Sweet potato vine reaper

A technology for sweet potato seedlings and harvesters, which is applied to harvesters, excavators, excavators, etc., can solve the problems of labor-consuming, time-consuming, low efficiency, and unsuitable for large-scale use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

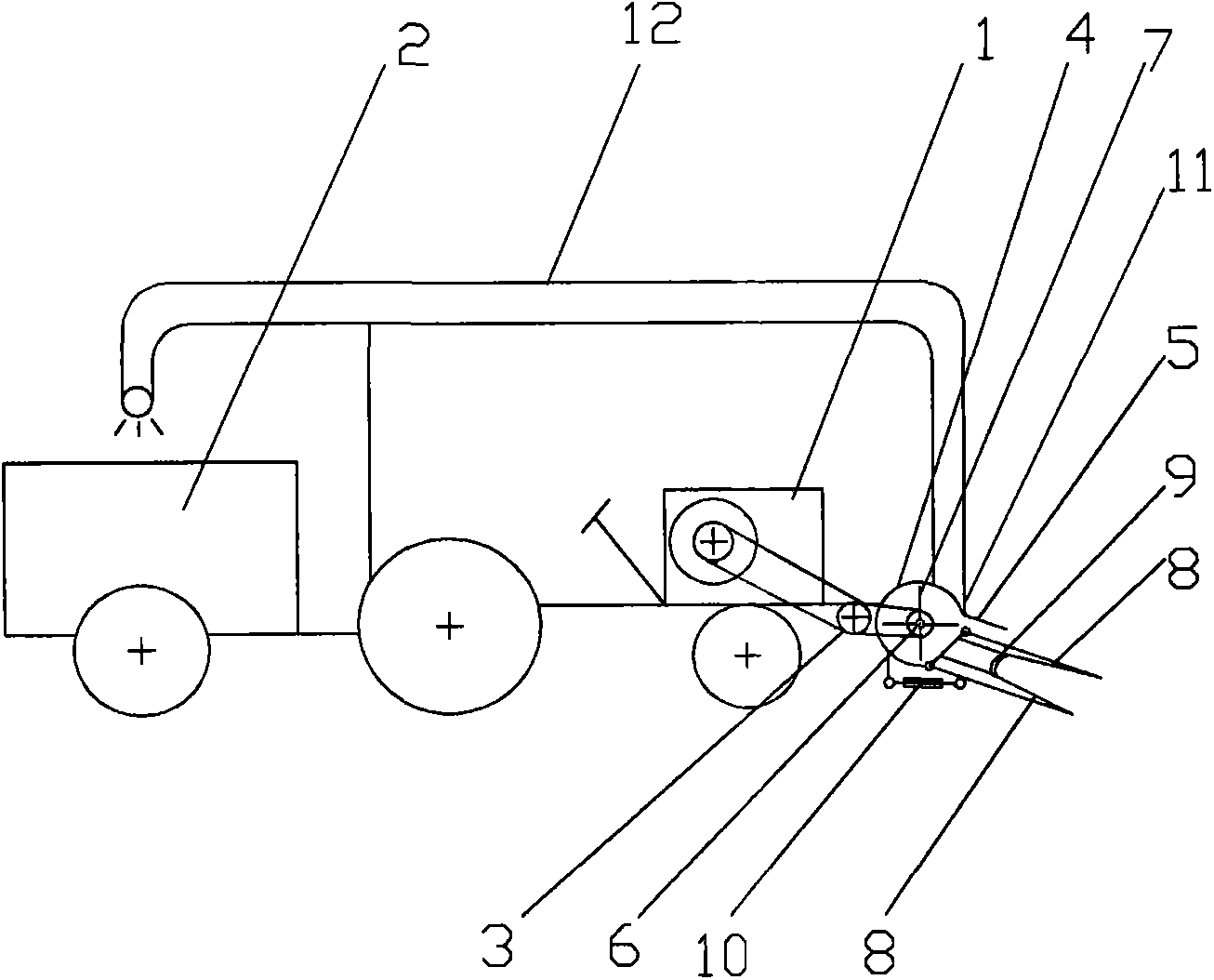

[0013] The sweet potato seedling harvester of the present invention is powered by the diesel engine (1) of the tractor in the middle, drives the sweet potato seedling harvesting and pulverizer (6) installed in the front, stirs up the sweet potato seedlings with the seedling lifter (8), and uses the seedling cutter (9) cut off the sweet potato seedling root, pulverize it with the pulverizer (6), and transport it to the dump truck bucket (2) behind the tractor through the centrifugal fan (11) delivery pipe (12); the sweet potato seedling harvesting pulverizer has: Intermediate belt pulley (3), "C" shaped shell frame (4), pulverizer (6), seedling picker (8), seedling cutting knife (9), seedling picker hydraulic lifting (10), centrifugal fan (11 ) and conveying pipe (12); the section of the shell frame of the pulverizer (6) is "C" shape (4); There is a protective plate (5) extending forward on the upper opening of the frame; the back of the "C"-shaped shell frame (4) has four symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com