Device for detecting moisture content of lubricating oil and detection method thereof

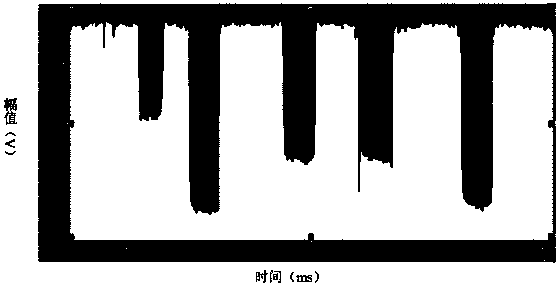

A detection device, lubricating oil technology, applied in the direction of measuring device, analyzing materials, material analysis by optical means, etc., to achieve the effect of improving detection sensitivity, reducing influence, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

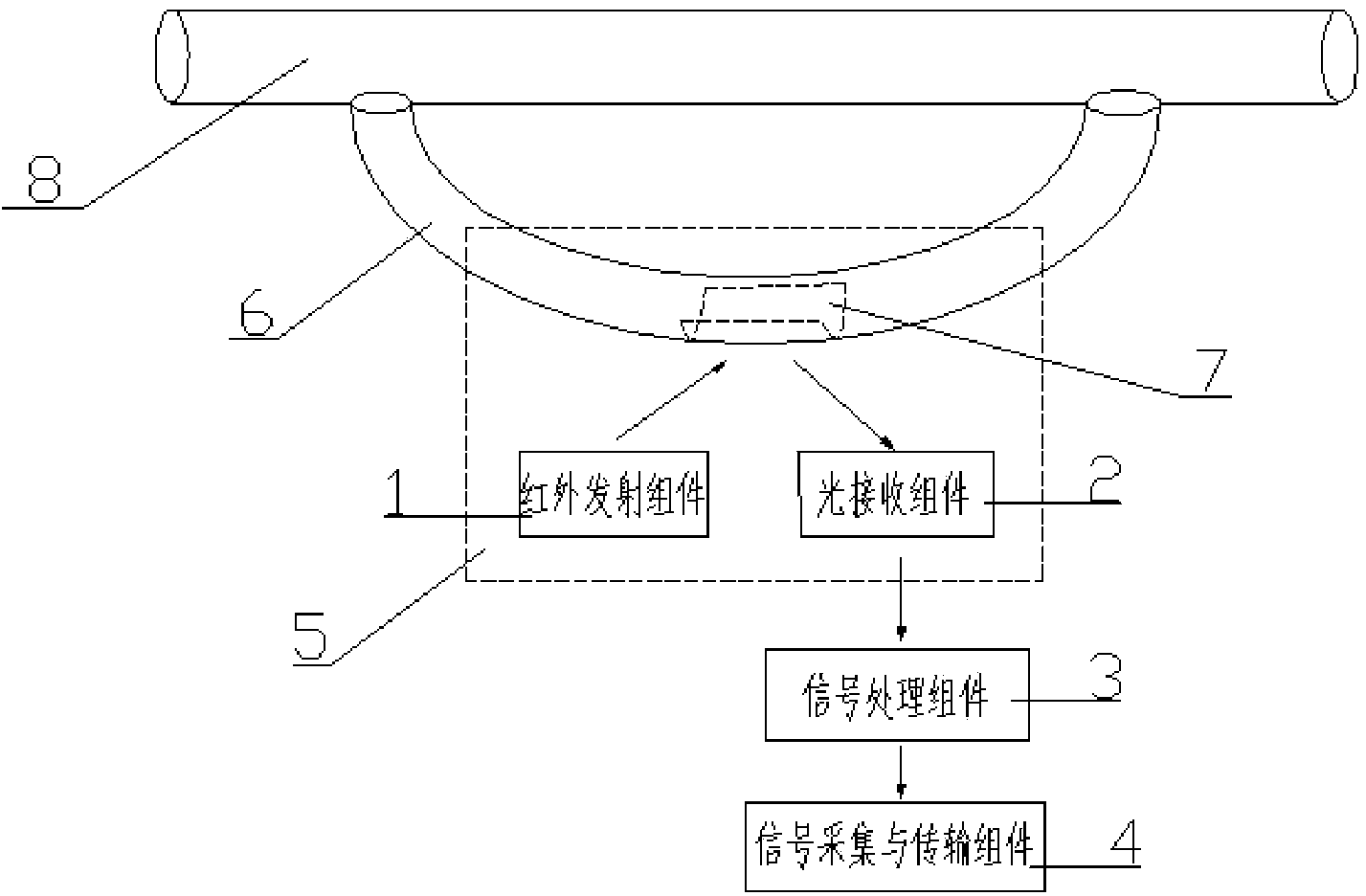

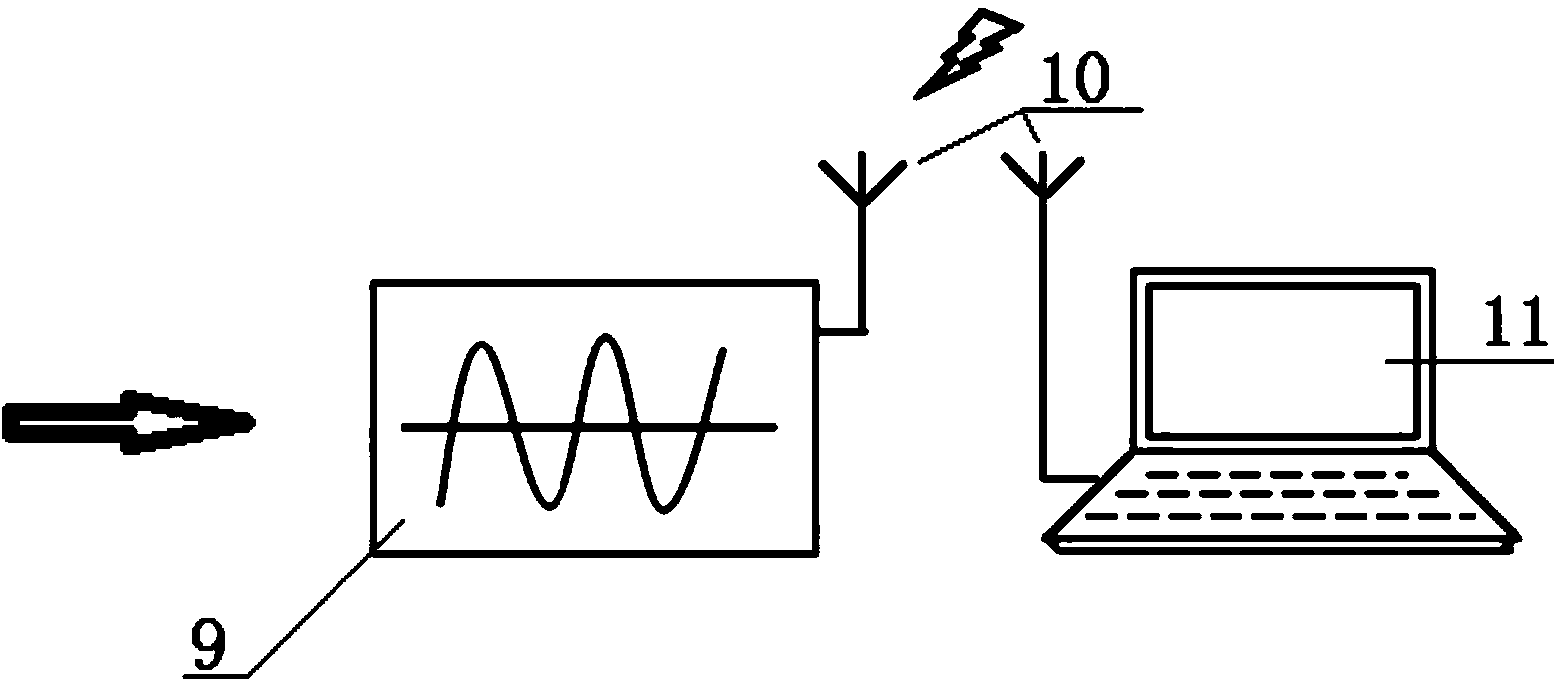

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Such as Figure 1-2 As shown, a detection device for moisture content in lubricating oil includes a platform 5, an infrared emitting component 1, a light receiving component 2, a signal processing component 3, a signal acquisition and transmission component 4 and an external oil pipeline 6, and the platform 5 is Darkroom structure, the infrared emitting assembly 1 and the light receiving assembly 2 are respectively fixed in the platform 5, the middle section of the external oil pipeline 6 is fixed in the platform 5, and its two ends are connected with the lubricating oil pipeline 8, and the light receiving assembly 2 is sequentially connected with the signal processing Component 3 and signal acquisition and transmission component 4 are connected in series;

[0034] The detection area at the bottom of the external oil pipeline 6 is coated with a super-hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com