Car luggage rack arc bending machine and luggage rack machining method thereof

A technology of automobile luggage rack and luggage rack, which is applied in the field of automobile luggage rack bending system, automobile luggage rack bending machine and its processing luggage rack, which can solve the problems of cracking or breaking, poor appearance quality, high scrap rate, etc., and achieve zero Scratch marks, good product surface quality, and improved processing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

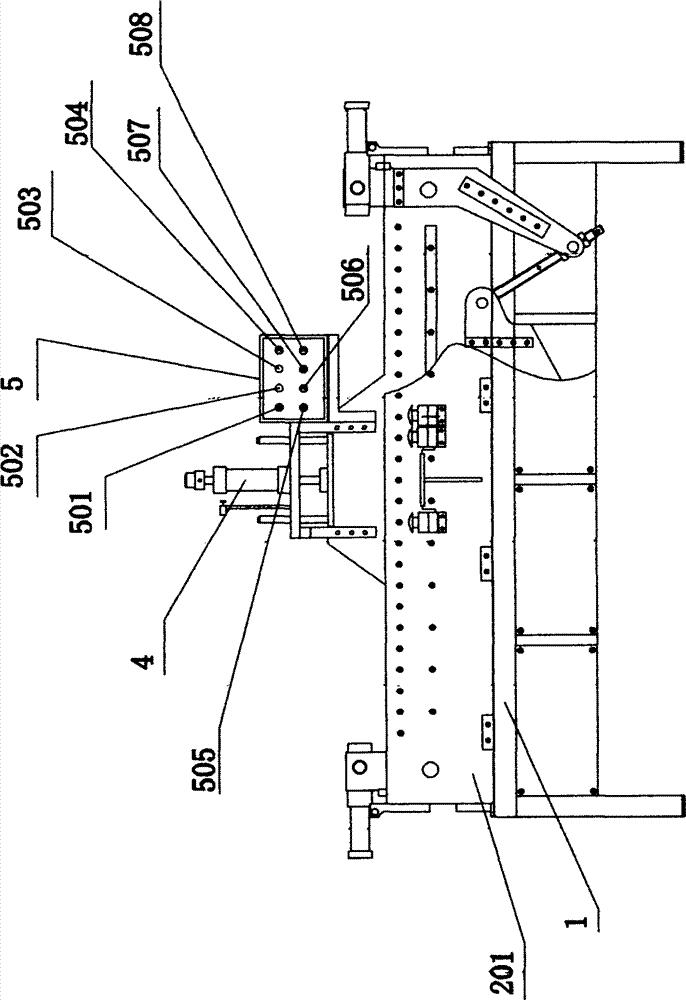

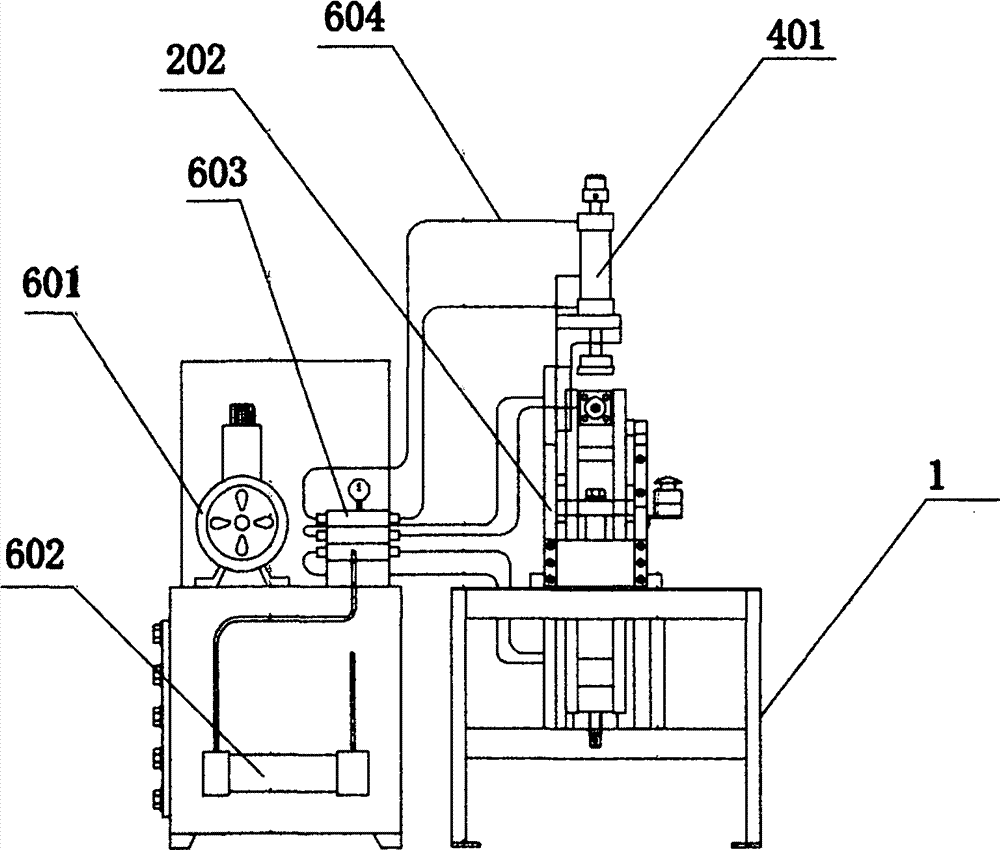

[0046] Such as Figure 1 to Figure 6 As shown, the car roof rack arc bending machine includes a frame 1, the rack 1 is set horizontally, the model of the car roof rack 7 is XLY1070, and the technical parameters of the product model: length 1070 (mm), left arc It is R549.85 (mm), the right arc is R631.05 (mm), and the height is 86 (mm).

