Solar photovoltaic cell production and processing equipment

A technology for photovoltaic cells and processing equipment, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems such as poor frame bonding effect, low processing efficiency, and affecting the production and processing efficiency of solar photovoltaic cells, and achieve production High efficiency, improved installation effect, and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

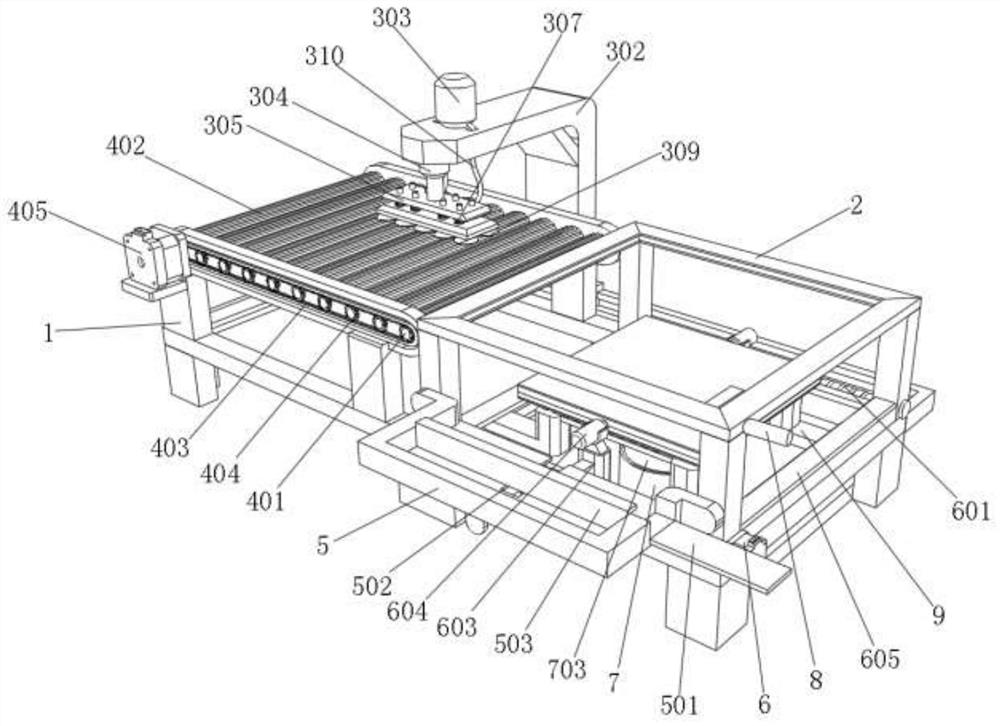

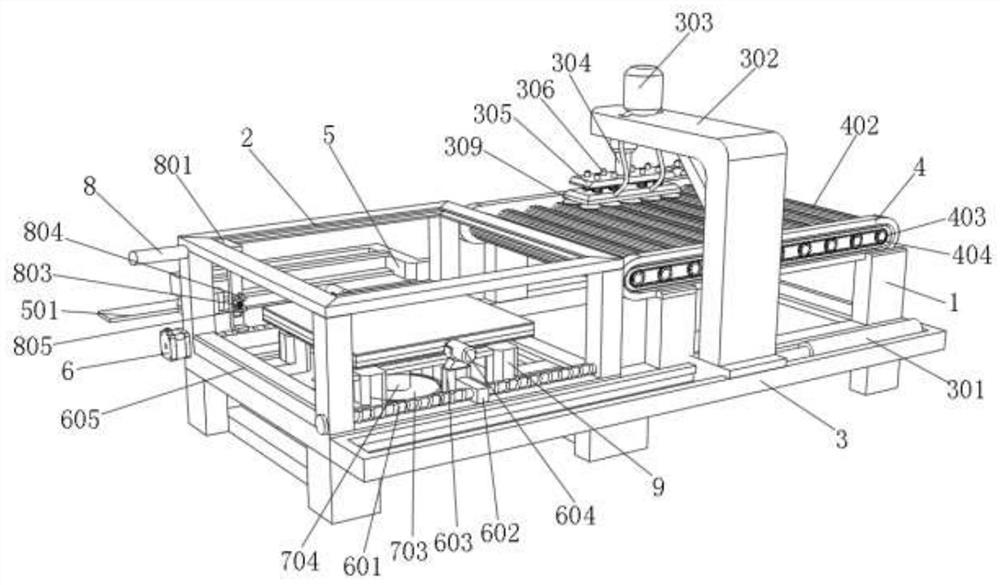

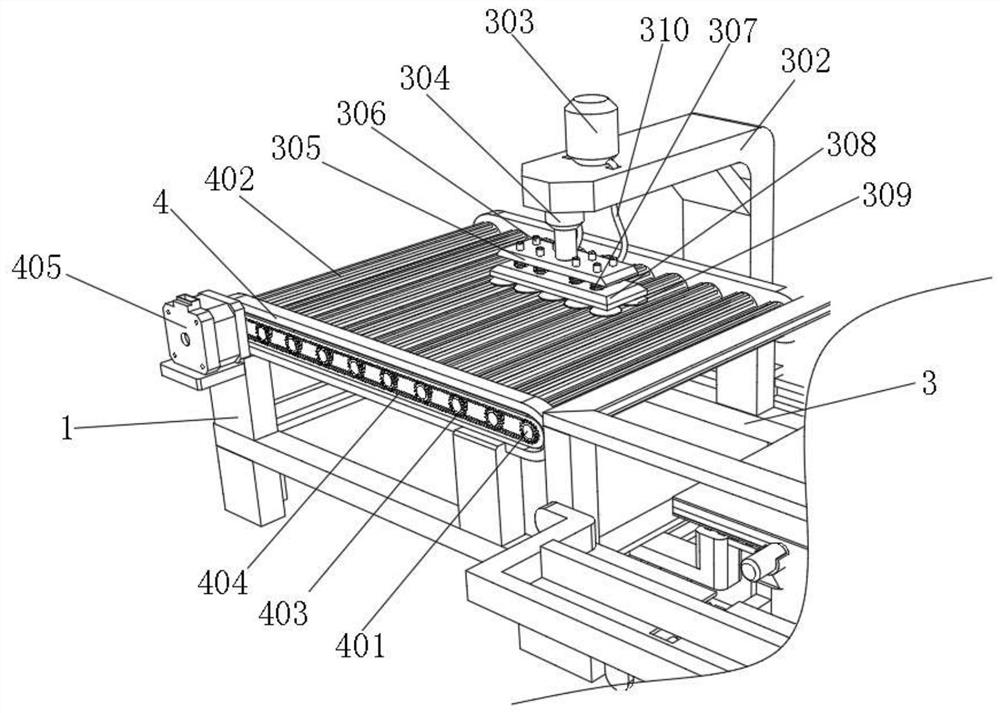

[0032] refer to Figure 1-Figure 4, a solar photovoltaic cell production and processing equipment, including a support frame 1 and an installation frame 2, one side of the support frame 1 and one side of the installation frame 2 are fixedly connected by bolts, and one side of the support frame 1 and the installation frame 2 is fixed with a slideway by bolts 3. One side of the slideway 3 is slidingly connected with a transfer mechanism, the upper surface of the support frame 1 is fixed with a transmission mechanism by bolts, one side of the installation frame 2 is fixed with a feed trough 5 by bolts, and one side of the feed trough 5 is fixed by bolts There is a material guide plate 501, a slide hole 502 is opened at the bottom of the material guide plate 501, and a slider 505 is slidably connected in the slide hole 502, one end of the slider 505 is fixedly connected with the bottom of the material guide plate 501 by bolts, and the top of the slider 505 is connected by a bolt T...

Embodiment 2

[0036] refer to Figure 5-Figure 6 , a solar photovoltaic cell production and processing equipment, one side of the placement seat 9 is fixed with an extension plate 10 by bolts, and the upper surface of the extension plate 10 is provided with a plurality of rotating grooves, and the inner wall of the rotating groove is rotatably connected with a rolling column 1001, and the rolling column 1001 It can help photovoltaic cells to be unloaded slowly, thereby improving the bonding quality of photovoltaic cells to a certain extent. There are two insertion slots 1002 on one side of the mounting frame 2, and insertion rods are inserted into the inner walls of the insertion slots 1002 1003, one side of the plug rod 1003 is fixed with a discharge plate 1004 by bolts, and the upper surface of the discharge plate 1004 is fixed with two baffles 1005 by bolts, the baffles 1005 can prevent the solar photovoltaic cells from slipping, and the baffles 1005 are located in the extension plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com