Water-soluble self-drying epoxy modified alkyd automobile chassis paint

An epoxy modification, automotive chassis technology, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as rust, and achieve good durability, rapid drying, and no bark.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw material composition:

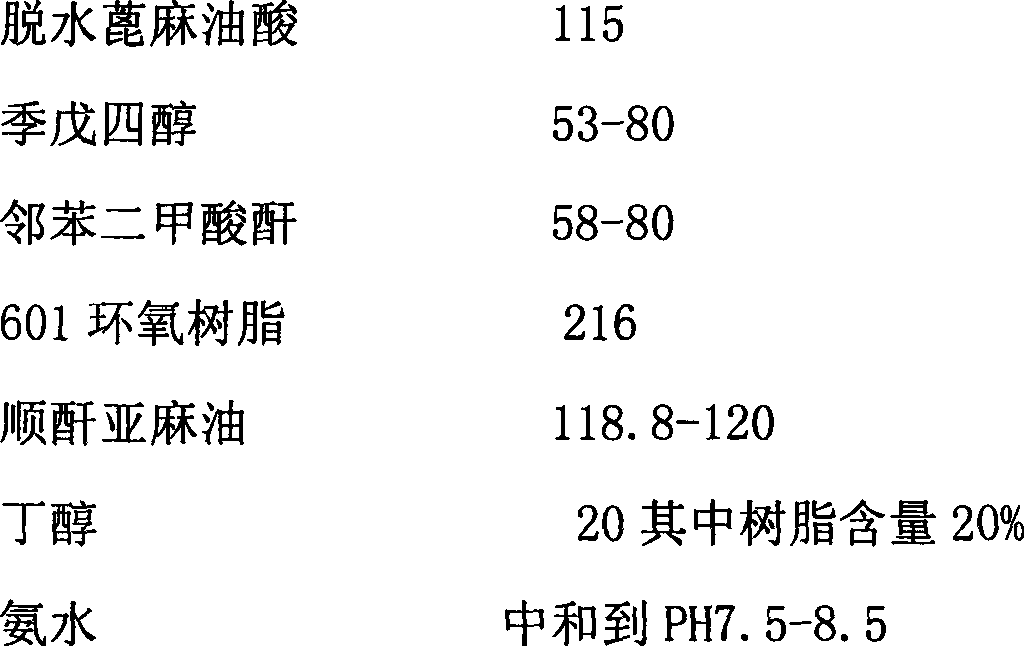

[0024] 1. Water-soluble self-drying epoxy modified alkyd resin:

[0025]

[0026] 2. Mixed dry ingredients:

[0027]

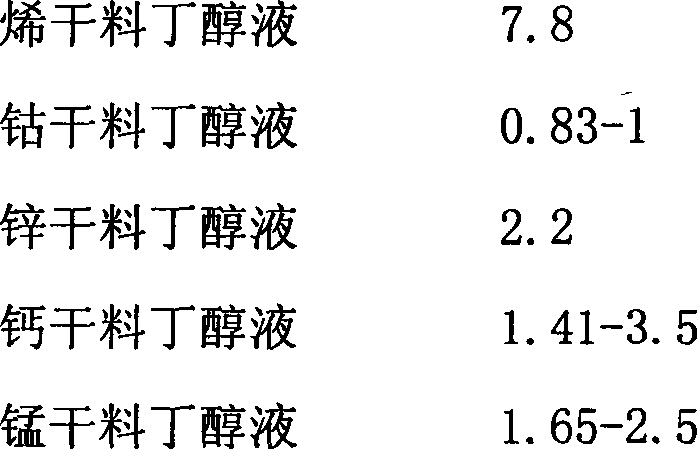

[0028] 3. Black chassis paint:

[0029]

[0030] Prepared by conventional methods.

Embodiment 2

[0032] Raw material composition:

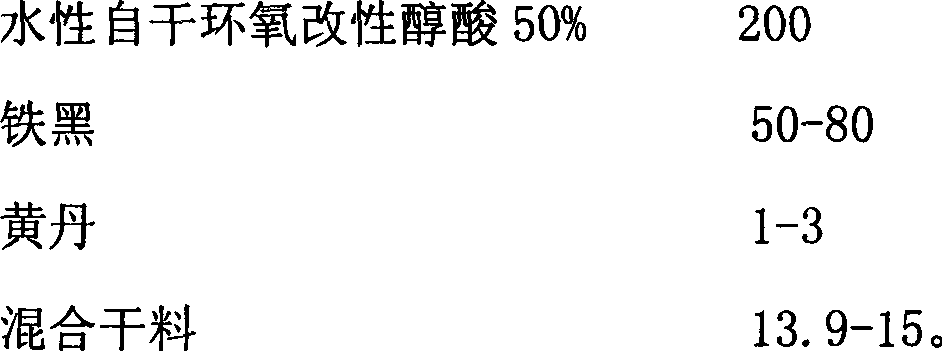

[0033] 1. Water-soluble self-drying epoxy modified alkyd resin:

[0034]

[0035]

[0036] 2. Mixed dry ingredients:

[0037]

[0038] 3. Black chassis paint:

[0039]

[0040] Prepared by conventional methods.

Embodiment 3

[0042] 1. Water-soluble self-drying epoxy modified alkyd resin:

[0043]

[0044] 2. Mixed dry ingredients:

[0045]

[0046]

[0047] 3. Black chassis paint:

[0048]

[0049] Prepared by conventional methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com