Preparation method and application of Cu-Mn catalyst loaded on aluminum-pillared montmorillonite

A montmorillonite and catalyst technology, which is applied in the field of aluminum-pillared montmorillonite supported catalysts, achieves the effects of low energy consumption, mild reaction conditions and reduction of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

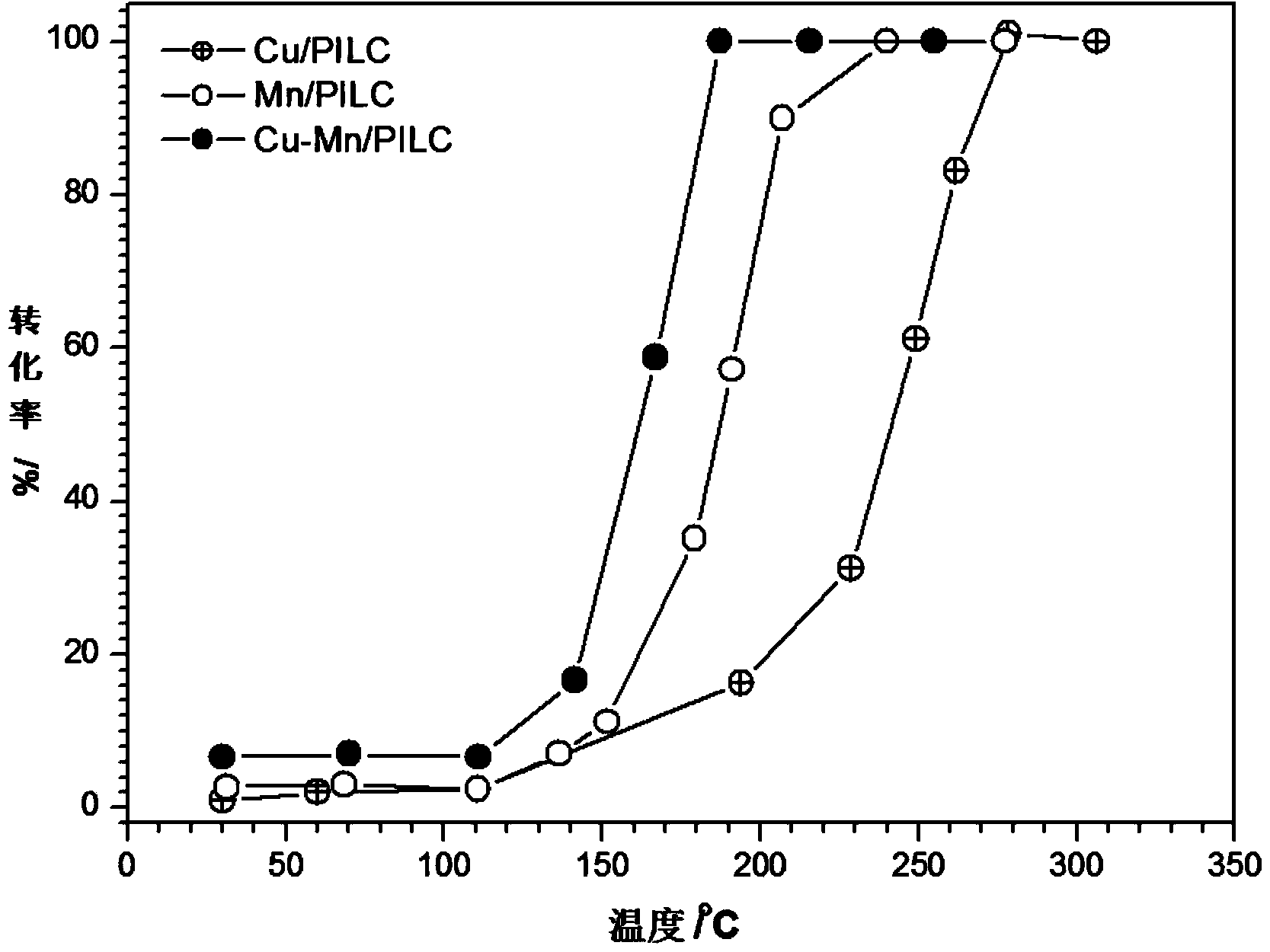

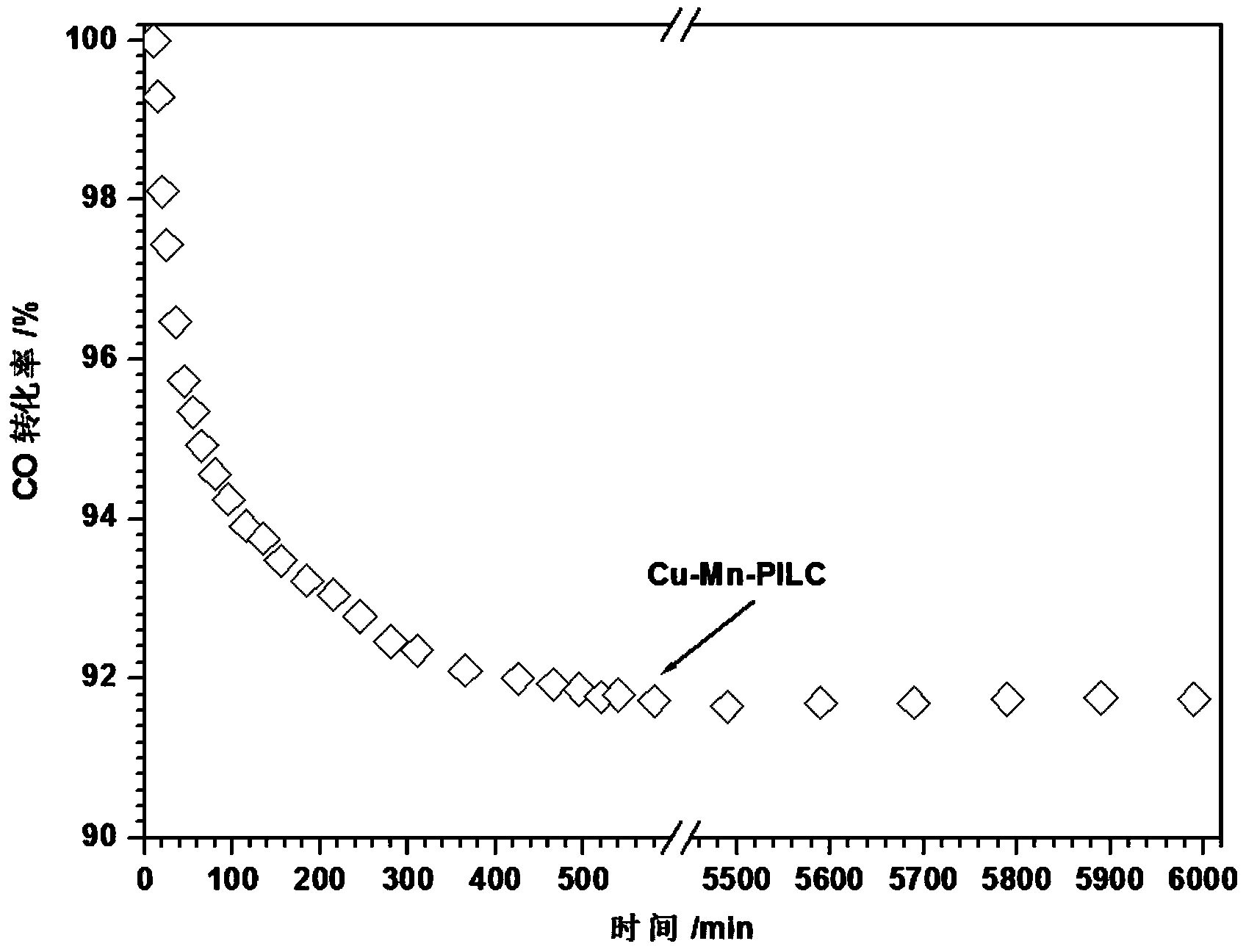

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

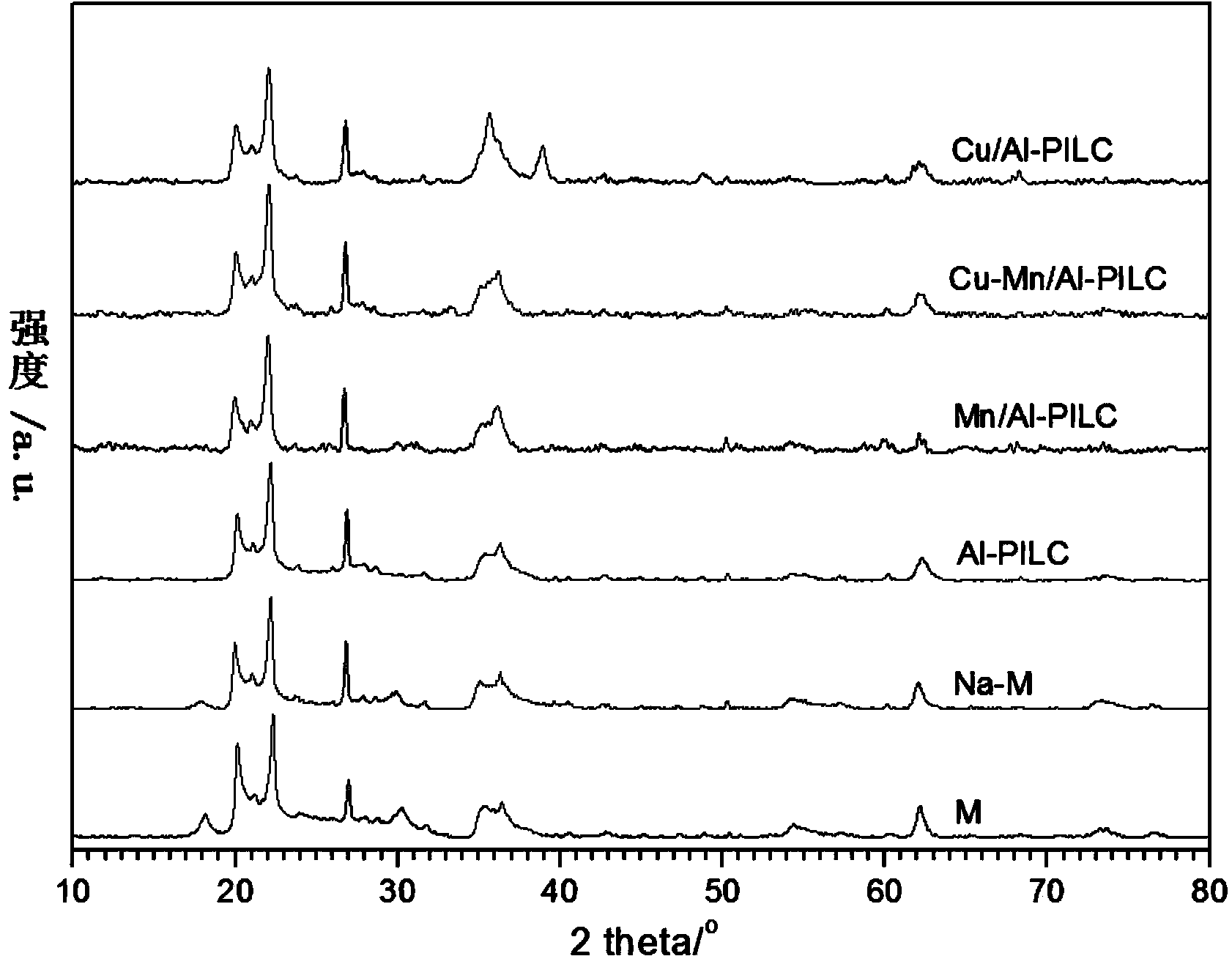

[0019] (1) Preparation of aluminum pillared montmorillonite carrier

[0020] Add the purified montmorillonite to distilled water in a certain proportion and stir to form a thick solution, water:montmorillonite (mass ratio) = 5:1, then weigh a certain proportion of NaCl and add it to the above slurry, wherein the slurry: NaCl (mass ratio) = 90:1, react at 60°C for 1 hour, then centrifuge and wash 8 times until there is no Cl - After detection, the product was dried at 120°C for 24 hours to obtain sodium montmorillonite.

