High-intensity polypropylene geotechnical cloth

A technology of polypropylene and geotextiles, which is applied in water conservancy projects, sea area projects, construction, etc., can solve the problems of low elongation, poor acid and alkali corrosion resistance, general production process, etc., to achieve reduced gaps, high product quality, The effect of improving product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

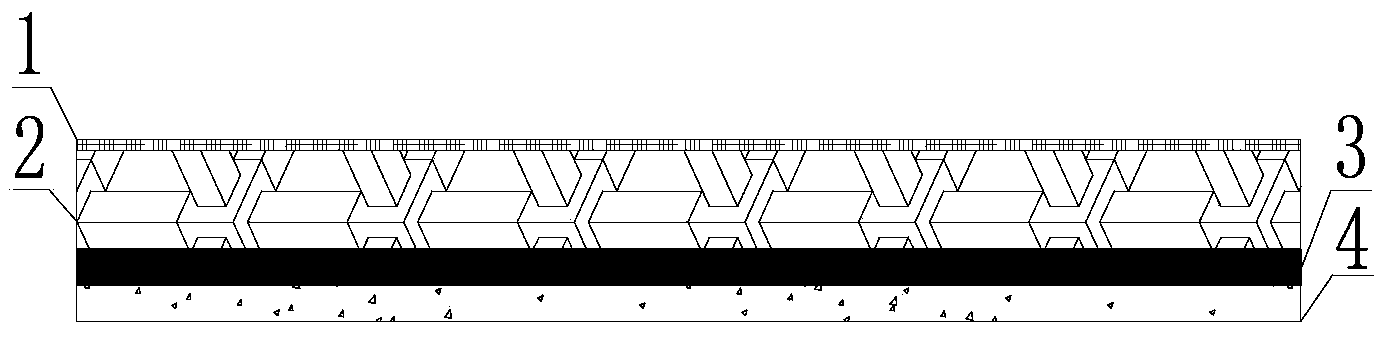

[0015] Such as figure 1 Shown, a kind of high-strength polypropylene geotextile of the present invention, it comprises singeing layer 1, is provided with non-woven fabric layer 2 under described singeing layer 1, is provided with under described non-woven fabric layer 2 Water-repellent layer 3, below described water-repellent layer 3 is provided with ironing layer 4, and they are closely combined with each other; The width is between 4.2-8m; the non-woven fabric layer 2 is a needle-punched non-woven fabric layer. In the present invention, after scalding treatment, the water-repellent layer is firmly fixed on the surface layer of the non-woven fabric, and forms a smooth surface, so that it can be better combined with polyurethane glue during the construction of the high-speed rail sliding layer in the later stage. The invention shrinks the fiber fleece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com