Oriented quantitative arc support roller

A kind of idler and arc technology, applied in the field of directional quantitative arc idler, can solve the problems such as the inability to intuitively indicate the wear degree of the idler, the wear of the idler not being replaced in time, and the friction on the surface of the multi-roller, so as to reduce the tearing Risk of belts, guaranteed service life, effect of improving impact resistance and load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

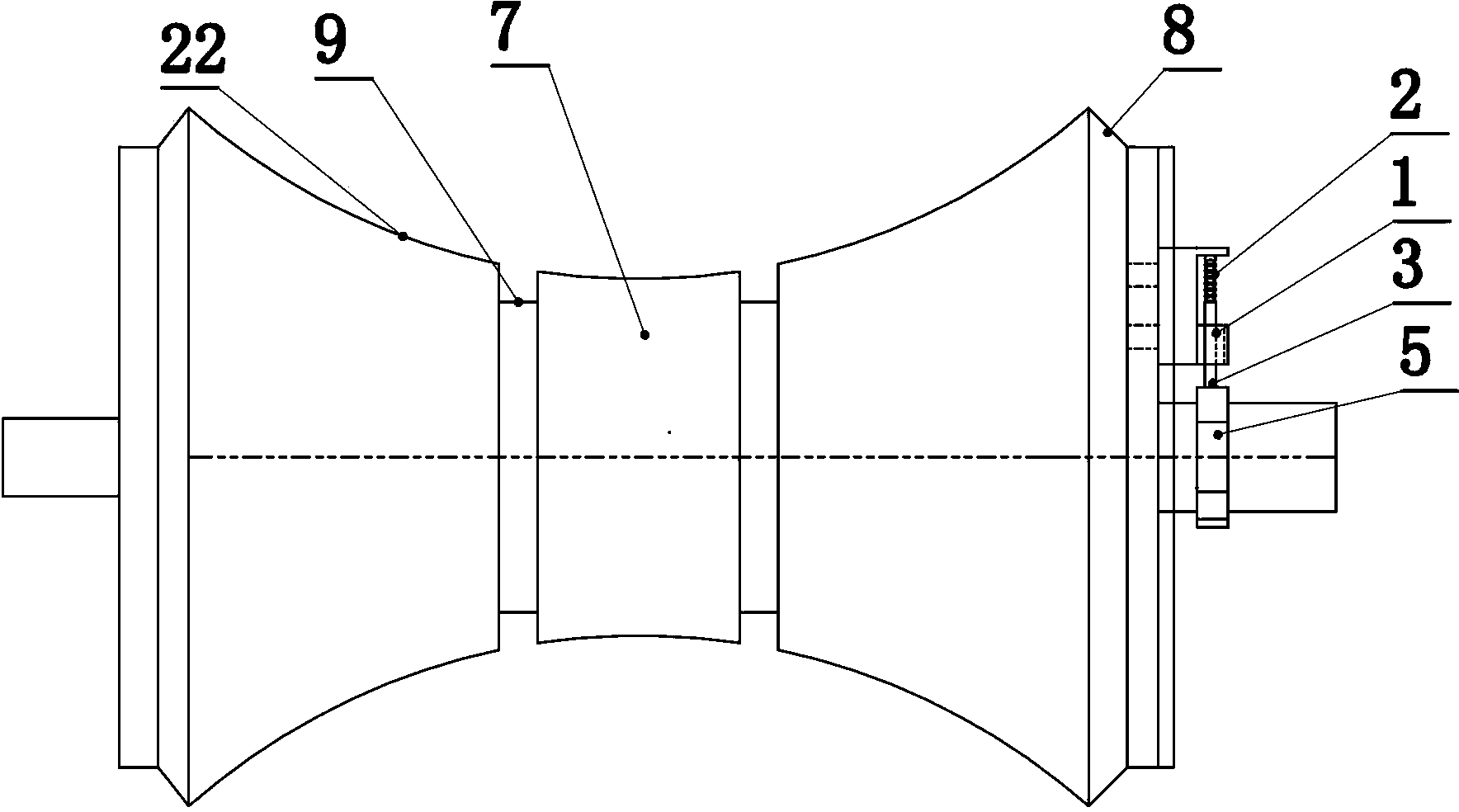

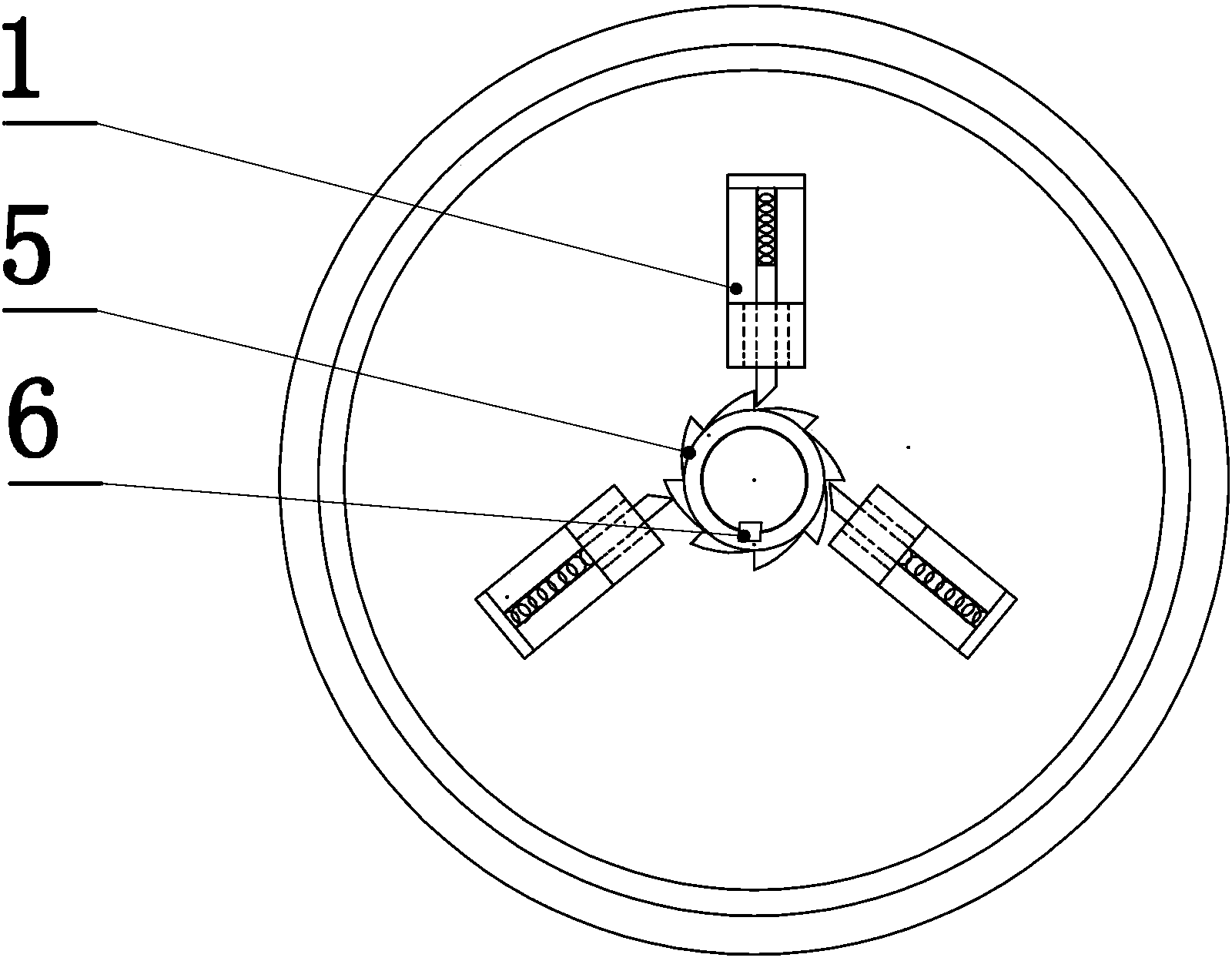

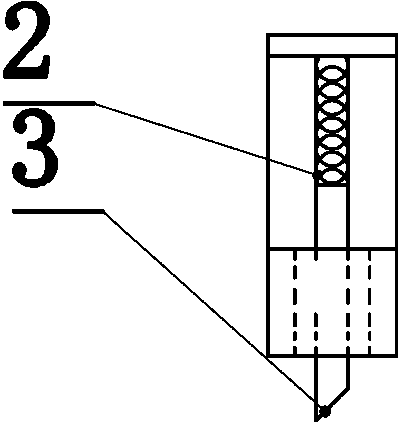

[0029] The assembly process of the curved idler roller: put the C-type card 17 into the card slot 19 on the shaft 18, put the outer bearing chamber 15, bearing 16, wear-resistant sleeve 13, and sealing ring 14 in sequence, and put the sealing retainer The ring 23 is pressed into the cylinder 7 . Such as Figure 7 As shown, the sealing assembly 11 and the bearing 16 on the other side of the cylinder body 7 are installed. After assembling, the sealing ring 14 and the wear-resistant sleeve 13 perform contact friction sealing, and the tapered card 20 is pressed on the tapered bayonet 21 on the sealing ring 14 to rotate together with the sealing ring 14, and the sealing retaining ring 23 on the side is The shaft 18 can be sealed to keep large particles of dust out. When multiple directional and quantitative arc-shaped rollers are used together, a complete arc needs to be formed according to the size of the arc, which can fit the belt well. The anti-reverse device 1 of the idler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com