Method for regulating and controlling tobacco shred quality uniformity of different batches of cigarettes and application of method

A uniformity and cigarette technology is applied in the field of regulation to control the quality uniformity of cigarette cut tobacco in different batches. The effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

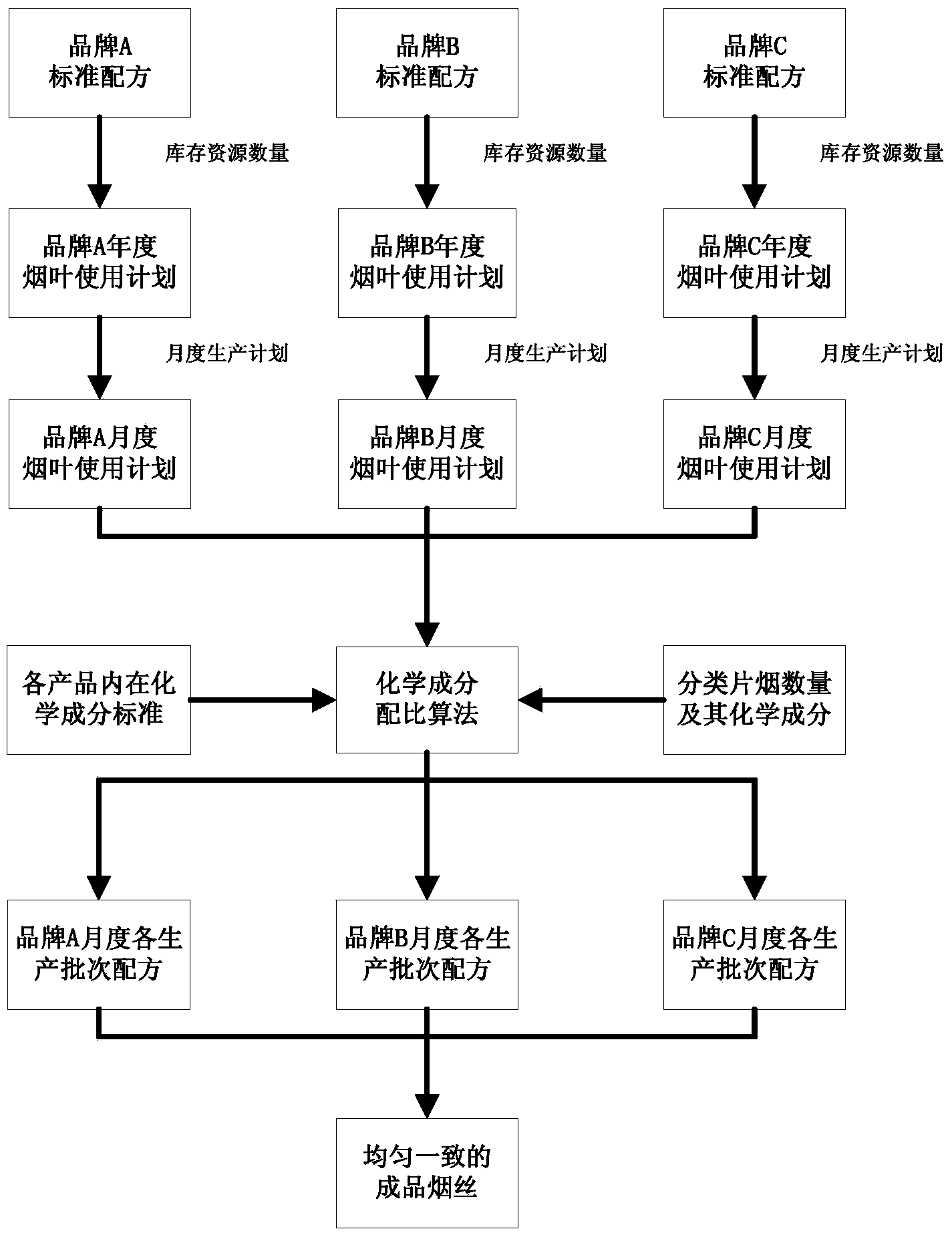

[0039] The finished sheet tobacco a of a certain grade used in the brand A formula consists of a total of 100,000 palons of raw tobacco, and the finished sheet tobacco produced after threshing and redrying totals 65,000 palons.

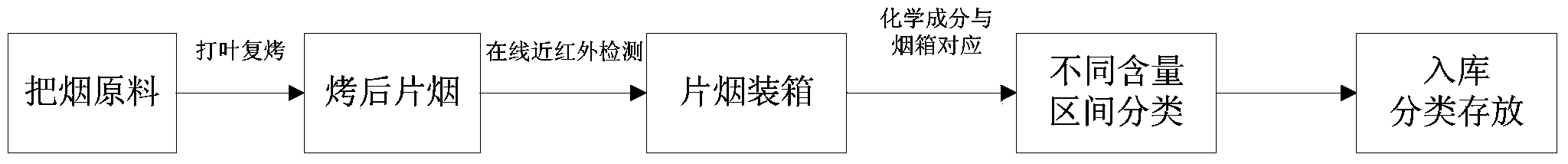

[0040] 1) Detection of the chemical composition of the finished tobacco after threshing and redrying: An online near-infrared spectroscopy instrument is installed at the exit of the redrying machine to continuously detect 65,000 tons of finished tobacco from the redrying machine and continuously obtain it on the assembly line The chemical value of the chemical composition of the finished cigarette for 30 seconds; the chemical value is recorded in the online near-infrared spectrometer software;

[0041] 2) The chemical composition corresponds to the data of the finished piece of cigarettes after packing: the finished piece of cigarettes after testing is packed, and when each cigarette box reaches the set weight of the electronic scale, the electronic scale w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com