A barreled water liner and its filling process

A barreled water and liner technology, which is applied in barrel/cask filling, packaging, liquid filling, etc., can solve the problems of unsuitable and complicated filling process, reduce the cleaning process of buckets, reduce requirements, and save filling The effect of loading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

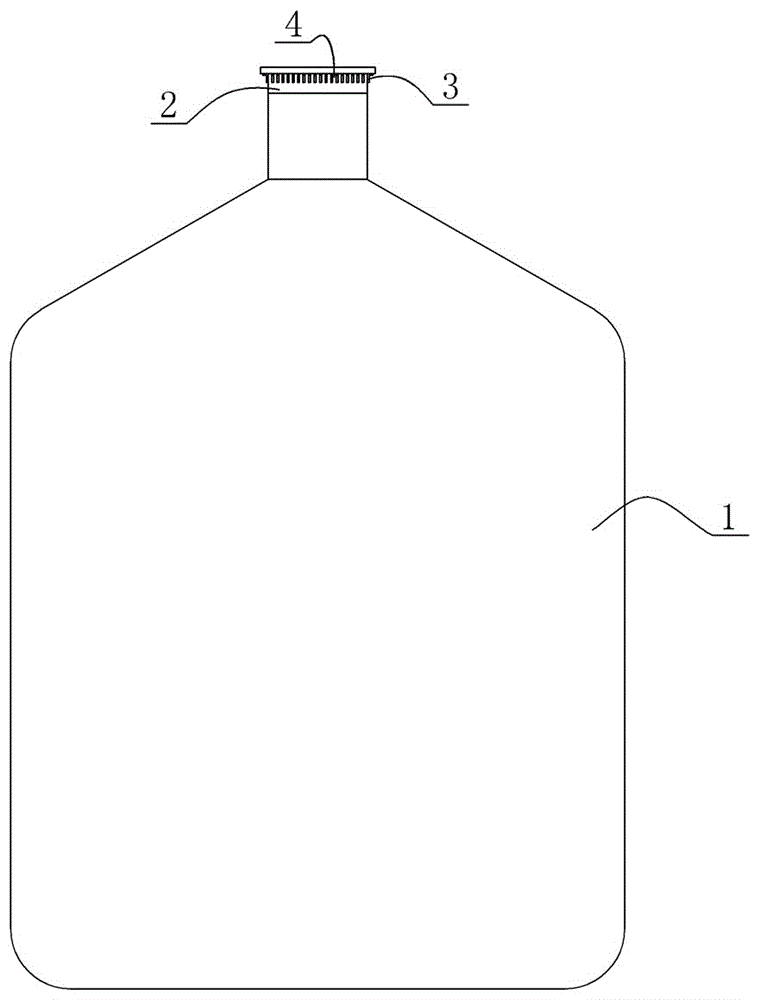

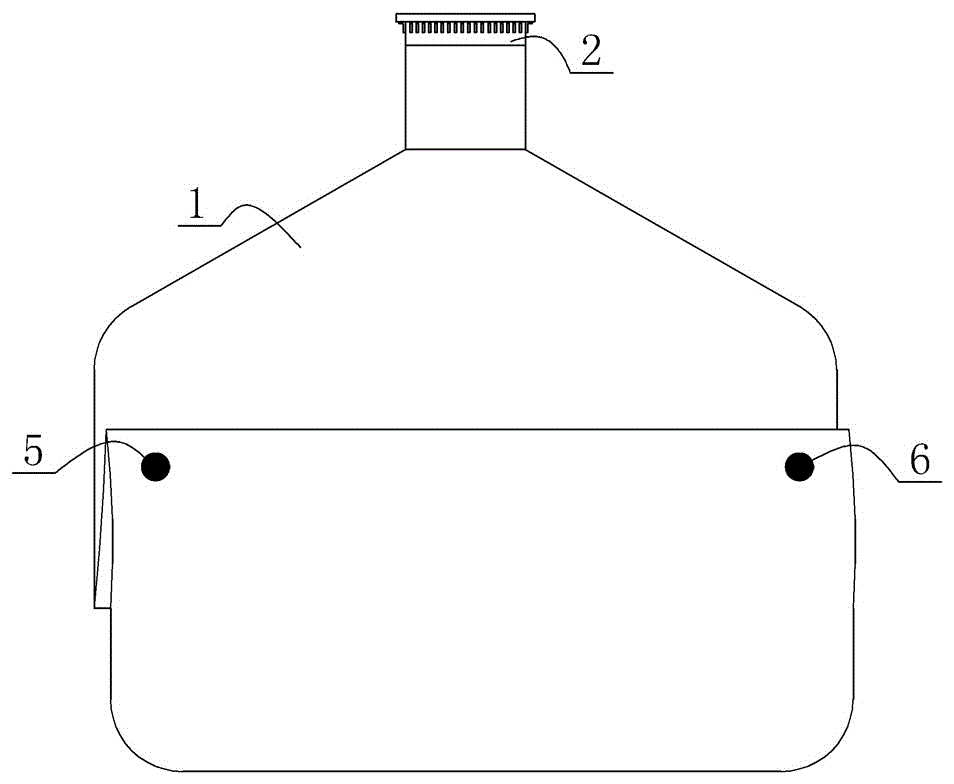

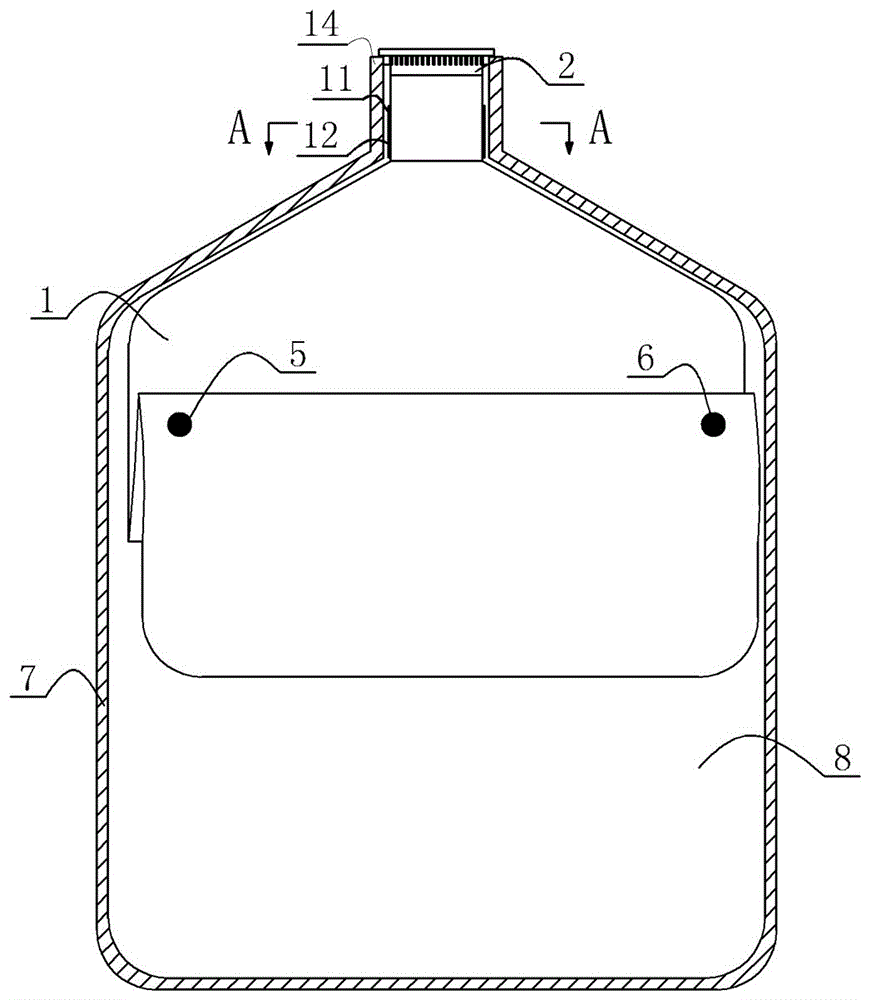

[0025] like figure 2 As shown, the structural representation of the barreled water liner of the present invention is provided, which includes an inner liner body 1 and an annular sleeve 2, and the shape and size of the inner liner body 1 should be consistent with the inner cavity of the bucket 7, so that After storing the drinking water 10 in the inner tank body 1, it is completely pasted on the inner wall of the bucket 7. The middle part of the inner tank body 1 is folded together in multiple layers, and the folds are fixed by the left fixed point 5 and the right fixed point 6; the left fixed point 5 and the right fixed point 6 are only temporarily fixed to the inner tank body 1, when the inner tank body After the left fixed point 5 and the right fixed point 6 fall off, the inner tank body 1 will not be damaged, and the sealing performance of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com