Dynamic coupling device cooling and lubricating system of hybrid electric vehicle

A technology of hybrid electric vehicles and power coupling, which is applied in transmission parts, gear lubrication/cooling, belts/chains/gears, etc., can solve problems such as large volume, high cost, complex system structure, etc., to ensure system stability and performance Excellent, the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

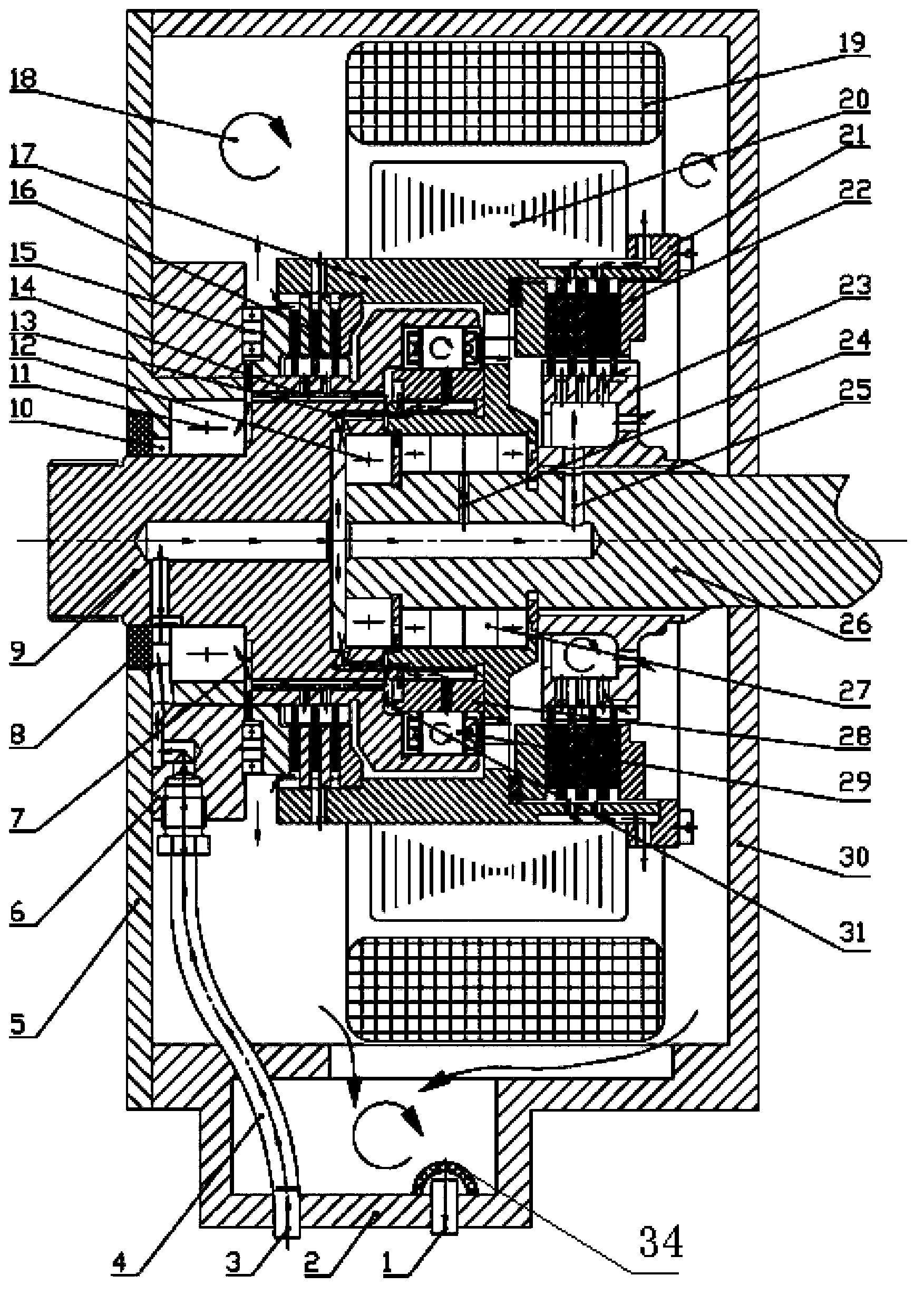

[0019] The present invention will be further described below in conjunction with the drawings.

