Range hood and control method thereof

A range hood and range hood technology, which is applied in the fields of removing range hood, heating method, and household heating, etc., can solve the problem of not being able to meet the oil absorption efficiency, and achieve the effect of improving the oil absorption efficiency, strong adaptability, and increasing the oil absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

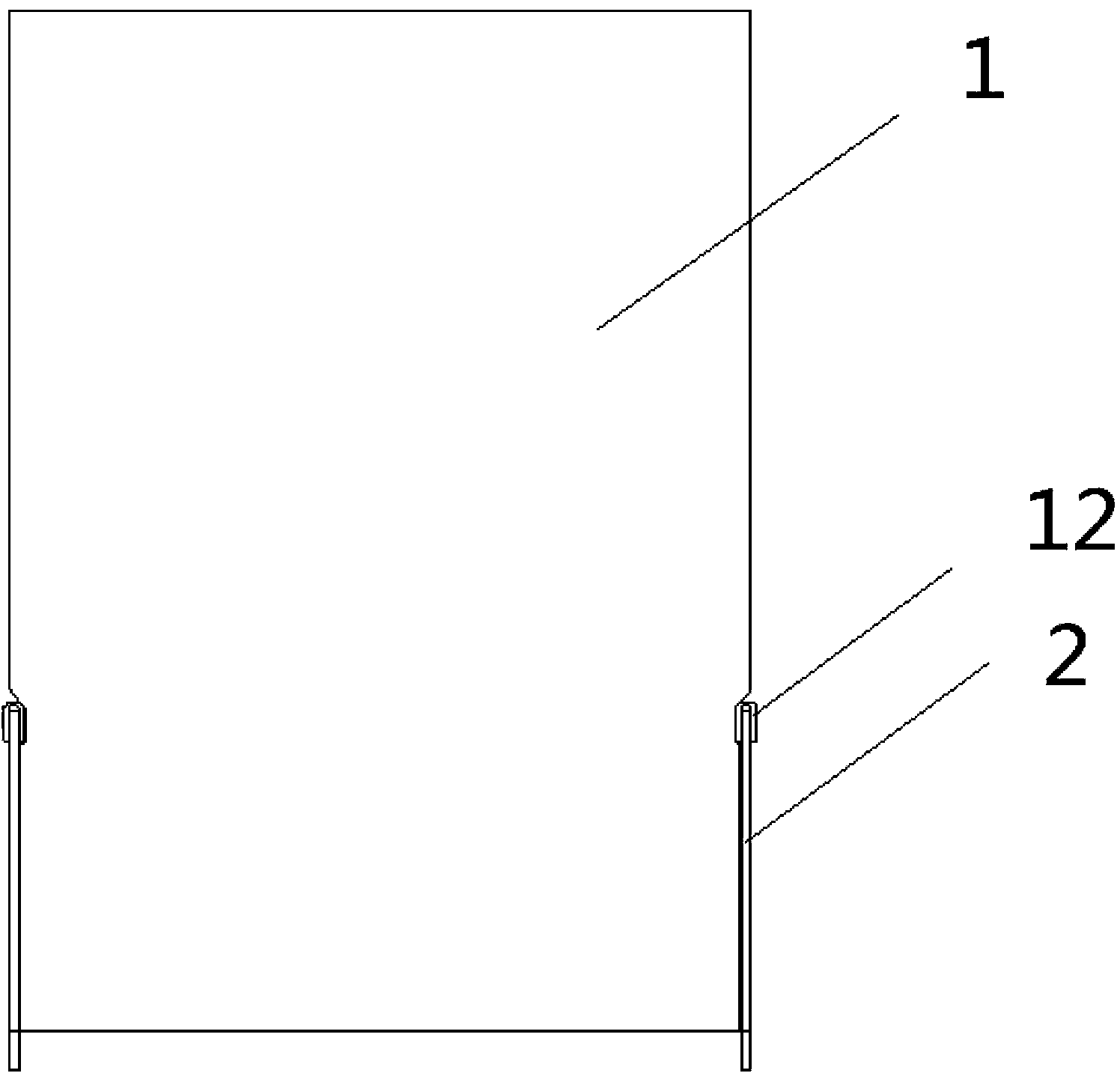

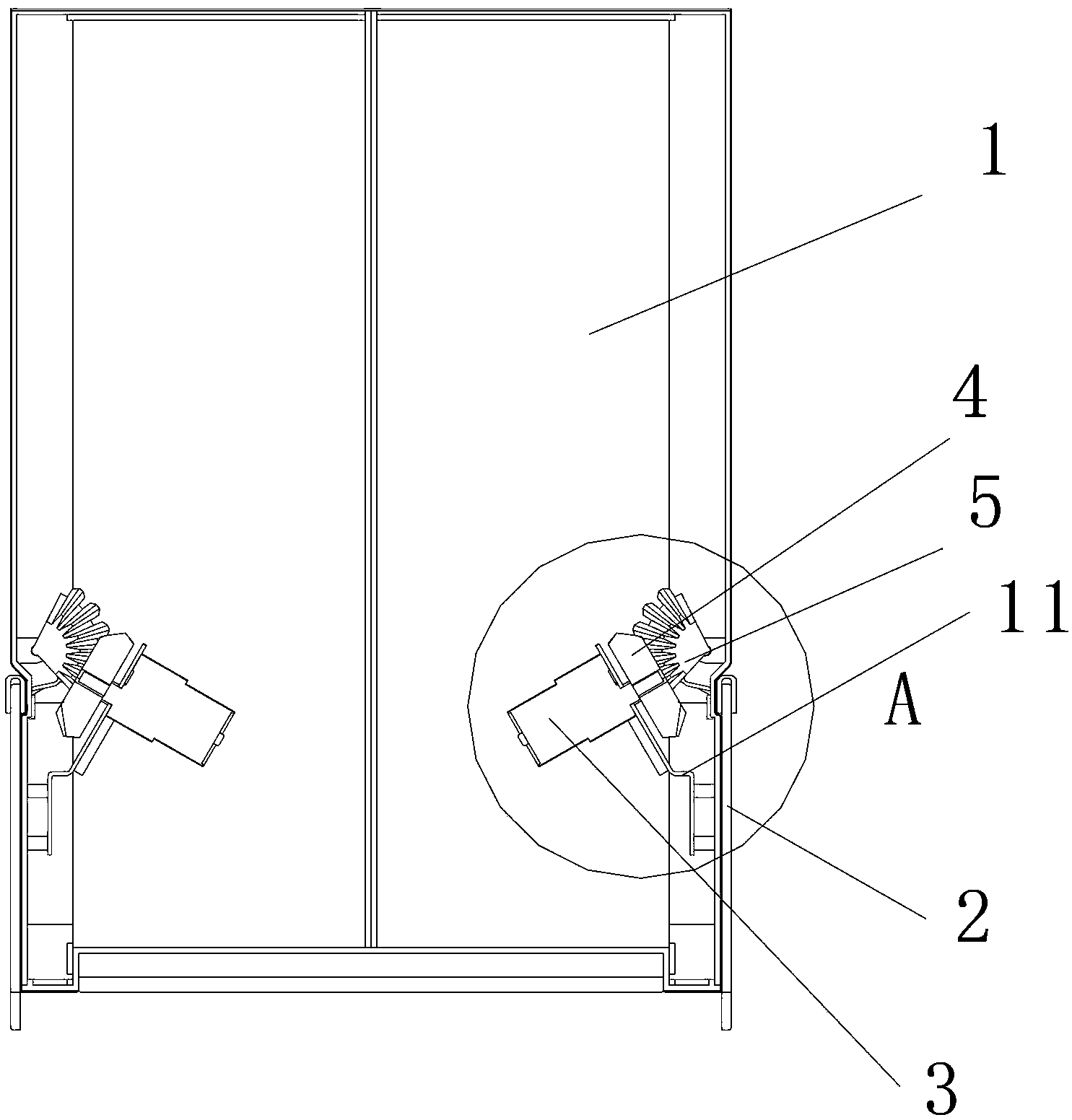

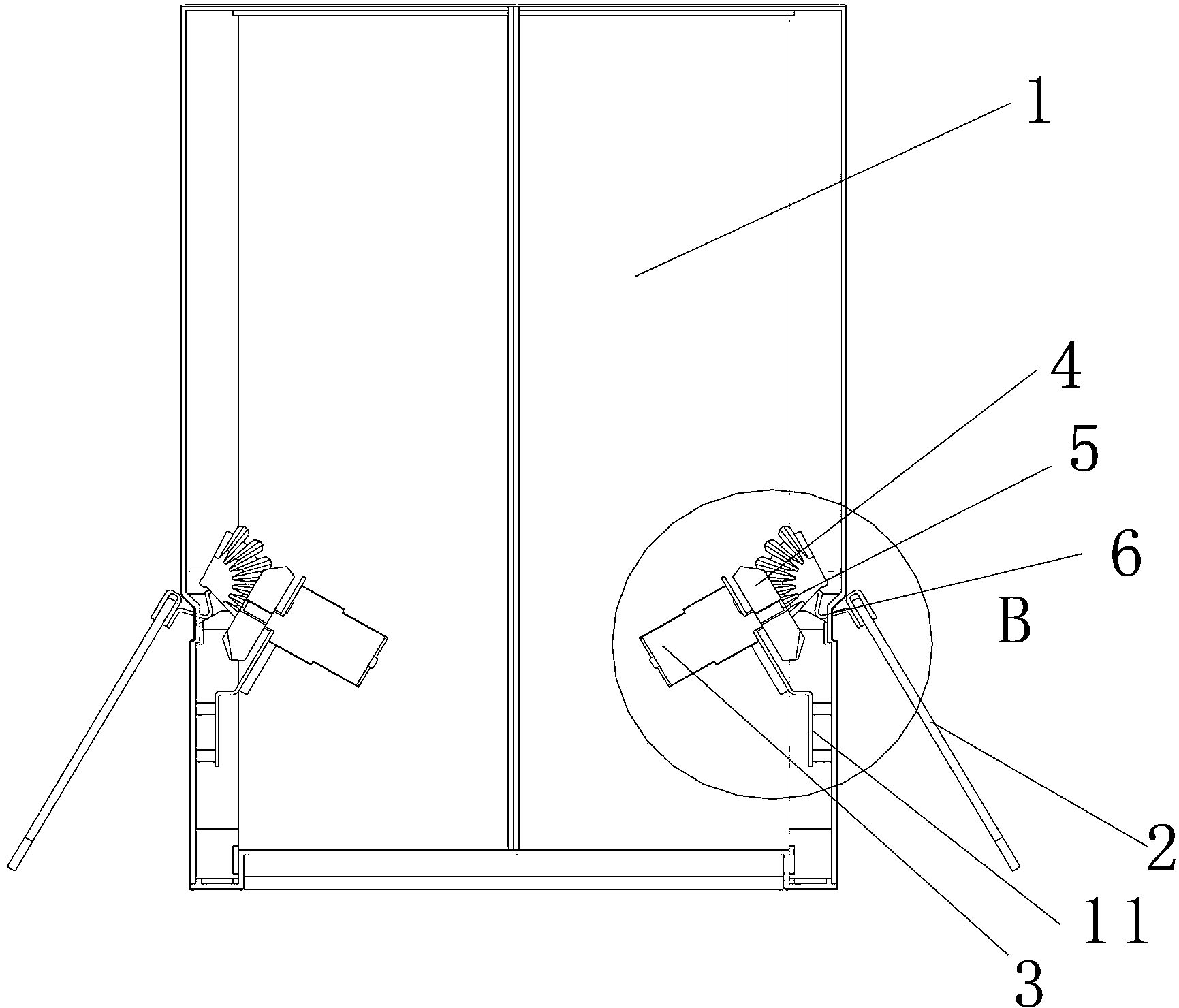

[0026] see Figure 1-Figure 6 , the range hood of this embodiment includes:

[0027] Range hood body 1;

[0028] The baffles 2 arranged on both sides of the range hood body 1 can be deployed to both sides of the range hood body 1 respectively;

