Glazing system for green bodies of ceramic pots

A technology for ceramic pots and green bodies, which is applied in the field of continuous glazing device systems for open ceramic products, which can solve the problems of inability to realize continuous production, low efficiency, and high labor intensity of workers, and improve the operating environment of workers and improve The effect of production efficiency and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

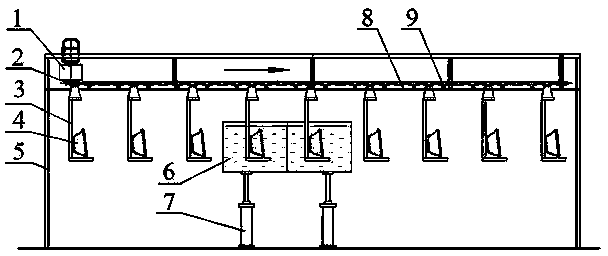

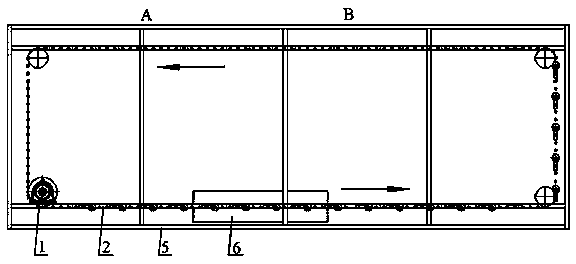

[0016] Such as figure 1 , 2 As shown, the ceramic pan body glazing system is composed of a frame 5, a chain 2, a hanger 3, a transmission mechanism 1, a glaze pool 6, and a hydraulic lifting device 6. The system adopts a circular guide rail transmission structure. The rollers rotate on the guide rails, and the chain rotates circularly on the guide rails through the rollers. The green body hanger 3 devices are installed on the chain at regular intervals. The chain adopts a flap type chain, and rollers are installed on the fins of the chain.

[0017] The working principle and process of the present invention are as follows: put the ceramic pot body 4 on the hanger 3 hanging on the chain at the blanking station A, and the chain 2 rotates forward along the direction of the arrow, when the ceramic pot body 4 When it reaches the top of the glaze pool 6, the chain 2 stops rotating, and the glaze pool hydraulic lifting mechanism 7 lifts the glaze pool 6 filled with glaze water, so t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap