Bamboo-based flat pallet used for logistics operation and production method thereof

A flat tray, bamboo technology, applied in the field of bamboo flat tray and its production, can solve the problems of easy rust, insufficient strength, consumption, etc., and achieve the effects of relieving logistics pressure, good mechanical properties, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] Bamboo flat tray for logistics operations of the present invention, its preferred embodiment is:

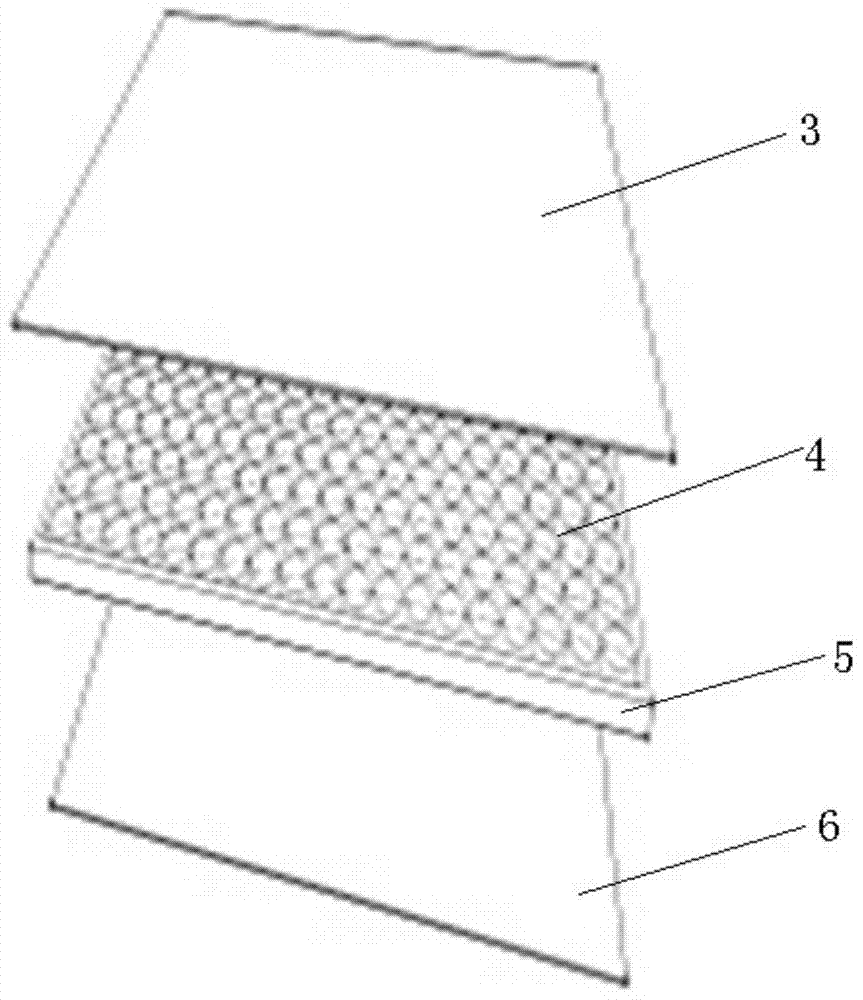

[0018] It includes a supporting board, the lower surface of the supporting board is provided with pads, the supporting board includes an upper cover and a lower cover made of bamboo plywood, and a plurality of supports are arranged between the upper cover and the lower cover For the bamboo ring, an edge banding strip is provided between the edges of the upper cover plate and the lower cover plate.

[0019] The plurality of supporting bamboo rings fills the cavities closed by the edge banding.

[0020] The edge banding strips are made of bamboo plywood or plastic strips.

[0021] The thickness of the bamboo plywood is 2mm, the average diameter of the supporting bamboo ring is 30mm, and the height is 26mm, and the thickness of the edge banding is 10mm, and the width is 25mm.

[0022] The above-mentioned manufacturing method of the bamboo flat tray for logistics operations ...

specific Embodiment

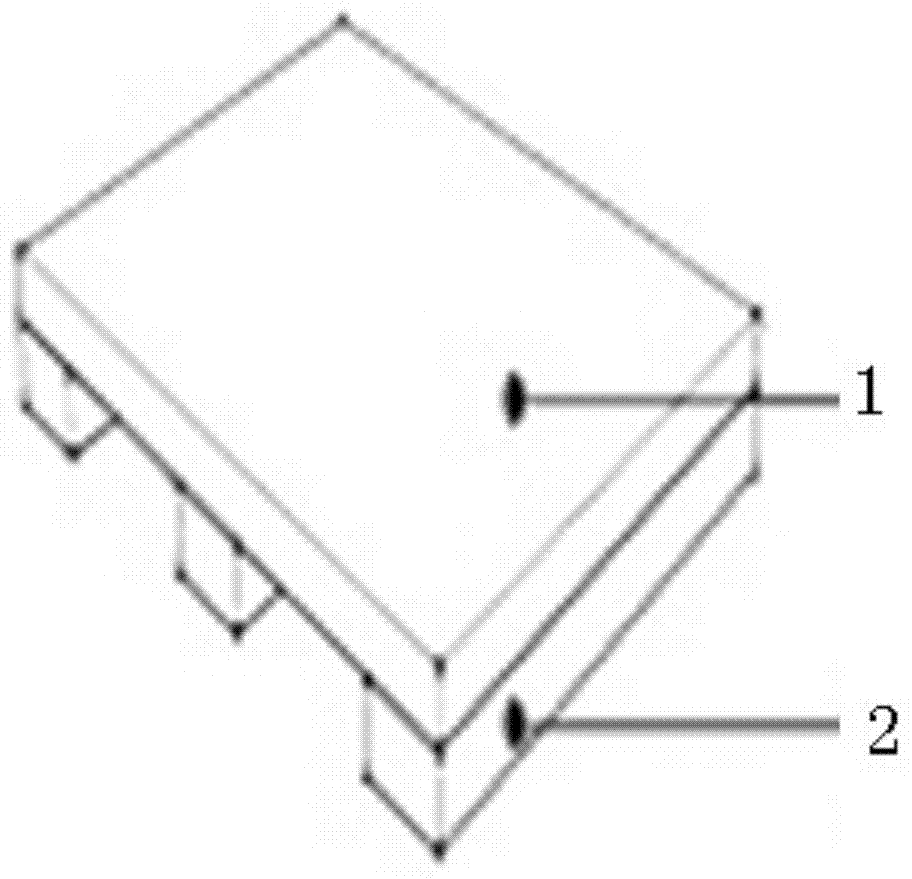

[0033] Such as figure 1 , figure 2 As shown, the bamboo plywood of the corresponding size is cut according to the specific required pallet size.

[0034] Cut common Moso bamboos (30mm in diameter on average) in the market into bamboo rings with a height of 26mm, put the bamboo rings in a metal basket, put them into a steamer and boil them for 45-60 minutes at a water temperature of 100°C±5, take them out Send it to dry in the drying room, dry to the moisture content of the bamboo ring is X-10% and take out.

[0035] Glue the cut bamboo plywood on one side.

[0036] Put the rubber side of the bamboo plywood on the operating table, the bamboo ring is combined on the bamboo board to form a honeycomb structure, the thickness of the bamboo plywood is 10mm, and the width of the bamboo plywood is 25mm. face down.

[0037] Put the prepared planks into the hot press, the temperature of the hot press is controlled at 120°C±5, and the pressing time is 7 minutes under the pressure of...

Embodiment 2

[0039] Cut the wooden strips with a height of 90mm and a width of 90mm and the same length as the width of the pallet as spacers and bind them together with the finished boards to make such figure 1 tray shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com