1.4435 stainless steel injection molded feedstock and preparation method thereof

An injection molding, stainless steel technology, applied in the field of powder metallurgy, can solve problems affecting product consistency, production processing time, and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

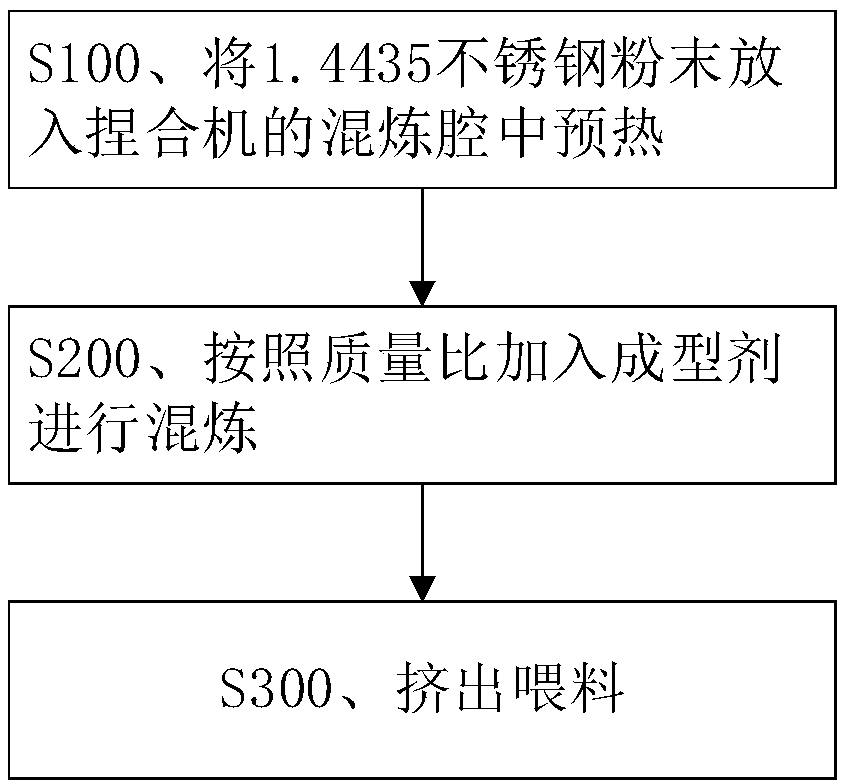

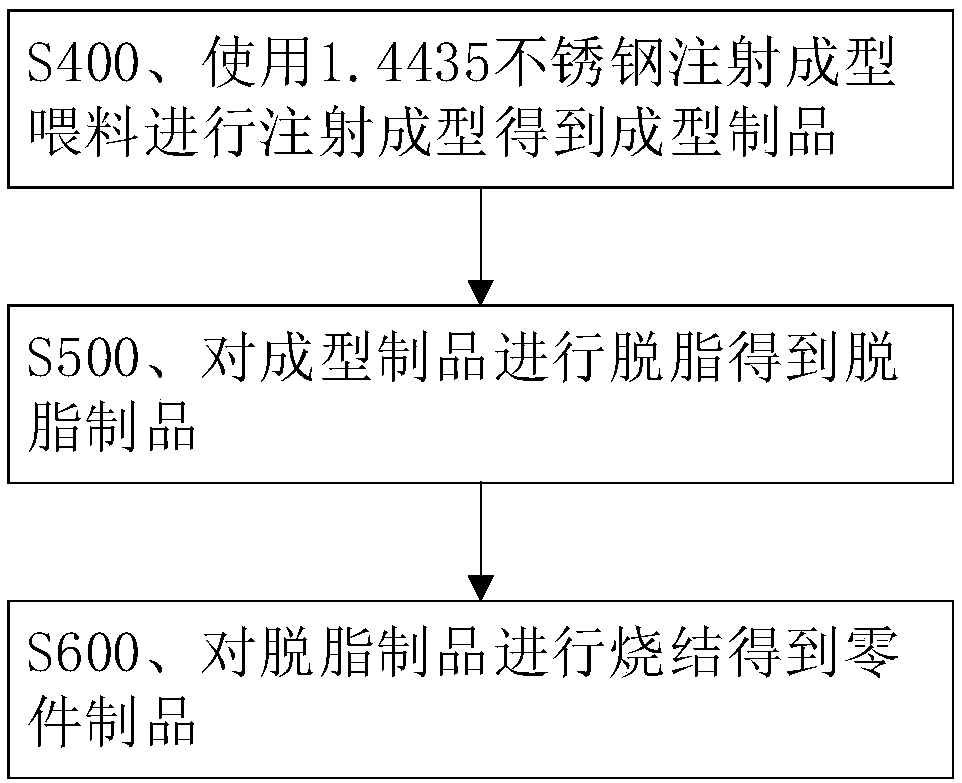

Method used

Image

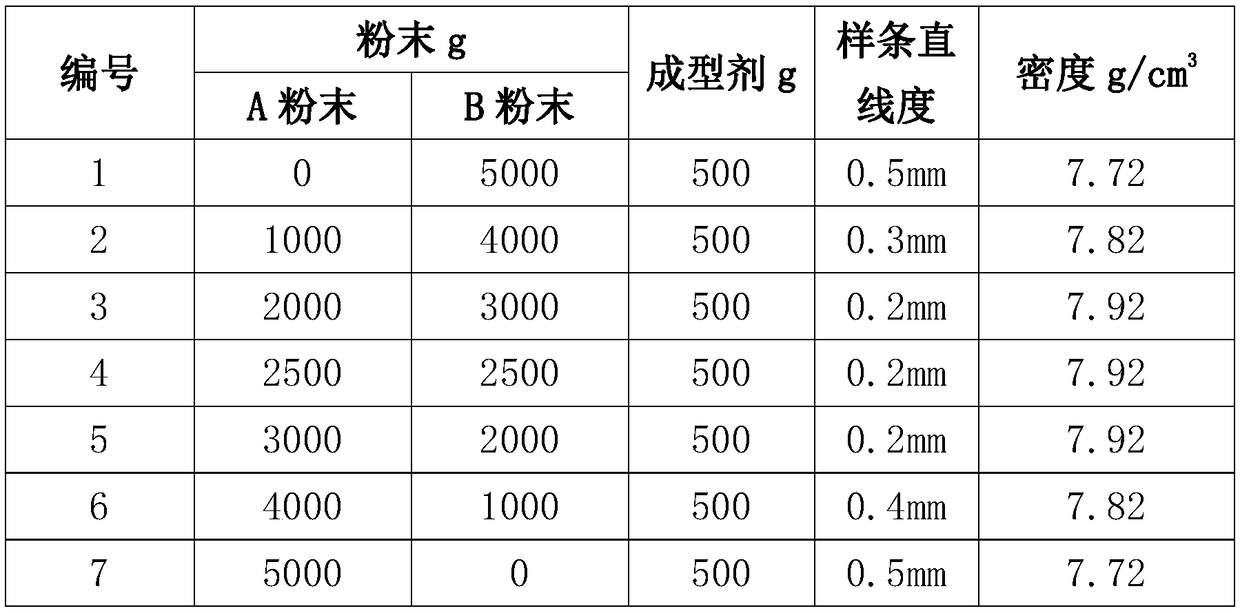

Examples

Embodiment 1

[0055] Put 5 kg of 1.4435 stainless steel powder into the mixing chamber of the kneader and preheat it to 180°C-190°C. The specification of the 1.4435 stainless steel powder is 9 microns, and start the kneader to rotate slowly from 4r / min to 6r / min. After the temperature of 1.4435 stainless steel powder is ≥170°C, add 0.5 kg of molding agent (the mass ratio of 1.4435 stainless steel powder to molding agent is about 91:9): 40 grams (8%) of white beeswax, 15 grams of zinc stearate (3 %), 30 grams (6%) of high-density polyethylene, 20 grams (4%) of polypropylene wax, 30 grams (6%) of ethylene-vinyl acetate copolymer, 365 grams (73%) of polyformaldehyde.

Embodiment 2

