Stair tread pouring formwork

A technology for stair treads and formwork, which is applied in the direction of formwork/formwork/work frame, architecture, building structure, etc., can solve the problems of increasing the time for dismantling the formwork, poor stair forming effect, etc., so as to improve the stair forming effect and construction quality. , The effect of convenient dismantling and lower construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

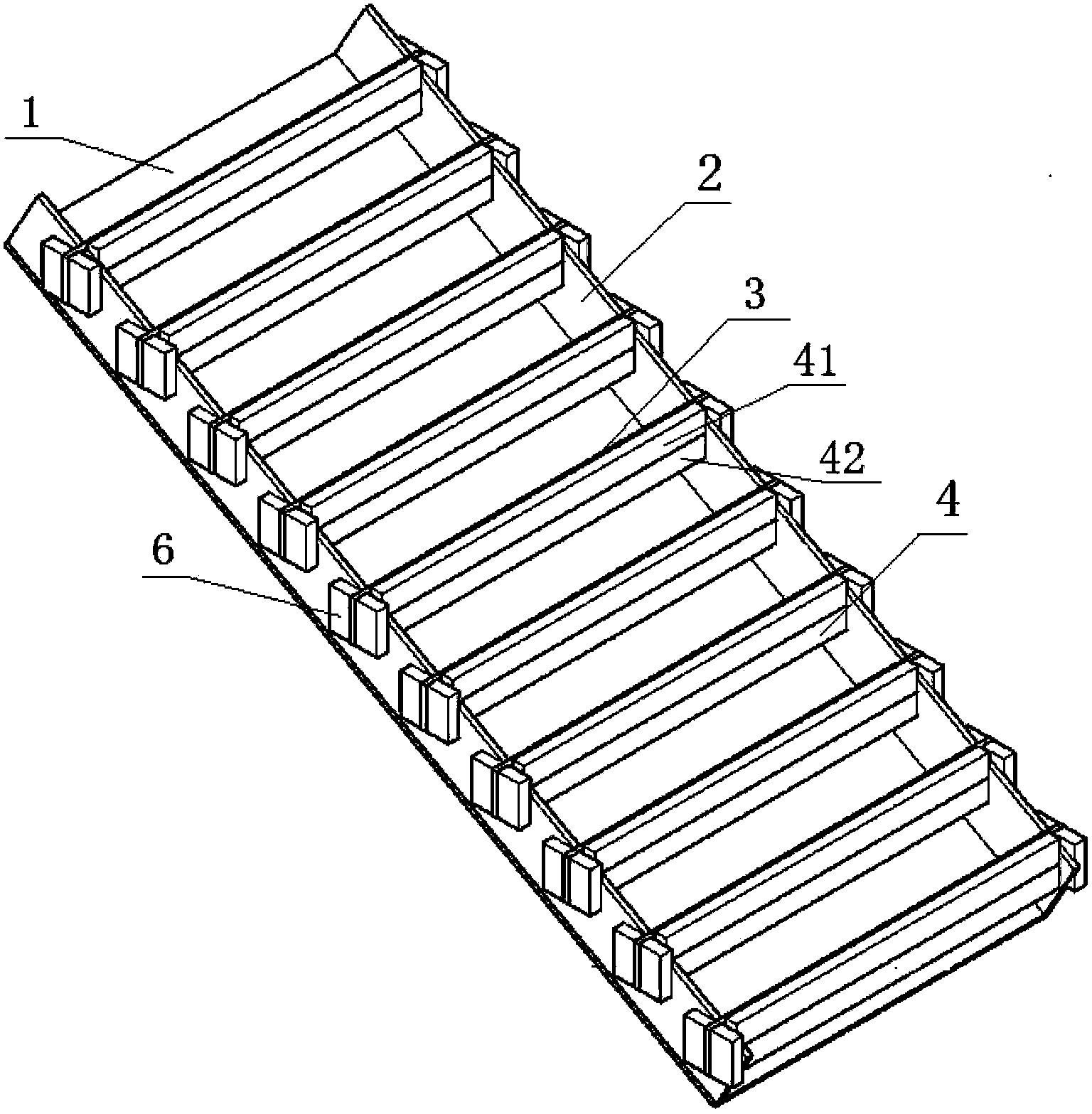

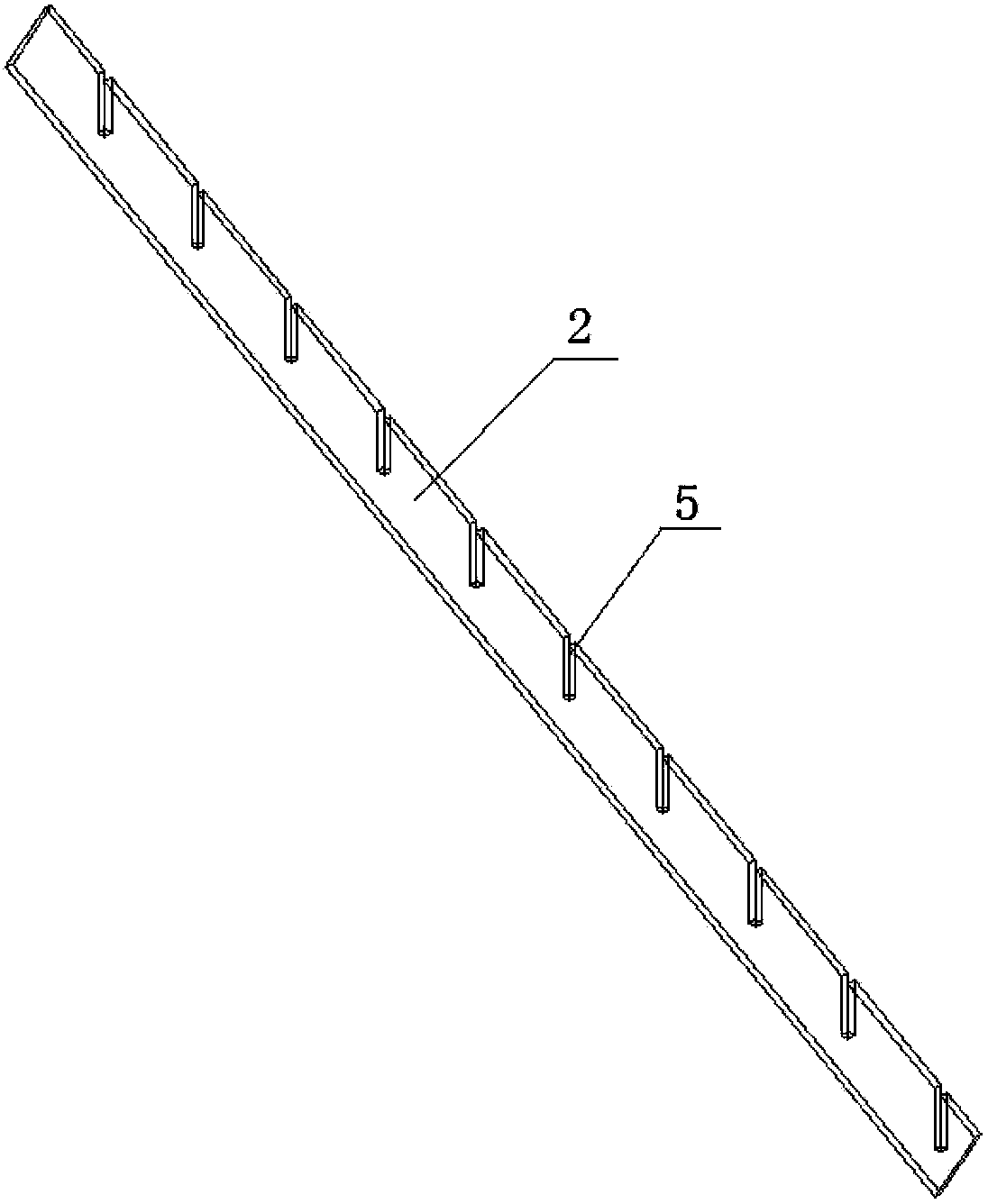

[0013] Example: such as figure 1 and figure 2 As shown, a stair tread pouring formwork is composed of a base form 1, a side form 2 arranged on both sides of the base form 1, a skirting surface formwork 3 and a reinforcing plate 4 arranged on one side of the skirting surface formwork 3, the reinforcing plate 4 is made up of upper crosspiece wooden side 41 and lower crosspiece wooden side 42. The upper side of the side form 2 is provided with a sawtooth groove 5 at the position corresponding to the skirting surface of the stair tread, and the two ends of the skirting surface template 3 are respectively inserted into the sawtooth groove 5 of the sideform 2, and the outer side of the sideform 2 is provided with a sawtooth groove 5. A splint 6 is arranged, and the splint 6 is made up of two planks fixed on the outside of the side form 2 , and the part of the skirting surface template 3 protruding from the sawtooth groove 5 is sandwiched between the two short wooden sides of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com