A kind of insulated gate field effect transistor and its manufacturing method

A technology for field effect transistors and manufacturing methods, which is applied in the field of insulated gate field effect transistors, can solve the problems of poor high-frequency switching characteristics of IGBT, reduce JFET resistance, limit application occasions, etc., and achieve high-frequency switching characteristics and small saturation The conduction voltage drop, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation and working principle of the insulated gate field effect transistor and its manufacturing method proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Describe in detail.

[0035] The insulated gate field effect transistor provided by the present invention includes: a graphene conductive layer; the graphene conductive layer is located between the gate oxide layer and the semiconductor layer in the non-channel region between the cell regions.

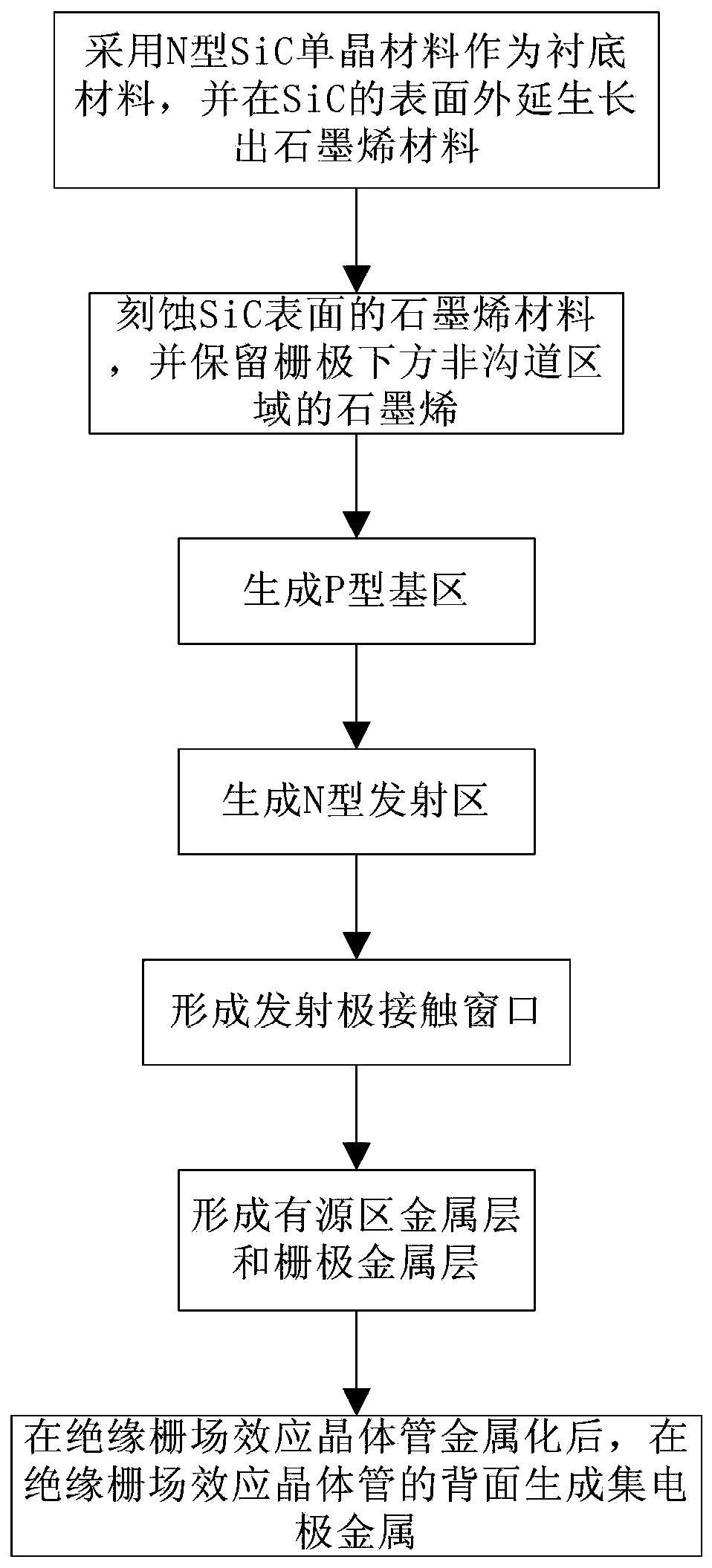

[0036] Depend on figure 1 It can be seen that the manufacturing method of the IGSFET provided by the present invention comprises:

[0037] N-type SiC single crystal material is used as the substrate material, and one or more layers of graphene materials are epitaxially grown o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com