[0021] At 60°C, add 0.1 mol / L AlCl to 0.1 mol / L NaOH solution at a rate of 1 ml / min 3 solution, where [Al 3+ ]: [OH - ] (molar ratio) = 1:1, keep stirring for 1 hour, and then let the solution stand at room temperature for 22 hours to obtain aluminum columning agent.

[0022] Add the above-mentioned sodium montmorillonite to distilled water according to a certain proportion, and make a suspension slurry of sodium montmorillonite according to the ratio of d...

Embodiment 2

[0027] (1) Preparation of aluminum pillared montmorillonite carrier

[0028] Add the purified montmorillonite to distilled water according to a certain proportion and stir it into a thick solution, wherein water:montmorillonite (mass ratio) = 8:1, then weigh a certain proportion of NaCl and add it to the above slurry, wherein the slurry : NaCl (mass ratio) = 95:1, react at 70°C for 2 hours, then centrifuge and wash 10 times until there is no Cl - After detection, the product was dried at 130°C for 36 hours to obtain sodium montmorillonite.

[0029] At a temperature of 70°C, add 0.2 mol / L AlCl to 0.2 mol / L NaOH solution at a rate of 1.5 ml / min 3 solution, where [Al 3+ ] / [OH - ] (molar ratio) = 2:1, keep stirring for 2 hours, and then let the solution stand at room temperature for 24 hours to obtain aluminum columning agent.

[0030]Add the above-mentioned sodium montmorillonite into distilled water according to a certain proportion, and make a suspension slurry of sodium mo...

Embodiment 3

[0035] (1) Preparation of aluminum pillared montmorillonite carrier

[0036] Add the purified montmorillonite to distilled water in a certain proportion and stir to form a thick solution, water: montmorillonite (mass ratio) = 10:1, then weigh a certain proportion of NaCl and add it to the above slurry, wherein the slurry: NaCl (mass ratio) = 100:1, react at 80°C for 3 hours, then centrifuge and wash 12 times until there is no Cl - After detection, the product was dried at 140°C for 48 hours to obtain sodium montmorillonite.

[0037] At a temperature of 80°C, add 0.1-0.3mol / L AlCl to 0.3mol / L NaOH solution at a rate of 2ml / min 3 solution, where [Al 3+ ] / [OH - ] (molar ratio) = 3, continued to stir for 3 hours, and then left the solution at room temperature for 26 hours to obtain an aluminum columnar agent.

[0038] Add the above-mentioned sodium montmorillonite to distilled water according to a certain proportion, and make a suspension slurry of sodium montmorillonite accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com