Moving magnet type linear oscillation motor without inner stator

A technology of oscillating motors and inner stators, which is applied in the direction of electrical components and electromechanical devices, can solve the problems of complex structural iron core lamination, difficulty in stacking inner stators, and large volume of the whole machine, achieving compact structure, low cost, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

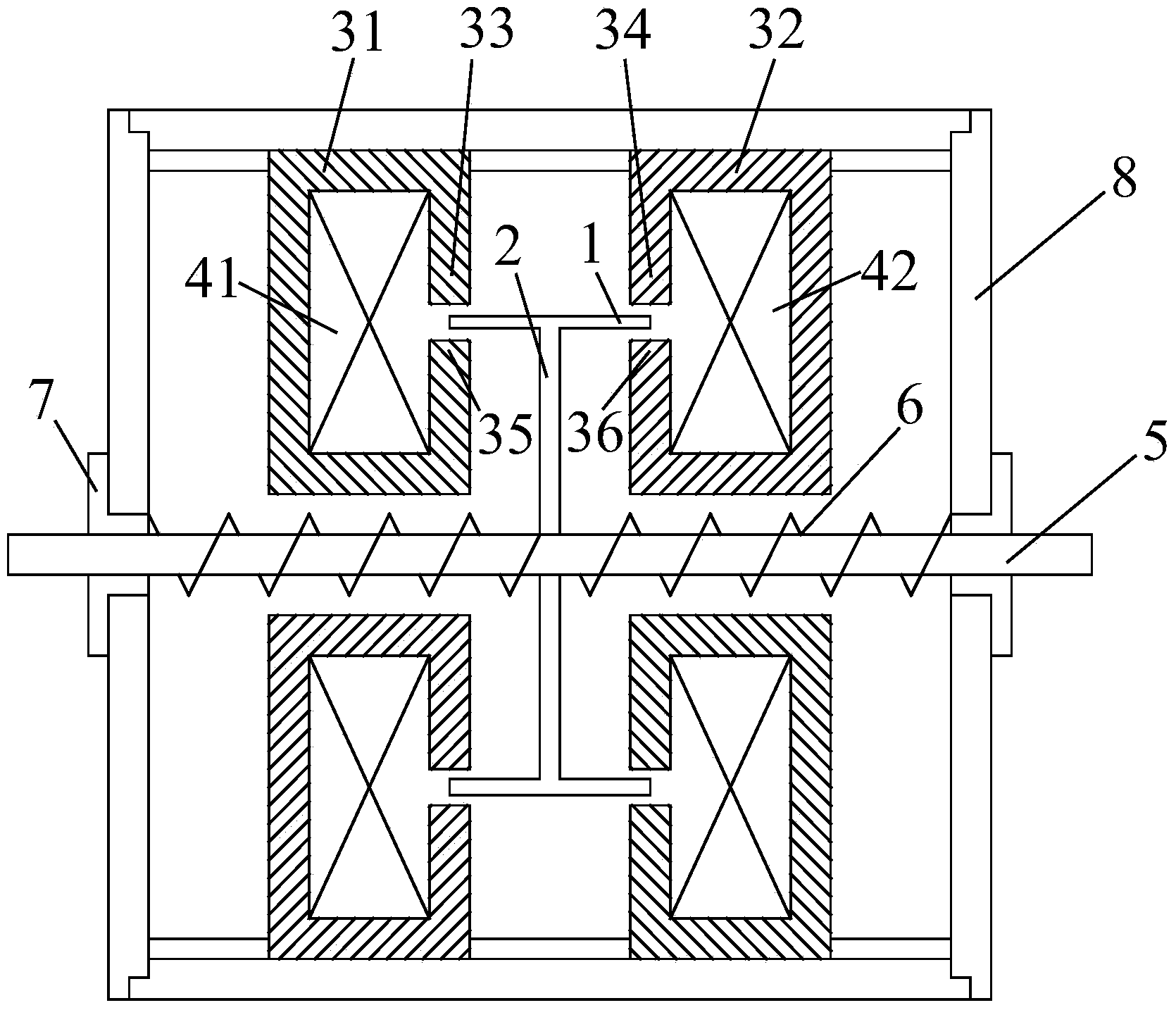

[0028] Embodiment 1, Figure 1 to Figure 7 Provided is a moving magnet type linear oscillation motor without inner stator; it includes a casing 8 in which a stator and a mover are arranged.

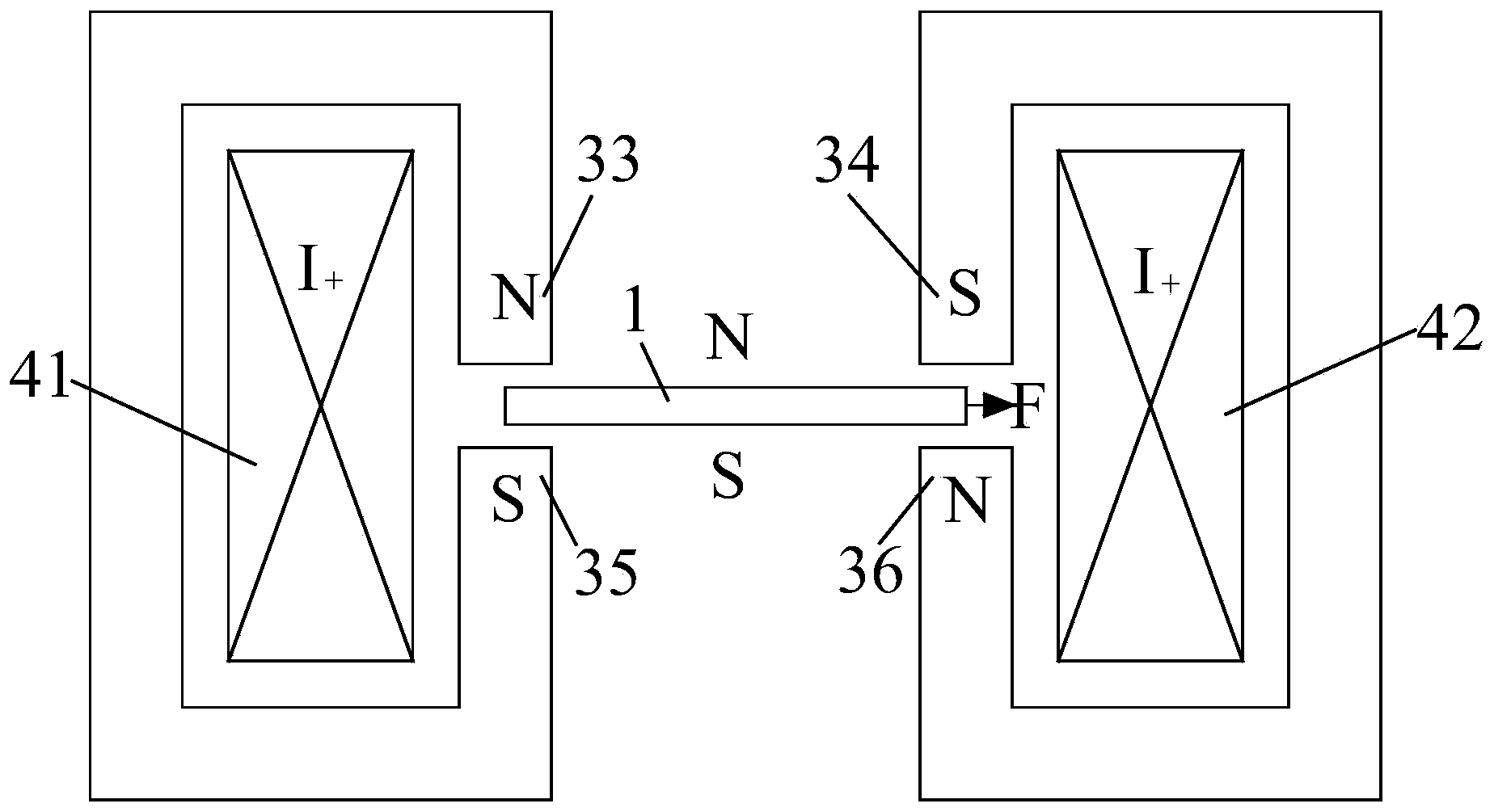

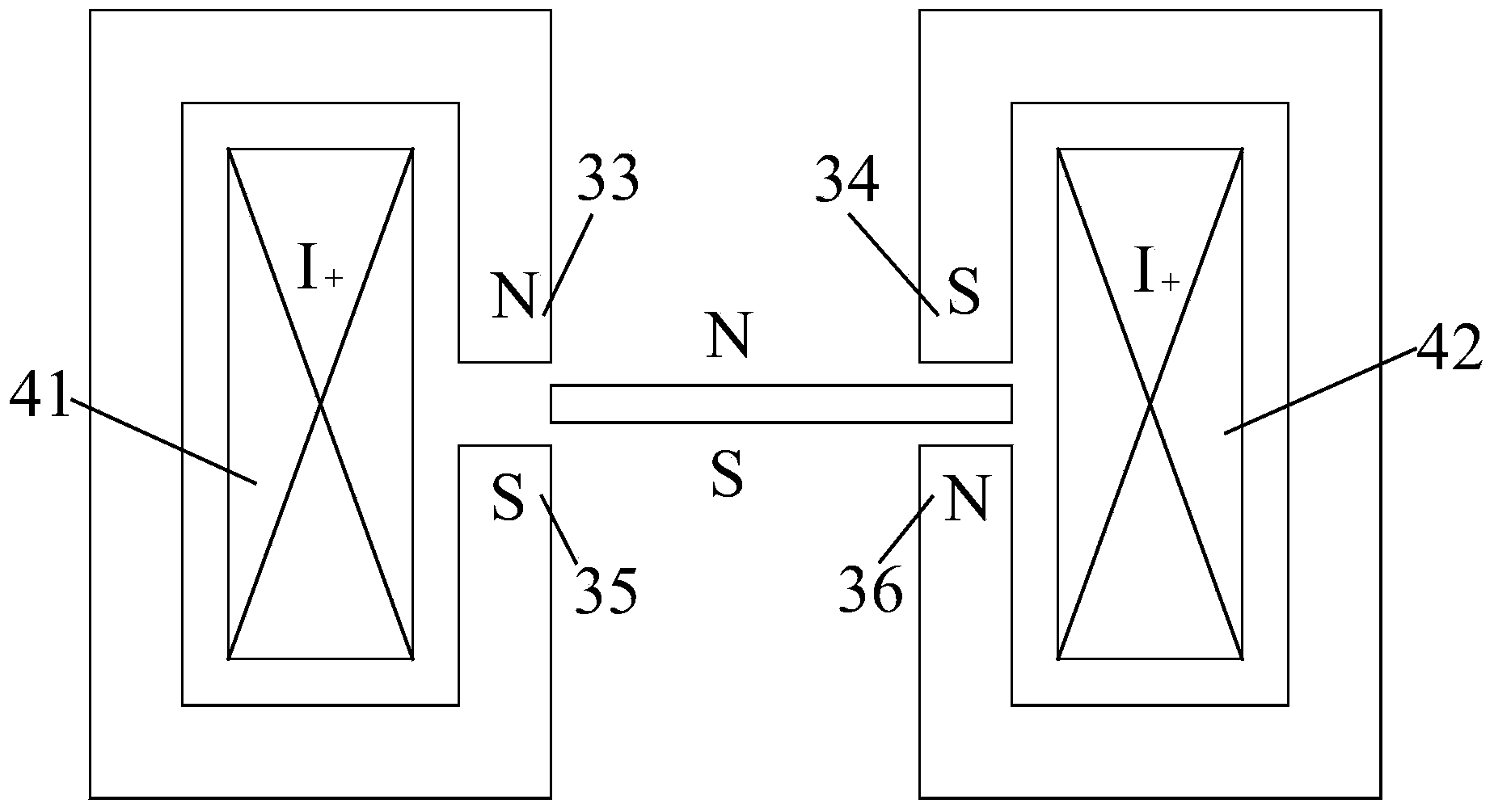

[0029] The stator is composed of a stator core, an armature winding and an annular winding support; the stator core is divided into a left stator core 31 and a right stator core 32 which are arranged symmetrically; the left stator core 31 and the right stator core The cores 32 are all "C" type stator cores, and the gap of the left stator core 31 is facing the gap of the right stator core 32; A number of small stator core blocks are assembled; the left armature winding 41 is arranged on the left annular winding support; the right stator core 32 is made of a hard plastic processed right annular winding The core blocks are assembled; the right armature winding 42 is set on the right annular winding support (the left armature winding 41 and the right armature winding 42 are arranged in oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com