Method for preparing 1,5-pentanediol via selective hydrogenolysis of tetrahydrofurfuryl alcohol

A technology of tetrahydrofurfuryl alcohol and selectivity, applied in the field of selective hydrogenolysis to prepare 1,5-pentanediol, which can solve the problems of high price of noble metal Rh and limited catalyst application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

[0021] Preparation of Catalyst by Impregnation Method

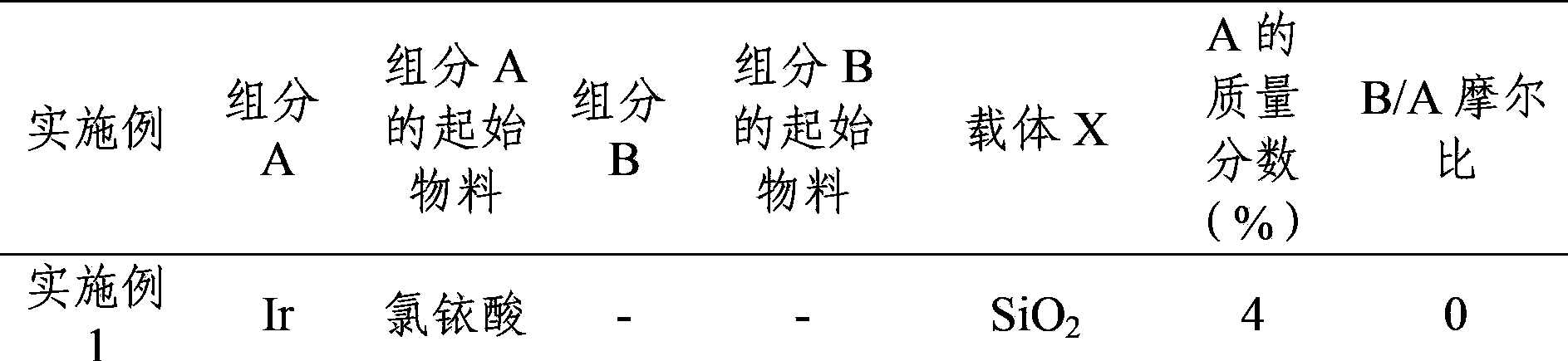

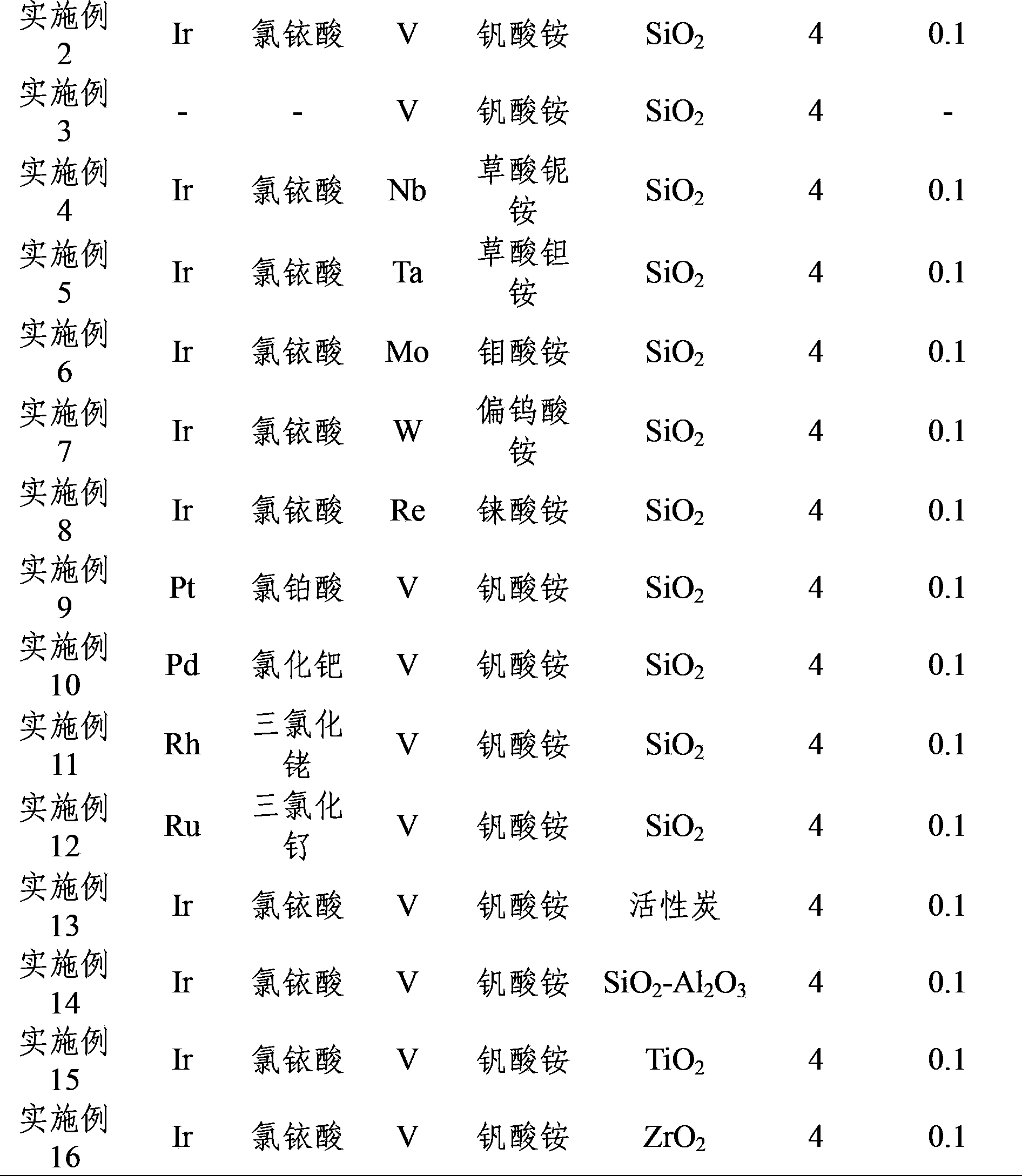

[0022] Add 10% soluble salt solution containing A to the carrier for impregnation according to a certain metering ratio, age at room temperature for 12 hours, and then dry