Device for tightening and assembling circular nut on output shaft of planetary gearbox and testing torque

A detection device and output shaft technology, applied in the direction of measuring devices, torque measurement, instruments, etc., can solve the problems of difficult detection of production standards, damage to large nut installation, and large waste of manpower, so as to shorten the production and processing time and shorten the processing time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

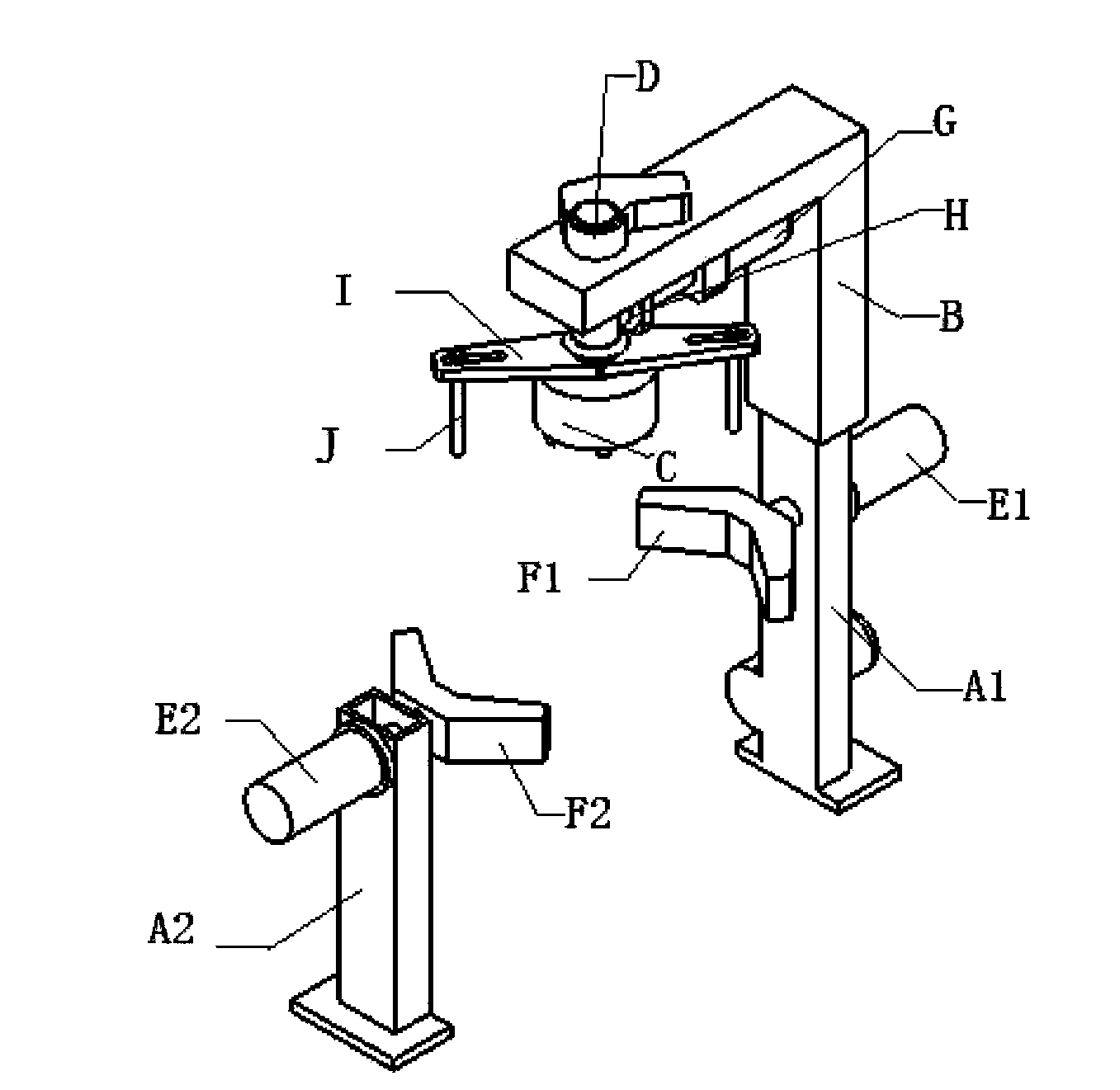

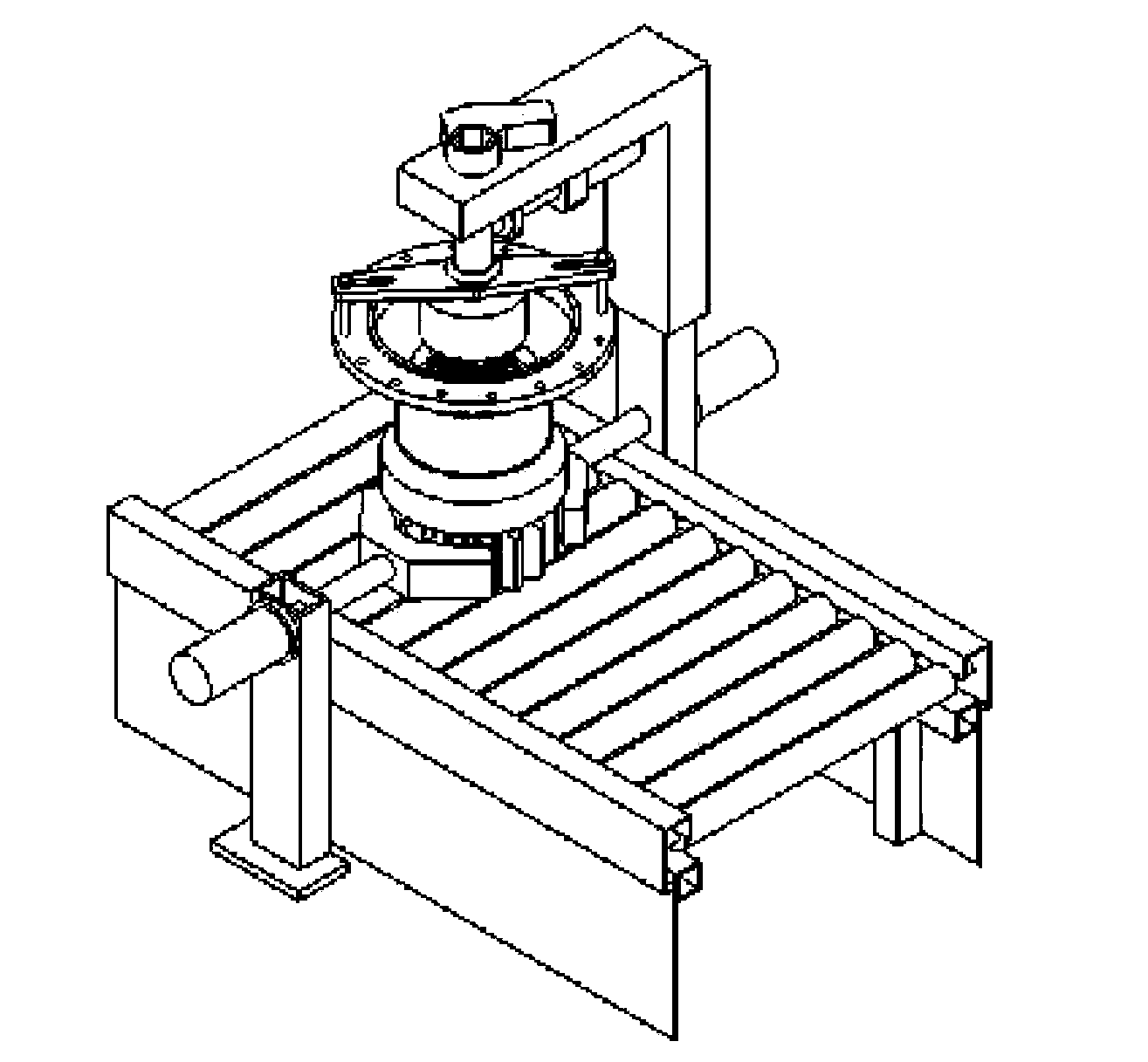

[0018] to combine figure 1 , The composition of the round nut tightening assembly and torque detection device includes: wrench frame column A, wrench frame B, round nut torque wrench C, hydraulic wrench D, turning machine cylinder E, turning machine fixture F, reducer Torque sensor G, bevel gear H, lever fixing frame I, lever J.

[0019] The torque detection device composed of the wrench fixing frame (I), the wrench (J), the bevel gear (H) and the reducer torque sensor (G) and the nut composed of the round nut torque wrench (C) and the hydraulic wrench (D) The two parts of the installation and fastening device are installed on the wrench frame (B), and the mold turning machine composed of the turning machine cylinder (E) and the turning machine fixture (F) is installed on the wrench frame (A), and the wrench frame (B) Installed on the wrench frame post (A).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com