[0029] A rotary drive mechanism connected to the baffle 2 for driving the baffle 2 to rotate to adjust the current degree of expansion of the baffle.

[0030] Optionally, the range hood also includes an automatic control system that controls the rotary drive mechanism to drive the baffle 2 to rotate;

[0031] The automatic control system includes:

[0032] The sensor 7 is arranged on the range hood body 1, and is used to detect and send the amount of oil fume information;

[0033] The comparator 8 stores the preset threshold value of the oil smoke amount information, is connected to the sensor 7, and is used to receive the oil smoke amount information sent by the sensor 7, compare it with the preset threshold value, and send the co...

Embodiment 2

[0052] see Figure 7 , this embodiment provides a control method for the range hood described in Embodiment 1, comprising the following steps:

[0053] S10: Obtain the current amount of oil fume in the space where the range hood body is located;

[0054] S20: Generate a rotation control signal according to the oil fume amount information;

[0055] S30: Send the rotation control signal to the rotation driving mechanism, for instructing the rotation driving mechanism to drive the baffle to rotate to adjust the current degree of expansion of the baffle.

[0056]Optionally, the acquiring the current oil smoke amount information in the space where the range hood body is located includes: detecting the current oil smoke amount information in the space where the range hood body is located by the sensor and sending it to the comparator; according to the oil smoke amount information Generating the rotation control signal includes: a comparator storing a preset threshold value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com