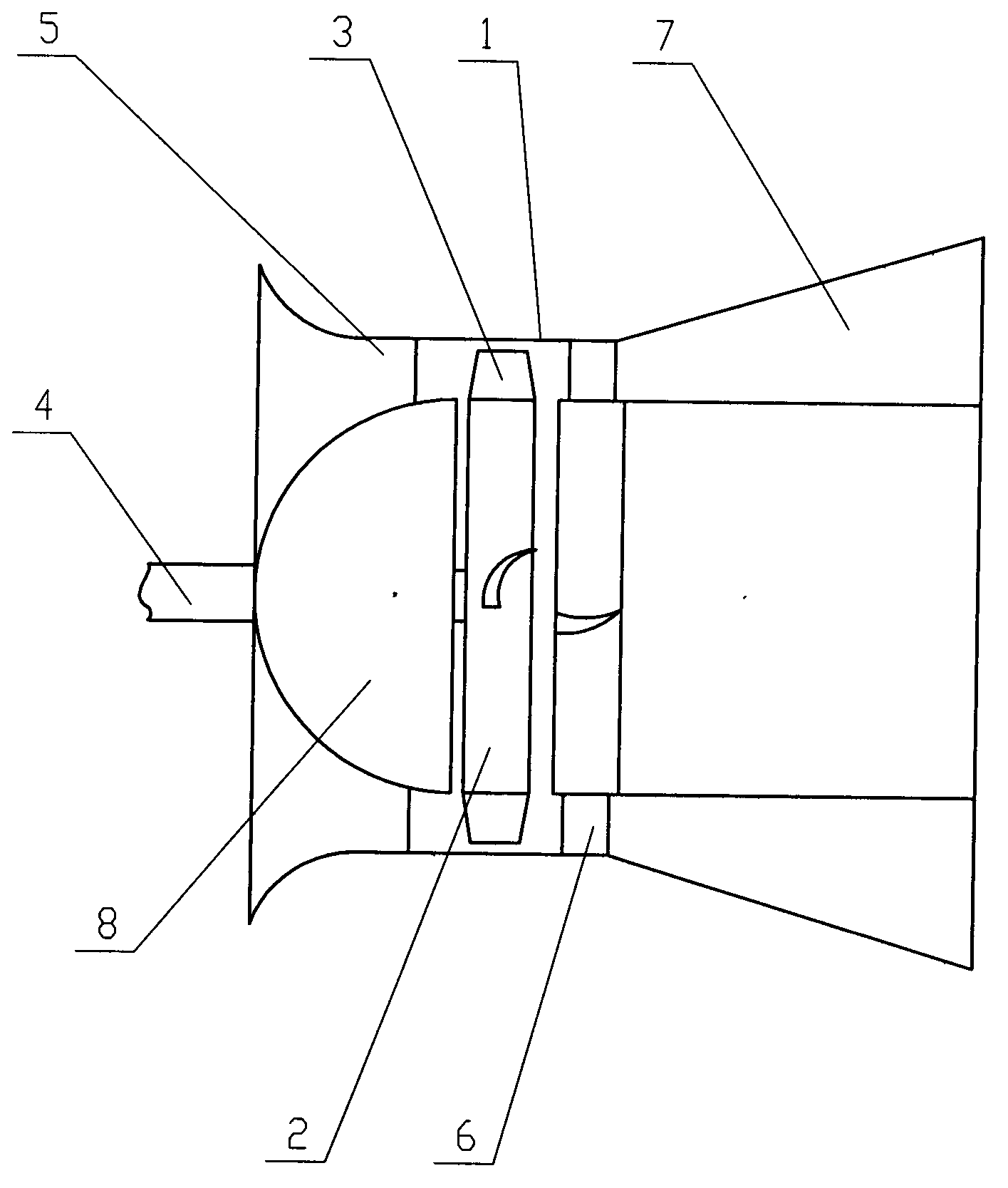

[0013] See figure 1 , figure 2 , the present invention comprises a crankshaft 4, a casing 1, an air collector 5 and an air diffuser 7 connected to the casing 1, the crankshaft 4 is fixedly connected to a hub 2, a streamlined body 8 and a rectifier 6, and the periphery of the hub 2 has a wheel The leaves 3 and the streamline body 8 are placed at the junction of the casing 1 and the air collector 5, the rectifier 6 is placed at the junction of the casing 1 and the air diffuser 7, and the hub 2 is placed in the casing 1 and located at the streamline body 8 and rectifier 6. The streamline body 8 is hemispherical, and the air collector 5 is conical, both of which contribute to the entry of air, and the rectifier 6 and the conical air diffuser 7 both contribute to the outflow of air.

[0014] The invention has the advantages of simple structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com