Reverse boring processing cutter device and use method thereof for hard sealing hole end surface

A hole end face and countersinking technology is applied in the field of reverse countersinking machining tool devices for hard sealing hole end faces. Efficiency, the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

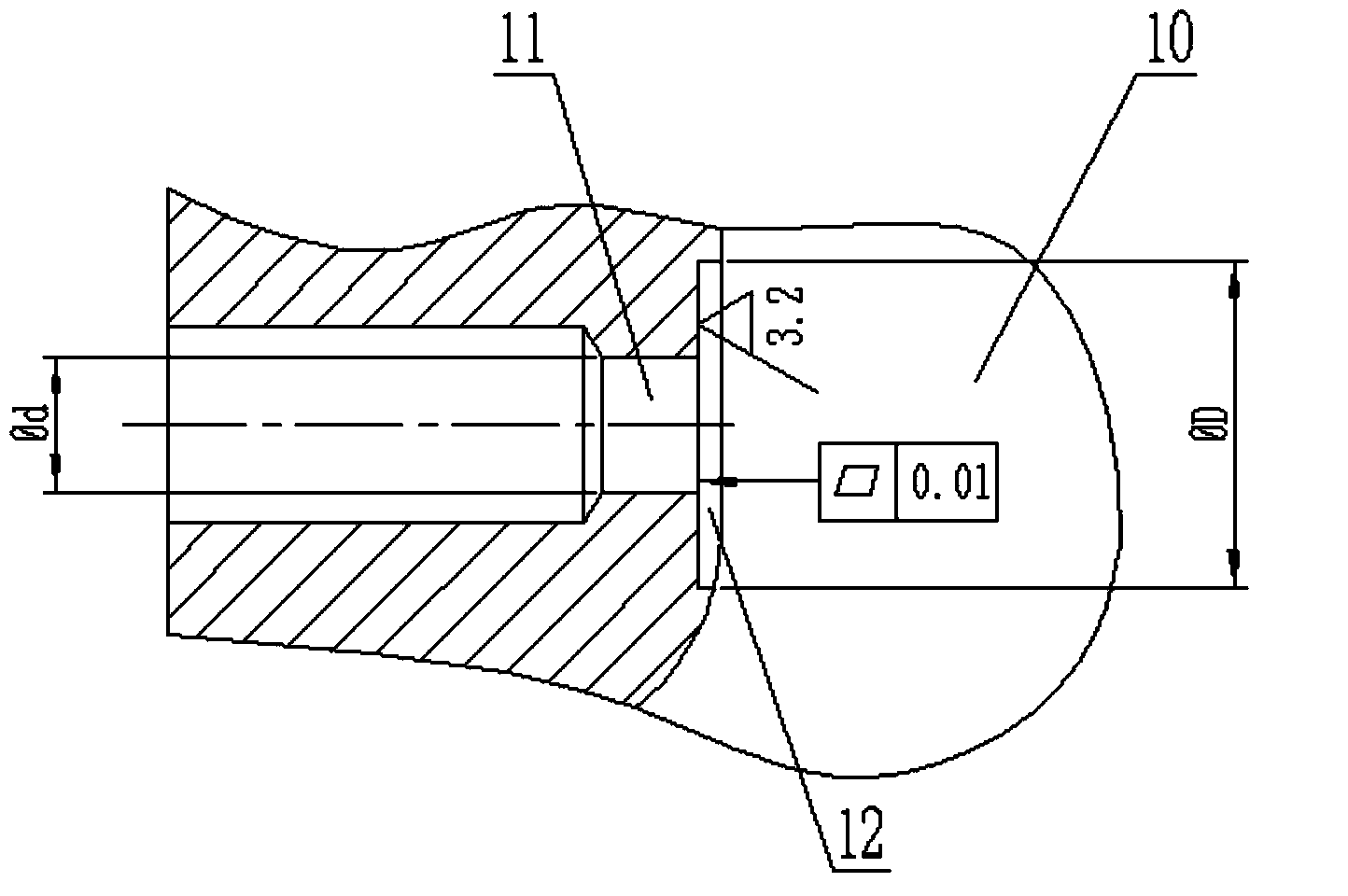

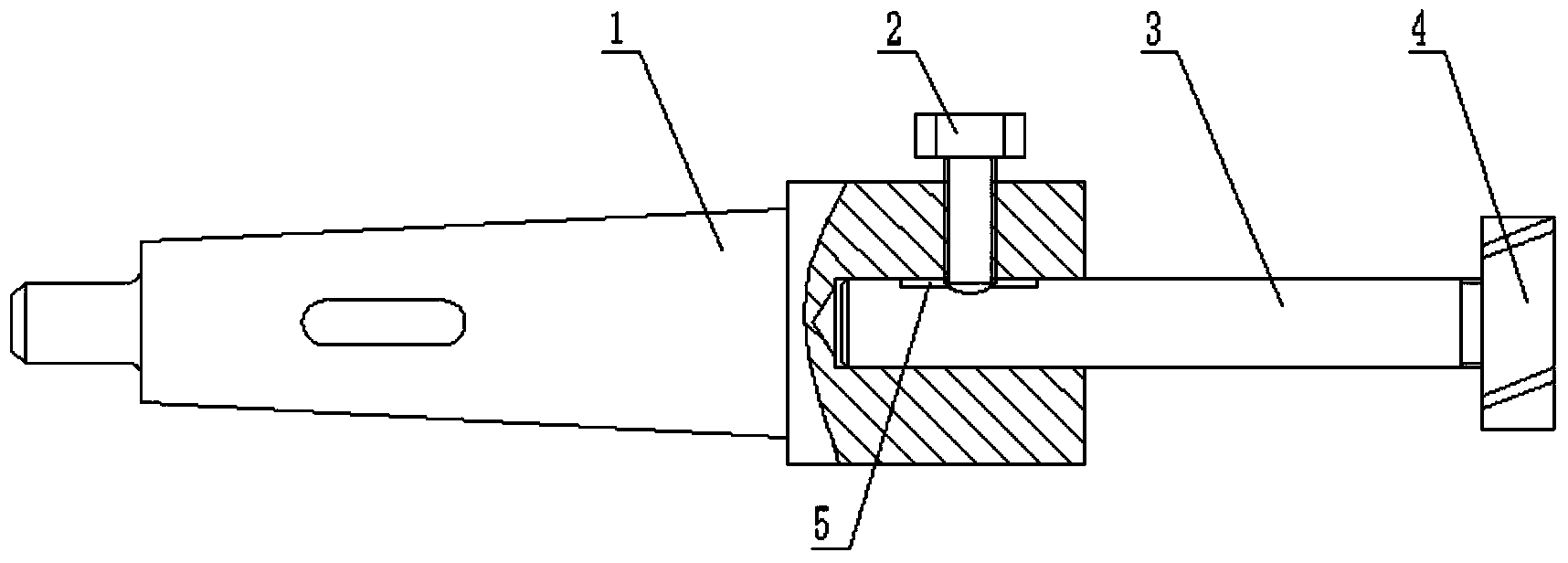

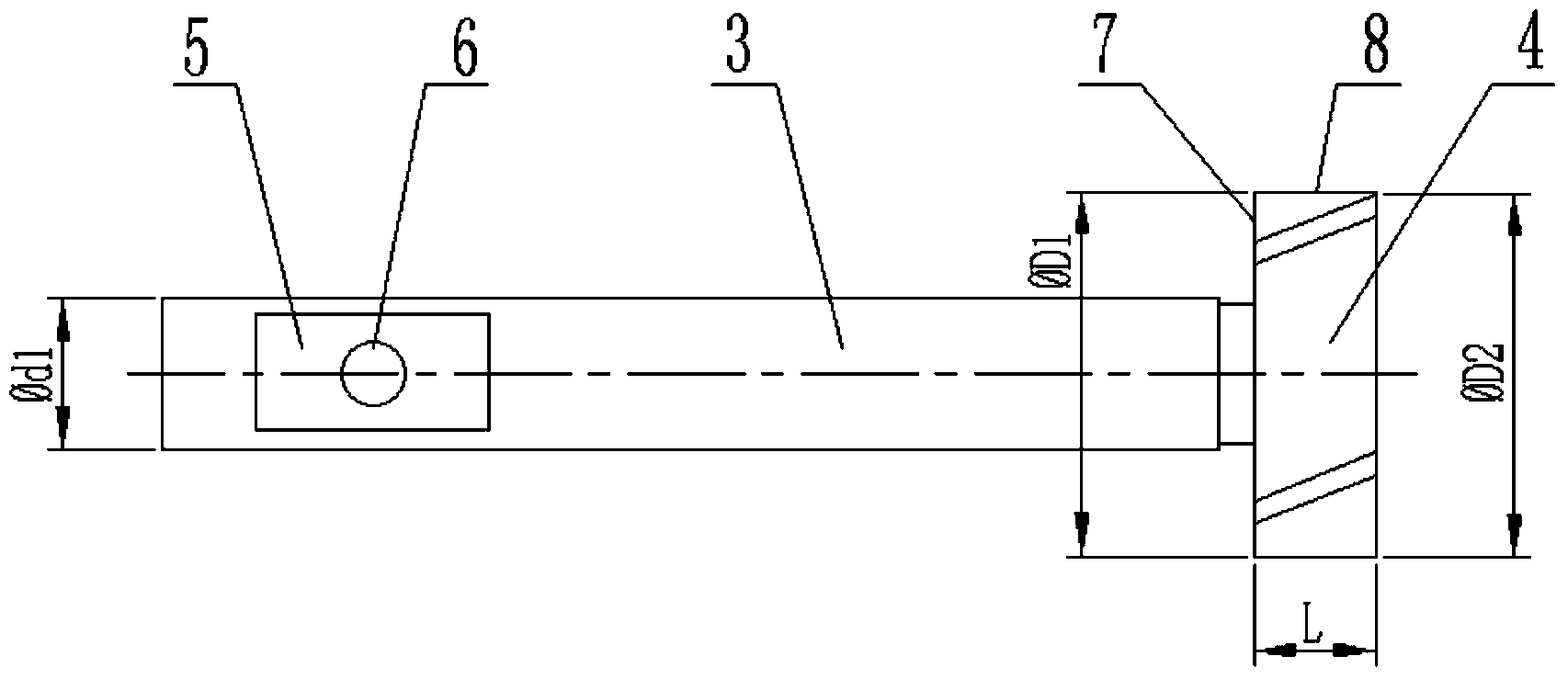

[0036] Embodiment 1: select thickness L to be 8mm, the knife tip outer diameter φ D1 of main cutting edge 7 is smaller than the maximum size of counterbore 12 internal diameter φ D on workpiece 10 smaller 0.05mm cutter head, first Morse tool holder 1 is packed Clamp it on the spindle of the machine tool, loosen the compression nut 2, and then pass the tool bar 3 of the integral countersinking tool through the positioning hole 11 on the workpiece 10, and insert it into the tool installation hole 13 opened in the middle of the Morse tool holder 1 Inside, in order to facilitate the sliding adjustment of the tool bar 3 in the positioning hole 11 and the tool mounting hole 13, the diameter φd1 of the tool bar 3 is 0.05mm smaller than the internal diameter φd of the positioning hole 11 on the workpiece 10, and smaller than the internal diameter φd2 of the tool mounting hole 13 0.005mm; Rotate and move the integral countersinking tool back and forth, so that the rectangular groove 5 o...

Embodiment 2

[0037]Embodiment 2: select thickness L to be 13mm for use, the knife tip outer diameter φ D1 of main cutting edge 7 is smaller than the maximum size of the counterbore 12 internal diameter φ D of workpiece 10 the cutter head of 0.06mm, earlier Morse tool holder 1 is packed Clamp it on the spindle of the machine tool, loosen the compression nut 2, and then pass the tool bar 3 of the integral countersinking tool through the positioning hole 11 on the workpiece 10, and insert it into the tool installation hole 13 opened in the middle of the Morse tool holder 1 Inside, in order to facilitate the sliding adjustment of the tool bar 3 in the positioning hole 11 and the tool mounting hole 13, the diameter φd1 of the tool bar 3 is 0.08mm smaller than the internal diameter φd of the positioning hole 11 on the workpiece 10, and smaller than the internal diameter φd2 of the tool mounting hole 13 0.008mm; Rotate and move the integral countersinking tool back and forth, so that the rectangul...

Embodiment 3

[0038] Embodiment 3: select thickness L to be 20mm for use, the knife tip outer diameter φ D1 of main cutting edge 7 is smaller than the maximum size of counterbore 12 internal diameter φ D on workpiece 10 smaller 0.1mm cutter head, first Morse tool holder 1 is packed Clamp it on the spindle of the machine tool, loosen the compression nut 2, and then pass the tool bar 3 of the integral countersinking tool through the positioning hole 11 on the workpiece 10, and insert it into the tool installation hole 13 opened in the middle of the Morse tool holder 1 Inside, in order to facilitate the sliding adjustment of the tool bar 3 in the positioning hole 11 and the tool mounting hole 13, the diameter φd1 of the tool bar 3 is 0.1mm smaller than the internal diameter φd of the positioning hole 11 on the workpiece 10, and smaller than the internal diameter φd2 of the tool mounting hole 13 0.01mm; Rotate and move the integral countersinking tool back and forth, so that the rectangular groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com