Turboshaft engine dynamic real-time model establishing method and system

A turboshaft engine, model modeling technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as lack of component characteristic data, reduce labor intensity, reduce calculation time, and save design and development. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

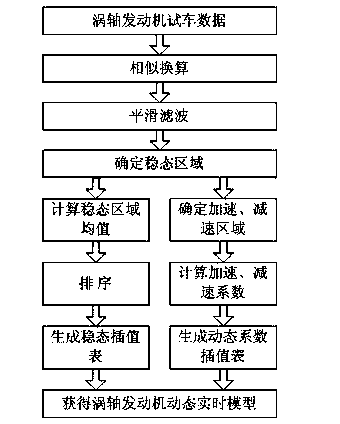

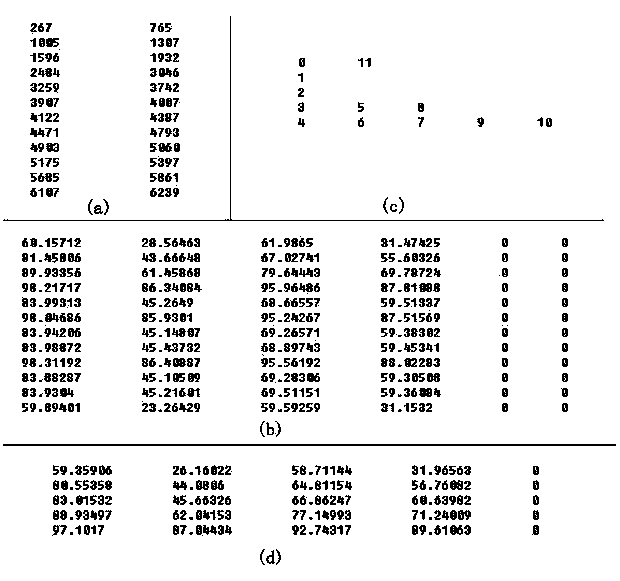

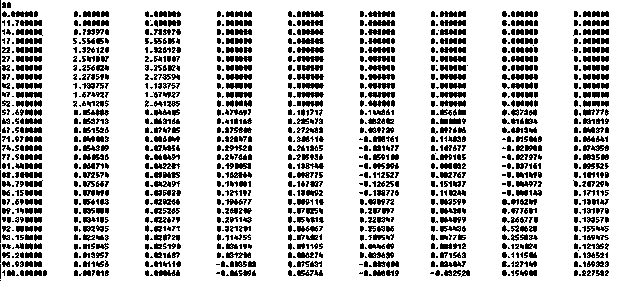

[0049] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0050] The idea of the present invention is to aim at the real-time model requirements of advanced turboshaft engines in the absence of component characteristic data, expand on the basis of the existing general model modeling method of aeroengines, and use the dynamic acceleration and deceleration coefficient method of the remaining fuel flow to establish The dynamic real-time model of the turboshaft engine, including the start-up model, the gas generator model above the idle state, and the power turbine and load model, compared with the nonlinear component-level model, the calculation time consumption of the model is significantly reduced, and it can meet the airborne real-time performance Requirements, suitable for the lack of component characteristics and only based on test data modeling, and the designed engine dynamic real-time model automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com