IGBT device and forming method thereof

A device and semiconductor technology, applied in the field of IGBT devices and their formation, can solve problems such as poor performance of IGBT devices, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

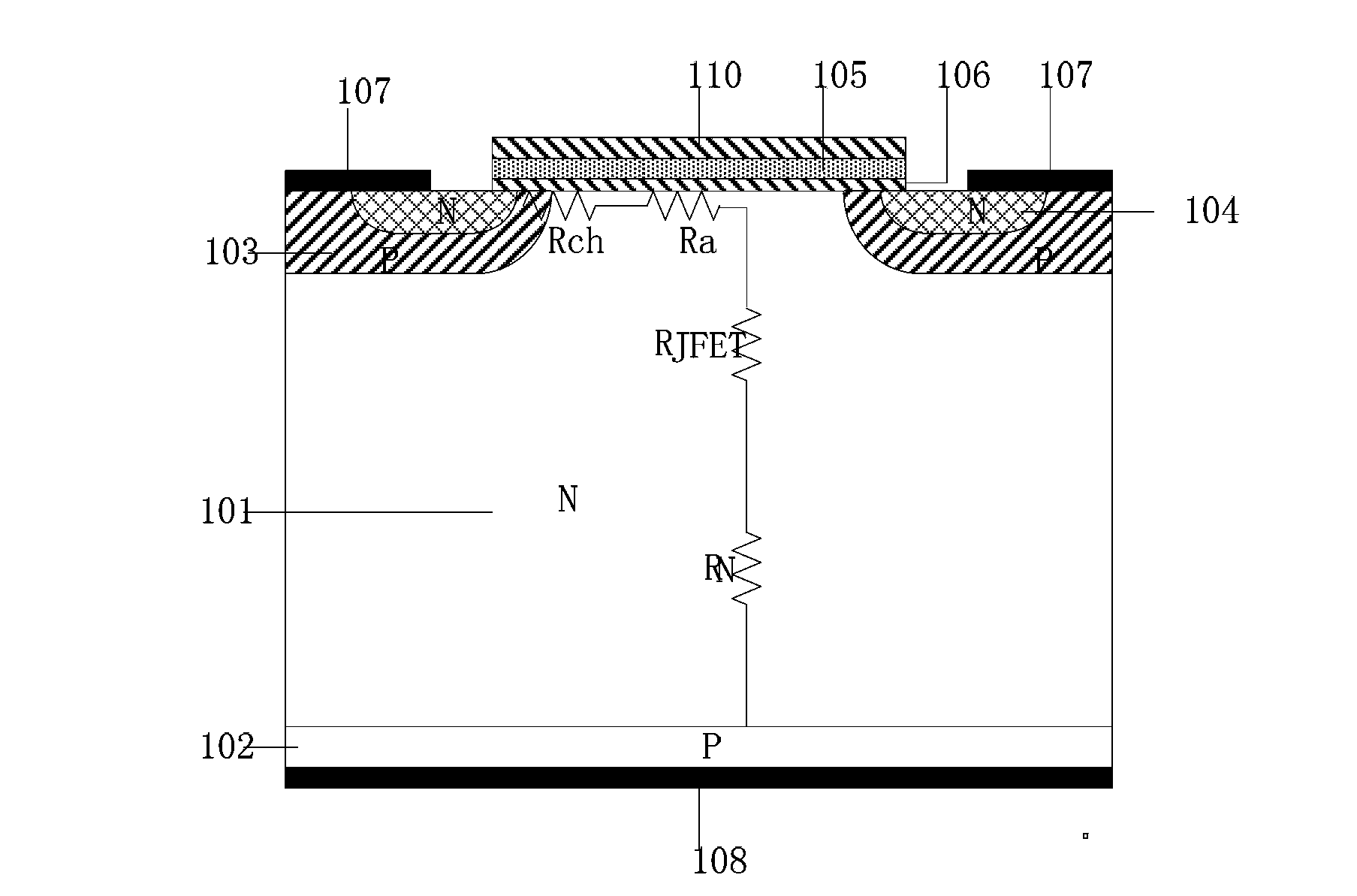

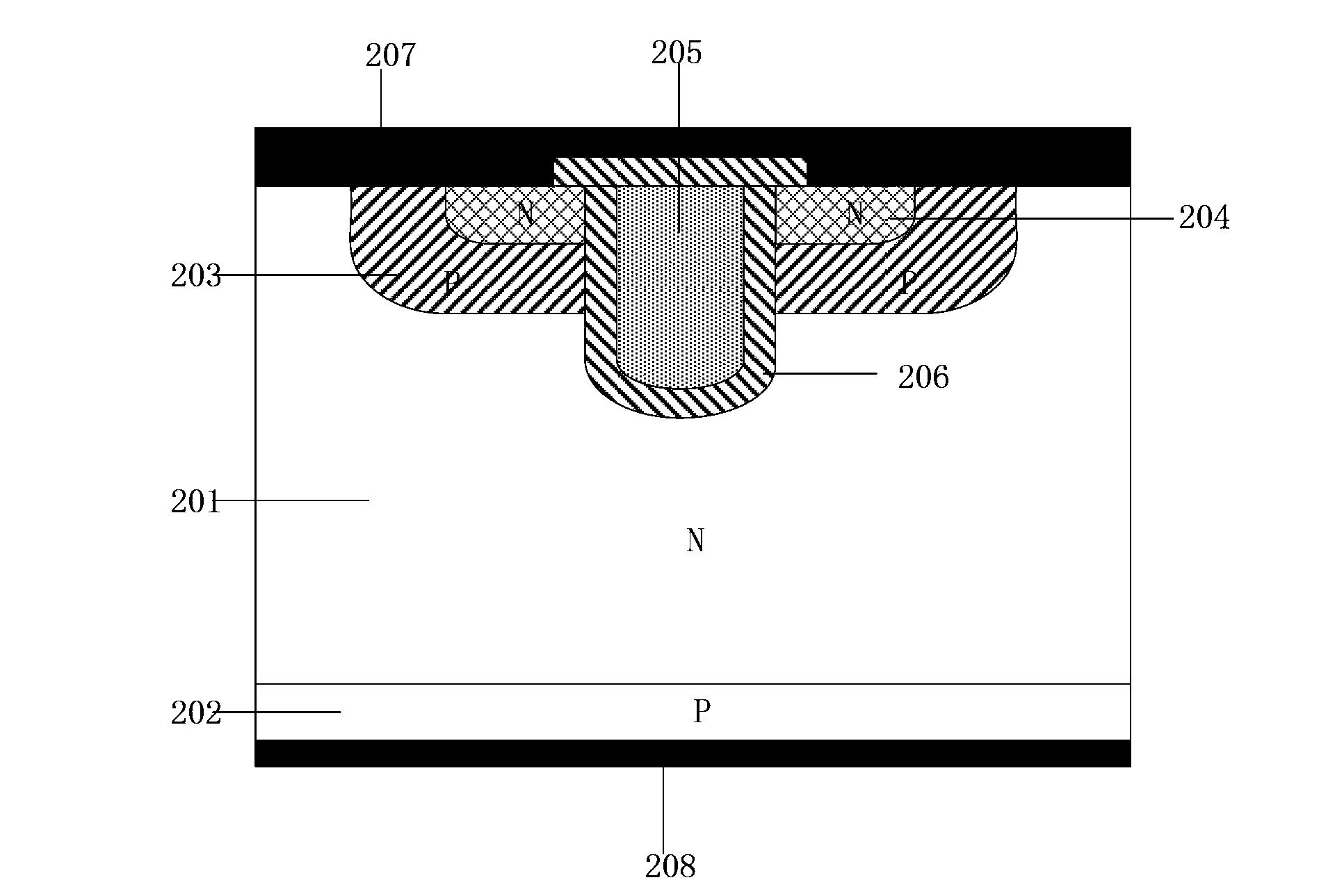

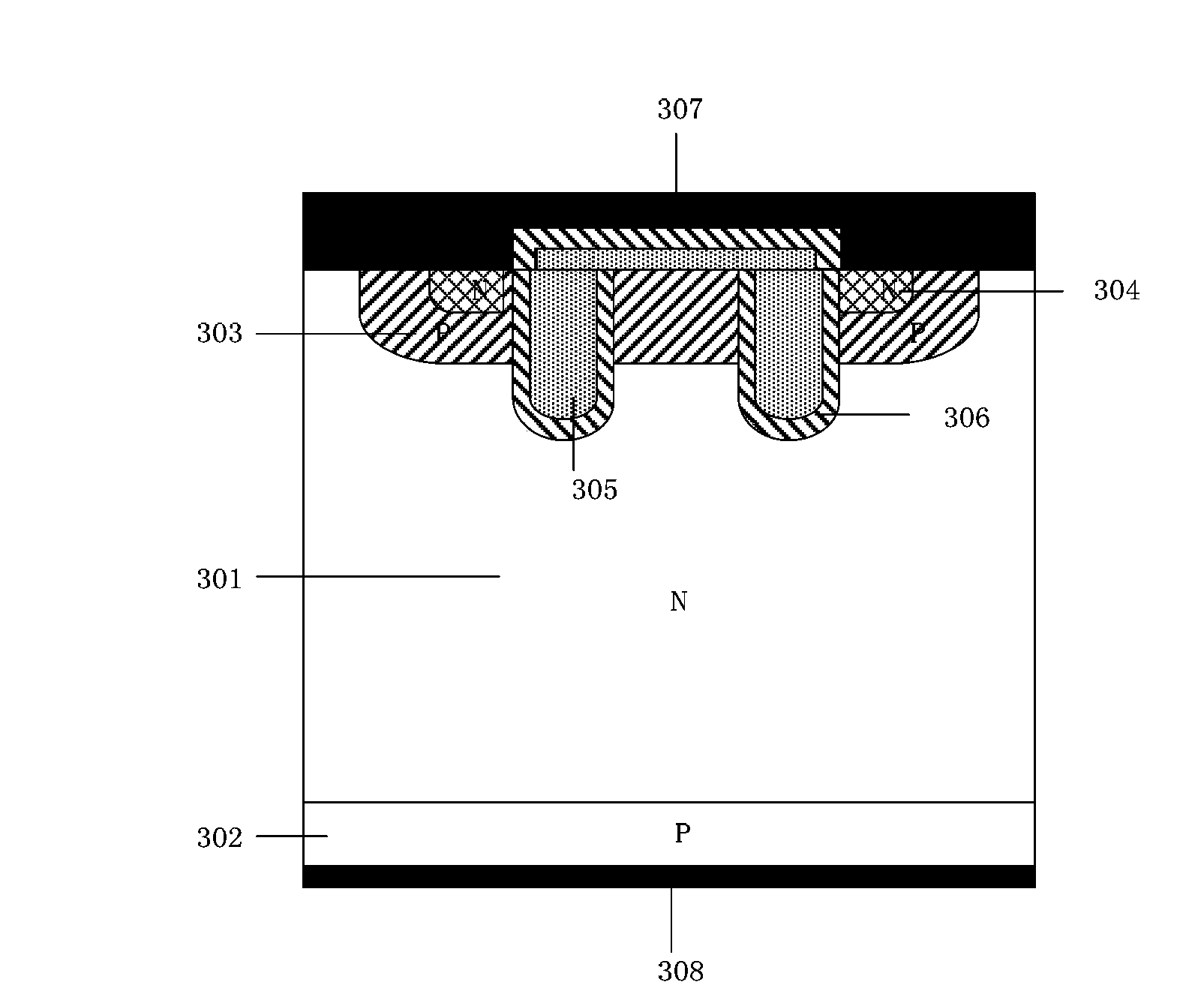

[0068] Such as Figure 5 As shown, the IGBT device provided by the embodiment of the present invention includes:

[0069] A semiconductor substrate including a drift region 501 . In the IGBT device provided by the present invention, the semiconductor substrate can be N-type doped or P-type doped. In this embodiment, the semiconductor substrate is N-type doped as an example. The provided IGBT device is introduced, but the present invention is not limited thereto.

[0070] a base region 503, the base region 503 is formed in the upper surface of the semiconductor substrate, the doping type of the base region 503 is opposite to the doping type of the semiconductor substrate, and the upper surface of the base region 503 It is flush with the upper surface of the semiconductor substrate. In this embodiment, the base region 503 is a P-type base region.