in an oven at 120°C for 12 hours; then weigh the components according to a certain B / A molar ratio The soluble salt solution of B is added to the above-mentioned carrier impregnated with component A, aged at room temperature for 12 hours, then dried at 120°C for 12 hours, and calcined in air at 500°C for 3 hours to obtain the supported type A-B / X catalyst. The composition of catalyst in each embodiment, the kind of starting material of component A, B is shown in Table 1.

[0023] Table 1. The composition of each catalyst

[0024]

[0025]

Embodiment 17

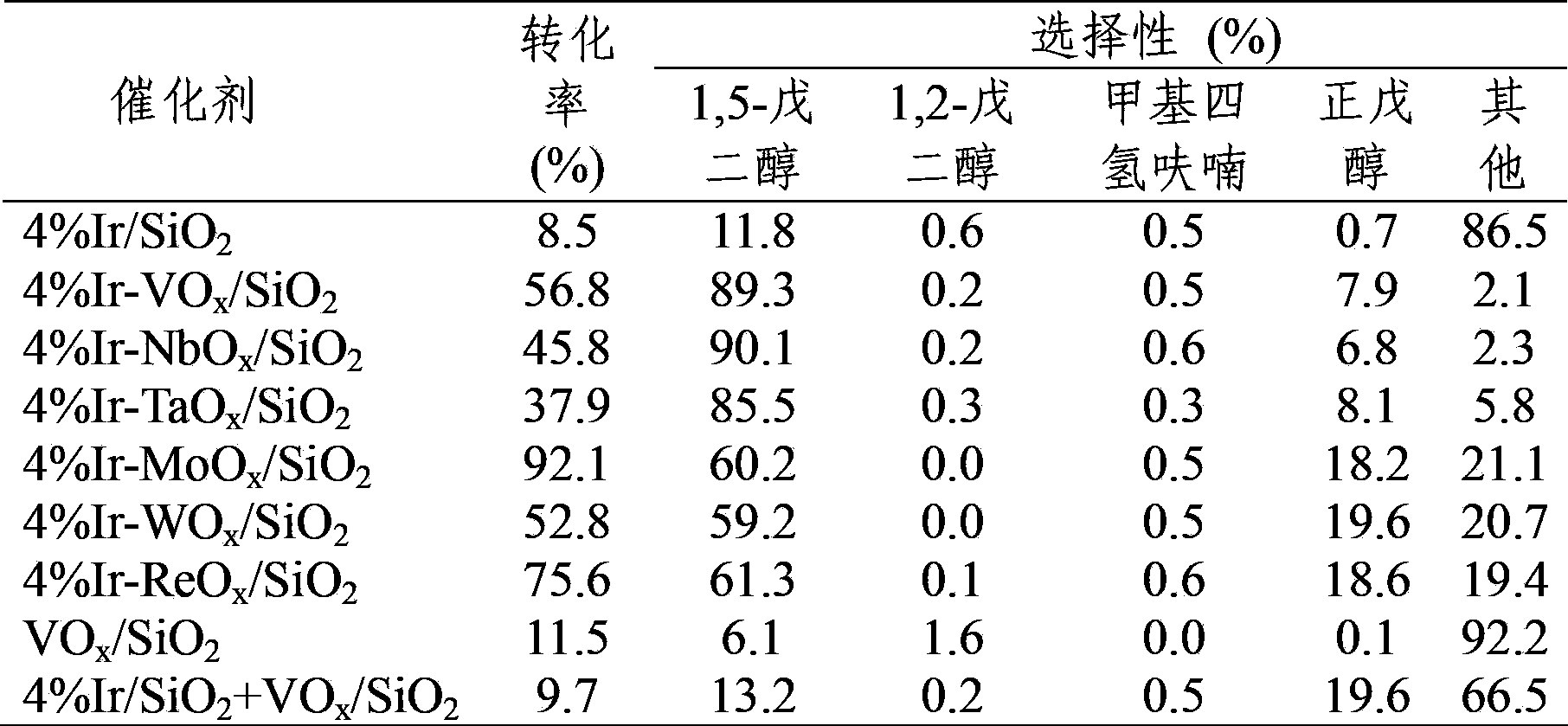

[0027] Catalyst activity evaluation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com