[0057] Put 4.6 kg of 1.4435 stainless steel powder into the mixing chamber of the kneader and preheat it to 180°C-190°C. The specification of the 1.4435 stainless steel powder is 9 microns. Start the kneader and rotate slowly from 4r / min to 6r / min. After the temperature of 1.4435 stainless steel powder is ≥170°C, add 0.4 kg of molding agent (the mass ratio of 1.4435 stainless steel powder to molding agent is about 92:8): 32 grams (8%) of white beeswax, 12 grams of zinc stearate (3 %), 24 grams (6%) of high-density polyethylene, 16 grams (4%) of polypropylene wax, 24 grams (6%) of ethylene-vinyl acetate copolymer, 292 grams (73%) of polyformaldehyde.

Embodiment 3

[0059] Put 4.6 kg of 1.4435 stainless steel powder into the mixing chamber of the kneader and preheat it to 180°C-190°C. The specification of the 1.4435 stainless steel powder is 9 microns. Start the kneader and rotate slowly from 4r / min to 6r / min. After the temperature of 1.4435 stainless steel powder is ≥170°C, add 0.4 kg of molding agent (the mass ratio of 1.4435 stainless steel powder to molding agent is 92:8): 28 grams (7%) of white beeswax, 8 grams (2% of zinc stearate) ), 20 grams (5%) of high-density polyethylene, 20 grams (5%) of polypropylene wax, 28 grams (7%) of ethylene-vinyl acetate copolymer, 296 grams (74%) of polyoxymethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com