Multi-layer cover plate for drilling

A multi-layer and cover plate technology, which is applied in the direction of drilling/drilling equipment, layered products, metal layered products, etc., can solve the problems of high hardness of aluminum substrates, drill pin slippage, hole offset, etc., and achieve improved Thermal conductivity, avoiding needle entanglement, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

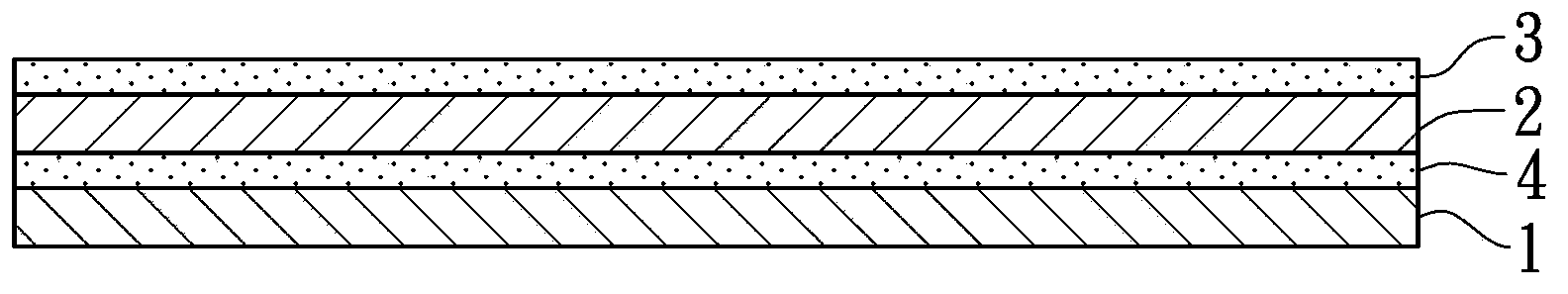

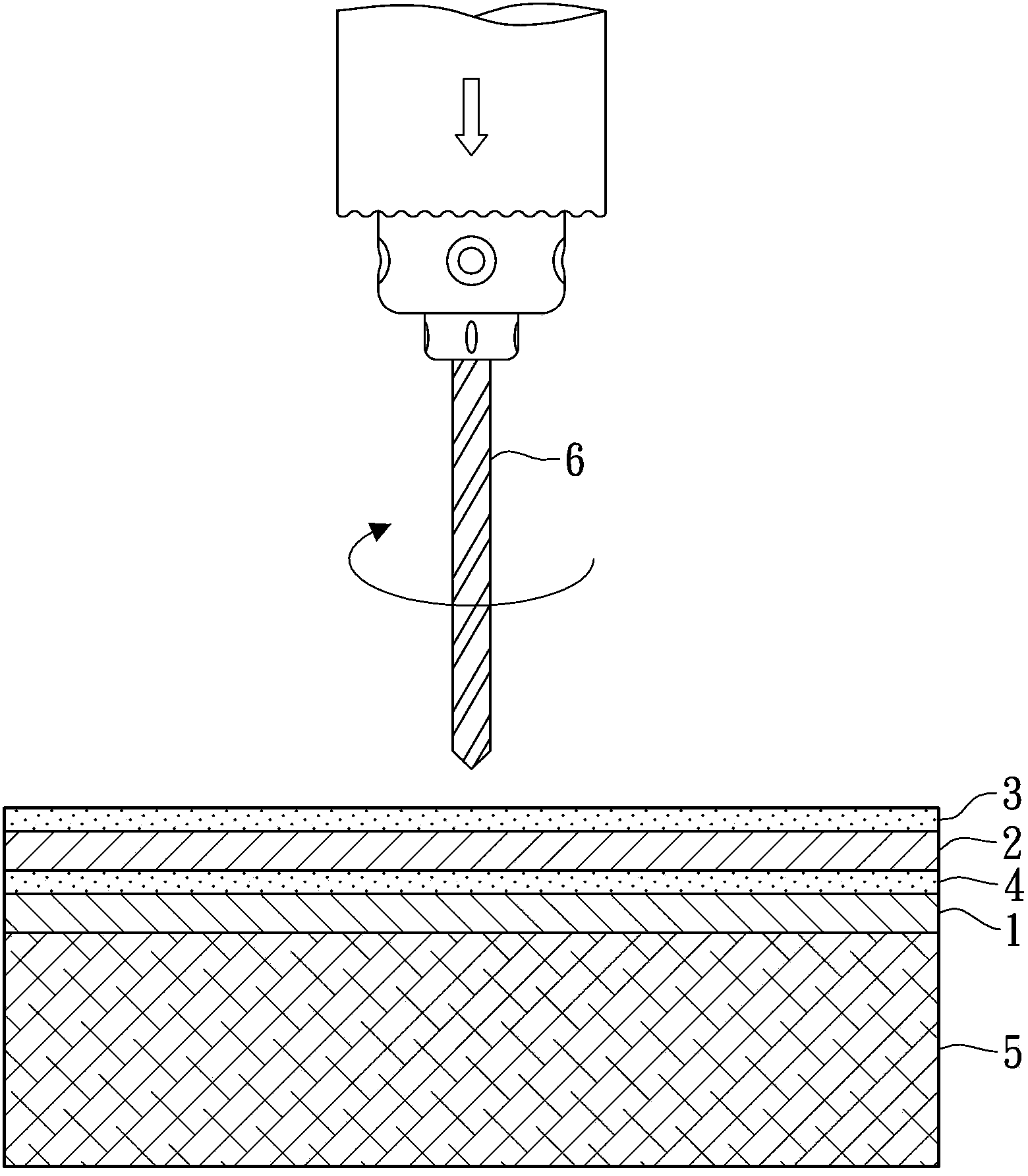

[0026] see figure 1 , figure 2 , the content of the accompanying drawing is an embodiment of the present invention, which is composed of an aluminum bottom layer 1, an aluminum middle layer 2, a first adhesive layer 3 and a second adhesive layer 4, so that it is arranged on a printed circuit After the board 5 is on, provide the drilling needle 6 to carry out the drilling operation.

[0027] The first adhesive layer 3 is arranged on the aluminum middle layer 2, the second adhesive layer 4 is arranged between the aluminum bottom layer 1 and the aluminum middle layer 2, and the first adhesive layer 3 is lubricating resin, bonding resin It is mixed with high thermal conductivity compound, wherein the lubricating resin accounts for 40%~60% by weight, the combined resin accounts for 20~30% by weight, and the high thermal conductivity compound accounts for 40~10% by weight. The second adhesive layer 4 is formed by mixing a bonding resin and a high thermal conductivity compound. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com