Acidifying return stimulation experiment method

A simulation experiment and flowback technology, applied in the field of acidification flowback simulation experiment, can solve the problem of low foam stability, achieve the effect of simple steps and reduce simulation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The invention discloses an acidification flowback simulation experiment method, comprising the following steps:

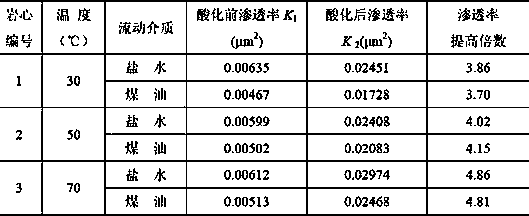

[0032] (a) First, measure the original permeability of the core;

[0033] (b) Press the flowback liquid into the core under the pressurized condition of the nitrogen cylinder until the flow rate of the solution flowing through the core is stable for a period of time;

[0034] (c) Then seal the end of the core holder and press a certain amount of hydrochloric acid into the core;

[0035] (d) Pressurized acidification, pressure relief, and spray acid solution from the positive end of the core holder;

[0036] (e) Measurement of core permeability after acidification.

[0037] In the step (b), the stabilization time is 3-5 minutes.

[0038] In the step (c), the mass fraction of hydrochloric acid is 15%.

[0039] In the step (d), the experimental temperature is kept at about 60°C.

[0040] In the step (d), the pressure is released after 30 minutes.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com