A gas drying filter

A filter and filter cover technology, which is applied to chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of only applicable to gas drying treatment and high cost of gas transmission and distribution, and achieve the elimination of pressure regulator failures and reduce Equipment operating costs and the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

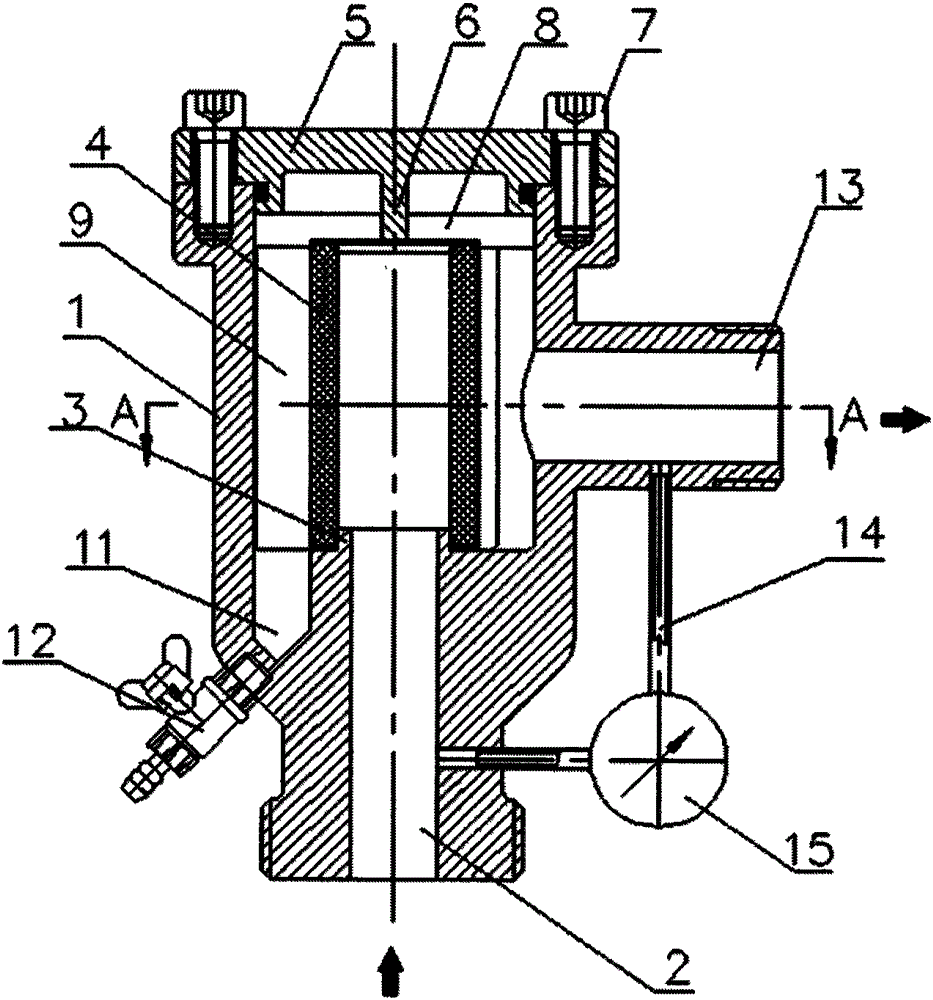

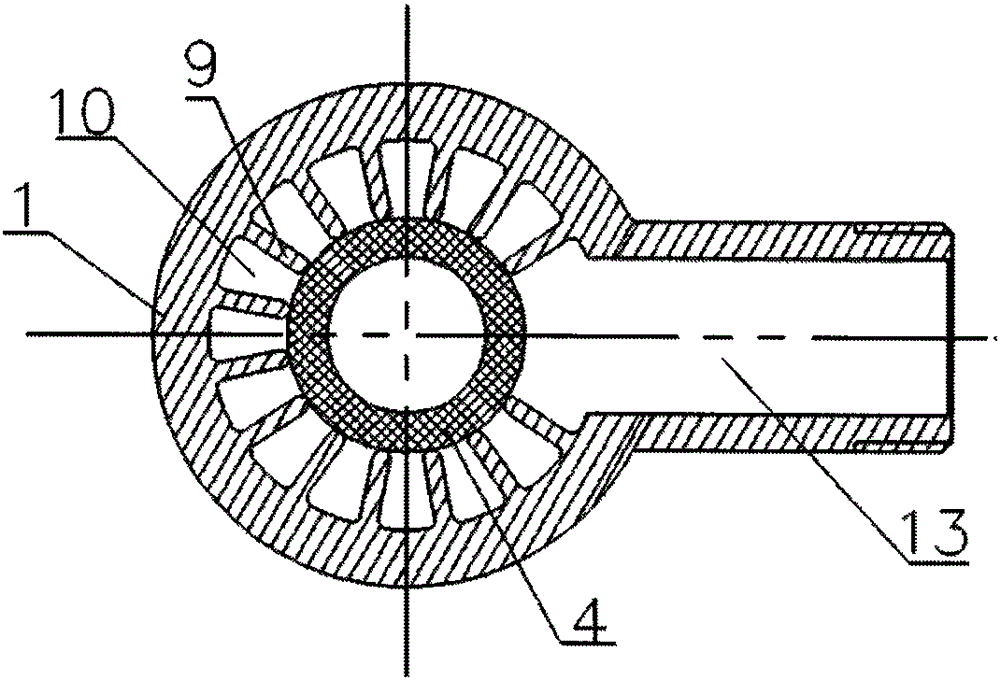

[0015] combine figure 1 and figure 2 , the specific embodiment of the present invention is described as follows:

[0016] A gas dry filter, which is composed of a filter body 1, a filter element 4, a filter cover 5, a water discharge valve 12 and a differential pressure gauge 14, and is characterized in that the filter body 1 is an integral structure, including an inlet cavity 2, a filter element seat 3. Unicom cavity 8, ice collection piece 9, ice chamber 10, water collection tank 11 and outlet cavity 13, the inlet cavity 2 is located at the lower end of the filter body 1, a filter element seat 3 is arranged above the inlet cavity 2, and the filter element 4 is a cylindrical barrel Shaped and reverse buckled on the filter seat 3, the central cylinder 6 of the filter cover 5 is tightly against the bottom of the filter element 4, and assembled on the upper end of the filter body 1 through the screw 7, the filter cover 5, the filter body 1 and the filter element 4 A communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com