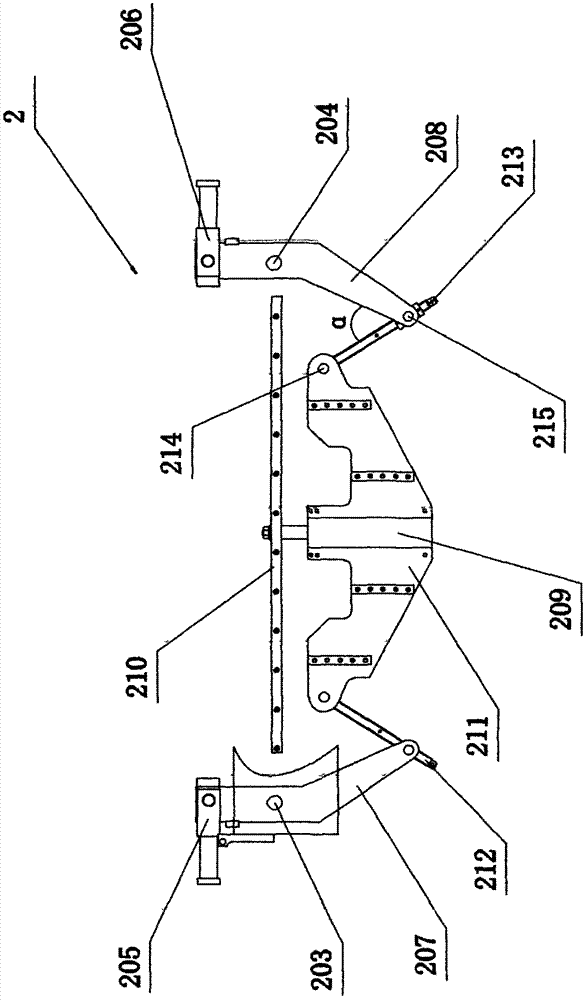

[0047] The car roof rack arc bending machine also includes a main body 2, a mold assembly 3, a machine head assembly 4, and an electrical control component 5. The main body 2 includes a front wall panel 201, a rear wall panel 202, a left rotation shaft 203, and a right rotation shaft 204 , Left core cylinder 205, right core cylinder 206, left swing arm 207, right swing arm 208, bending cylinder 209, fixed plate 210, swing block 211, left work piece curvature adjustment component 212, right work piece curvature adjustment component 213;

[0048] The front wall panel 201 and the rear wall panel 202 are respectively fixedly arranged above the front a...

Embodiment 2

[0066] Such as Figure 1 to Figure 6 As shown, the car roof rack arc bending machine includes a frame 1, the rack 1 is set horizontally, the model of the car roof rack 7 is XLY1590, and the technical parameters of the product model: length 1590 (mm), left arc It is R649.95, the right arc is R651.75 (mm), and the height is 135 (mm).

[0067] The technical parameters of the mold assembly 3: the bottom mold length L is 1850 (mm), the total height h is 180 (mm), the total width s is 120 (mm), and the upper plate length 1 is 750 (mm).

[0068] When different types of car luggage racks 7 are processed by the same car luggage rack bending machine, they can be adjusted between the left swing arm 207, right swing arm 208 and the left workpiece camber adjusting part 212 and right workpiece camber adjusting part 213 respectively. The included angle α, the working setting time of the left leading cylinder 205 and the right leading cylinder 206, and the setting time of bending and stretching a...

Embodiment 3

[0071] Such as Figure 1 to Figure 6 As shown, the car luggage rack arc bending machine includes a frame 1, the rack 1 is set horizontally, the model of the car luggage rack 7 is XLY1980, and the technical parameters of the product model: length 1980 (mm), left arc It is R1530.25, the right arc is R1671.35 (mm), and the height is 160 (mm).

[0072] The technical parameters of the mold assembly 3: the bottom mold length L is 2170 (mm), the total height h is 260 (mm), the total width s is 130 (mm), and the upper plate length 1 is 1600 (mm).

[0073] When different types of car luggage racks 7 are processed by the same car luggage rack bending machine, they can be adjusted between the left swing arm 207, right swing arm 208 and the left workpiece camber adjusting part 212 and right workpiece camber adjusting part 213 respectively. The included angle α, the left core cylinder 205, the right core cylinder 206 work setting time and the bending and stretching setting time are realized, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com