Composite material long purlin milling flexible tool and clamping method of same

A composite material and cutting flexible technology, applied in the direction of clamping, positioning devices, clamping devices, etc., can solve the problems of prolonging the production cycle, wasting resources, increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

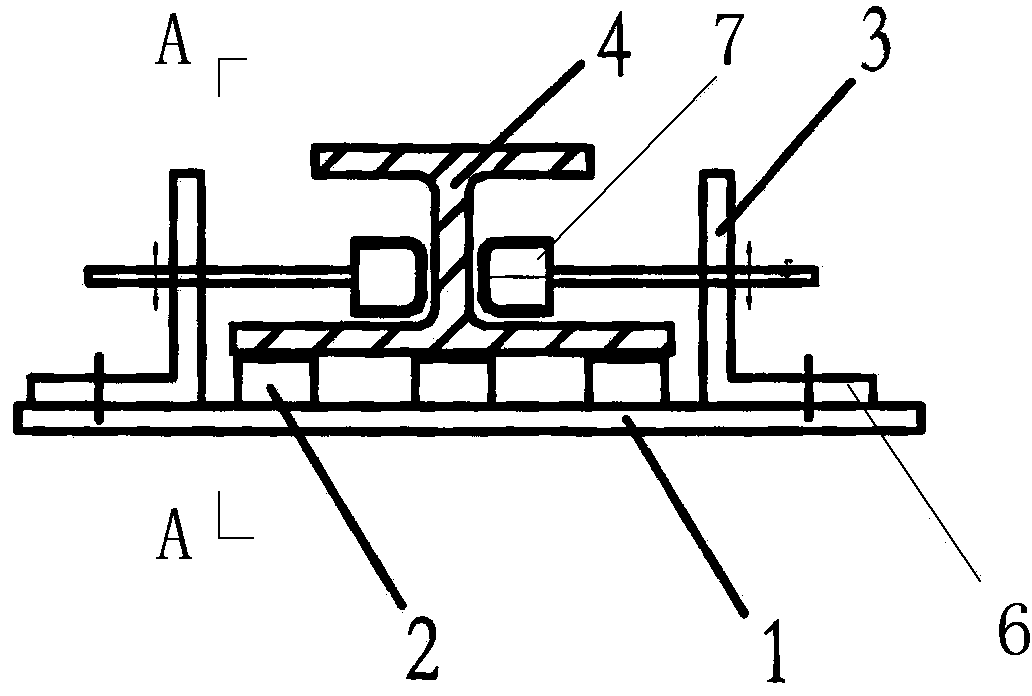

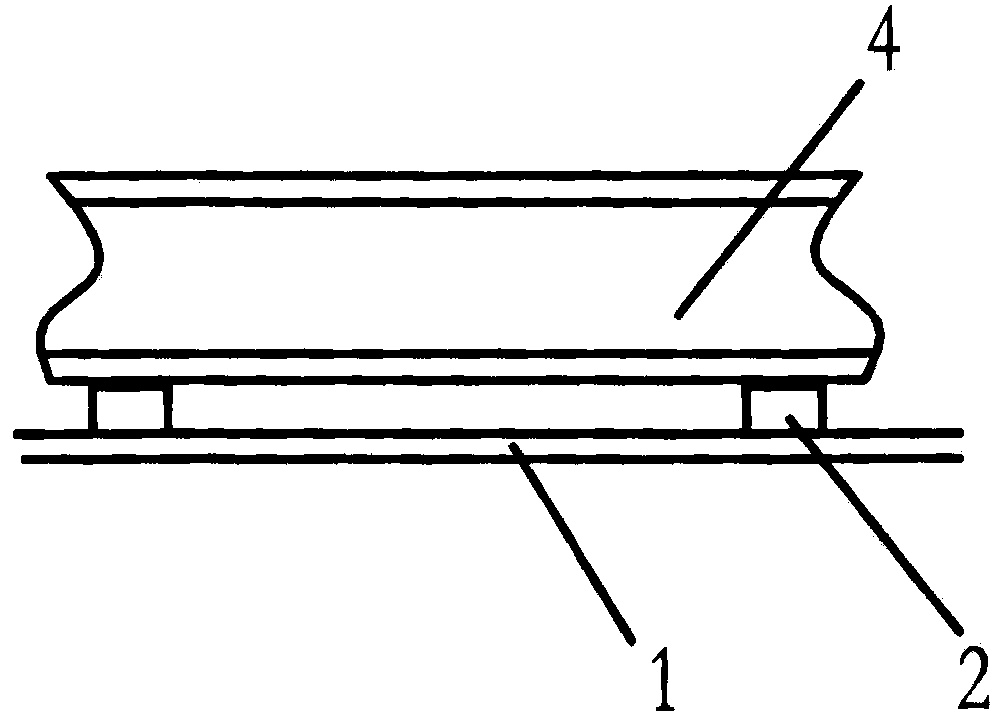

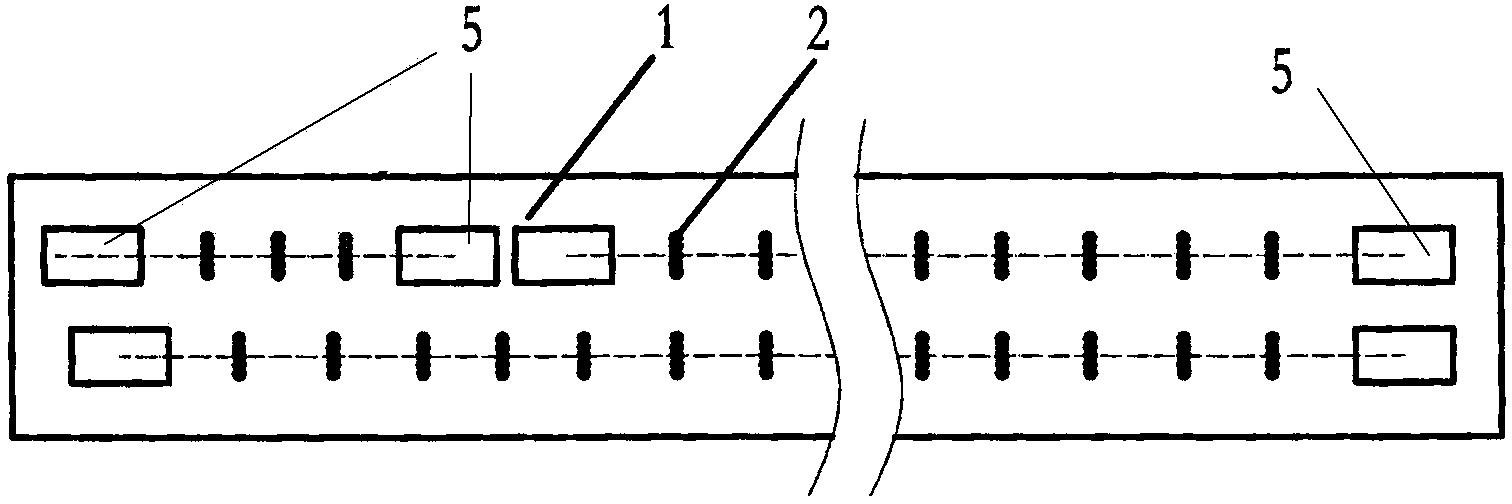

[0016] Such as Figure 1 to Figure 3 As shown in the figure, the composite long-truss milling and cutting flexible tooling is provided with long-truss axis positioning blocks 5 at both ends of the reference platform 1, and the long-truss axis positioning block 5 at one end is fixedly connected with the reference platform 1, and the other end is connected with the reference platform 1 1 Movable connection; between the two long truss axis positioning blocks 5, there are several sets of evenly distributed support devices, each set of support devices is composed of several support blocks 2 with a support spacing of 10-20 mm, and the middle support block 2 is located directly below the axis of the truss, and the remaining support blocks 2 are symmetrically distributed along the axis; L-shaped positioning plates 6 are arranged on both sides of each set of supporting devices, and height-adjustable clamping and pressing plates are arranged on the positioning plates 6 The device 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com