Turning device for output shaft of parallel-axis gearbox

An output shaft and gear box technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as affecting assembly accuracy, damage to the tip of gear teeth, ground damage, etc., and achieve the effect of convenient work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

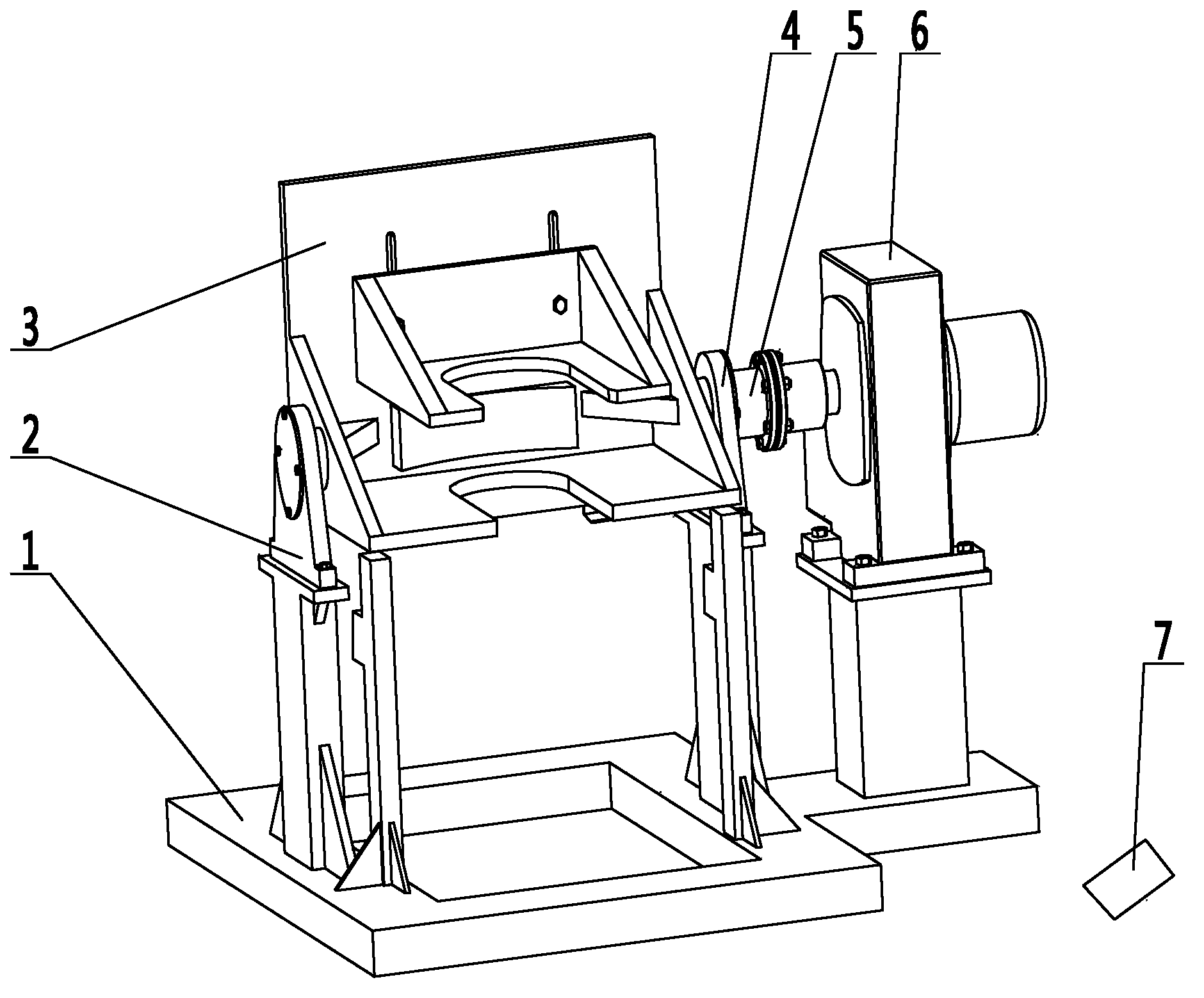

[0020] figure 1 Insert the left end bearing seat (2) and the right end bearing seat (4) respectively into the left and right end shaft heads of the turning frame (3), install the left end bearing seat (2) and the right end bearing seat (4) at the corresponding positions of the frame body (1) and fix them, remove the coupling (5) Install them on the shaft head at the right end of the overturn frame ⑶ and the output shaft of the reducer ⑹, place the reducer ⑹ on the corresponding position of the frame body ⑴, combine the coupling ⑸ and fasten the reducer ⑹ on the frame body (1) on. The worker puts the pressed output shaft and output gear on the overturn frame ⑶, steps on the forward foot switch ⑺, the output shaft of the reducer ⑹ drives the overturn frame ⑶ to rotate forward through the coupling ⑸, and stops automatically when it reaches the designated position After the assembly is completed, the worker steps on the reverse foot switch⑺, the output shaft of the reducer ⑹ driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com