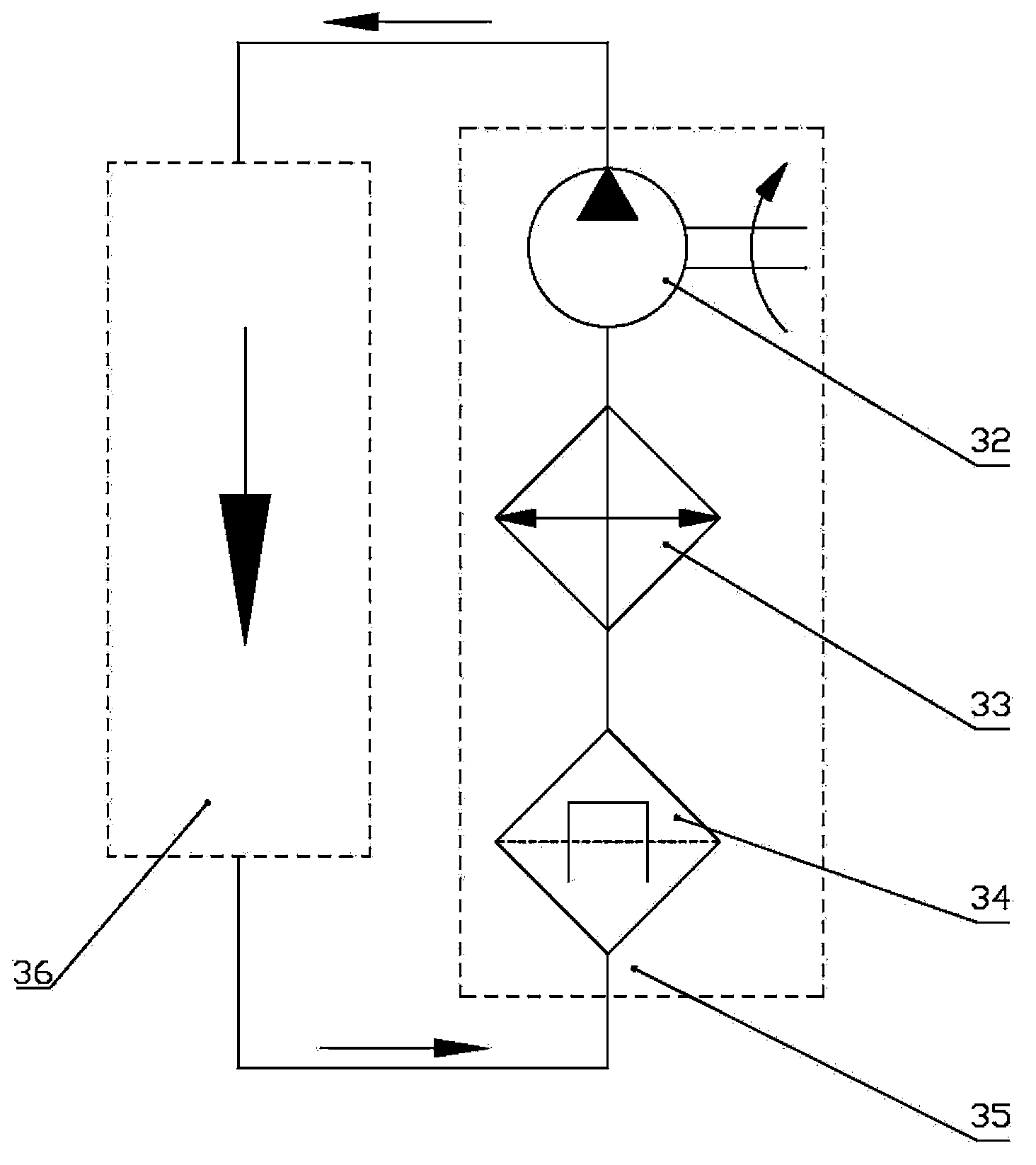

[0020] See figure 1 with figure 2 The power coupling device cooling and lubricating system of a hybrid vehicle shown is composed of the power coupling device external cooling circulation system 35 and the power coupling device housing internal cooling and lubricating circulation system 36;

[0021] The external cooling circulation system 35 of the power coupling device includes an oil sump 2 arranged at the lower part of the power coupling device housing, an oil inlet 3 and an oil outlet 1 arranged at the bottom of the oil sump, and an oil outlet 1 A filter 34 with a magnetic filter element, a radiator 33 whose inlet end is connected to the oil outlet, a power oil pump 32 whose one end is connected to the outlet end of the radiator, and the other end of the power oil pump is connected to one end of the oil pipe 4, which passes through The oil inlet 3 at the bottom of the oil pan 2 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com