Ternary cathode material with special single crystal structure and preparation method thereof

A single crystal structure, positive electrode material technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of secondary balls being easily broken and low compaction, so as to achieve not easy to break, reduce polarization loss, and not easy The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

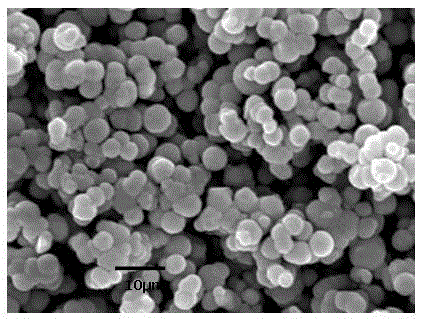

[0021] The single crystal structure ternary cathode material LiNi was prepared according to the following steps 0.25 co 0.25 mn 0.5 f 0.01 o 2

[0022] 1) Accurately weigh 200 grams of nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio of Ni:Co:Mn=1:1:2, dissolve them in a certain amount of water, prepare the solution, and then slowly add ammonia water dropwise into the solution, When the pH is 9, pour the solution into the reaction kettle, put the reaction kettle into a muffle furnace for sintering at 385°C for 17 hours, cool, wash, dry and grind to obtain a single crystal structure precursor, that is, nickel cobalt manganese oxide.

[0023] 2) According to the molar ratio of Li to the sum of nickel, cobalt, and manganese of 1.01:1, weigh lithium carbonate, and the ratio of F to the sum of nickel, cobalt, and manganese is 0.01:1 to weigh lithium fluoride, and lithium carbonate, Mix nickel-cobalt-manganese oxide and lithium fluoride evenly,...

Embodiment 2

[0026] The single crystal structure ternary cathode material LiNi was prepared according to the following steps 0.25 co 0.25 mn 0.5 Cr 0.02 o 2

[0027] 1) Accurately weigh 200 grams of nickel nitrate, cobalt nitrate, and manganese nitrate according to the molar ratio of Ni:Co:Mn=1:1:2, dissolve them in a certain amount of water, prepare the solution, and then slowly add ammonia water dropwise into the solution, When the pH is 9, pour the solution into the reaction kettle, put the reaction kettle into a muffle furnace for sintering at 420°C for 15 hours, cool, wash, dry, and grind to obtain a single crystal structure precursor, that is, nickel cobalt manganese oxide.

[0028] 2) According to the molar ratio of Li to the sum of nickel, cobalt, and manganese of 1.02:1, weigh lithium carbonate, and the ratio of Cr to the sum of nickel, cobalt, and manganese is 0.02:1 to weigh lithium fluoride, and lithium carbonate, Mix nickel-cobalt-manganese oxide and chromium nitrate even...

Embodiment 3

[0031] The single crystal structure ternary cathode material LiNi was prepared according to the following steps 0.25 co 0.25 mn 0.5 Ti 0.02 o 2

[0032] 1) According to the molar ratio of Ni:Co:Mn=1:1:2, accurately weigh 200 grams of nickel chloride, cobalt chloride, and manganese chloride and dissolve them in a certain amount of water to prepare the solution, and then slowly add ammonia water dropwise to solution, until the pH is 9, pour the solution into a reaction kettle, put the reaction kettle into a muffle furnace for sintering at 350°C for 17 hours, cool, wash, dry, and grind to obtain a single crystal structure precursor, namely nickel cobalt manganese oxide.

[0033] 2) According to the molar ratio of Li to the sum of nickel, cobalt, and manganese of 1.02:1, weigh lithium hydroxide, and the ratio of Cr to the sum of nickel, cobalt, and manganese is 0.02:1 to weigh lithium fluoride, and lithium carbonate , nickel-cobalt-manganese oxide and chromium nitrate are ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com