[0071] A gate structure, the gate structure comprising a U-shaped portion and a horizontal portion, wherein the U-shaped portion ...

Embodiment 2

[0093] This embodiment provides a method for forming the IGBT device described in Embodiment 1, including:

[0094] Step S201 : preparing a substrate to provide a semiconductor substrate including a drift region 501 . In the method for forming an IGBT device provided by the present invention, the semiconductor substrate can be N-type doped or P-type doped. In this embodiment, the semiconductor substrate is N-type doped as an example. The IGBT device provided by the invention is introduced, but the invention is not limited thereto.

[0095] Step S202: performing ion implantation on the upper surface of the semiconductor substrate, and performing high-temperature annealing on the semiconductor substrate after ion implantation, so as to form a base region 503 in the upper surface of the semiconductor substrate, and the base region 503 The doping type is opposite to that of the semiconductor substrate, and the upper surface of the base region 503 is flush with the upper surface o...

Embodiment 3

[0115] This embodiment provides another method for forming the IGBT device described in Embodiment 1, including:

[0116] Step S301: Substrate preparation to provide a first semiconductor substrate, the first semiconductor substrate may be N-type doped, or P-type doped, and in this embodiment, the first semiconductor substrate is used as P-type doping is taken as an example to introduce the IGBT device provided by the present invention, but the present invention is not limited thereto.

[0117] Step S302: forming a second semiconductor substrate on the surface of the first semiconductor substrate, the second semiconductor substrate including a drift region 501, in this embodiment, the second semiconductor substrate and the first semiconductor substrate The doping type of the substrate is different, which is N-type doping, and the formation process is preferably an epitaxial process.

[0118] It should be noted that, in one embodiment of the present invention, before forming t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com