Flocculation-precipitation integrated reactor for water treatment

An integrated, reactor technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of unsuitable water supply in rural and remote areas and unsuitable for construction Problems such as waterworks and the construction of large structures are not suitable, so as to save costs, reduce floor space, and reduce turbidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

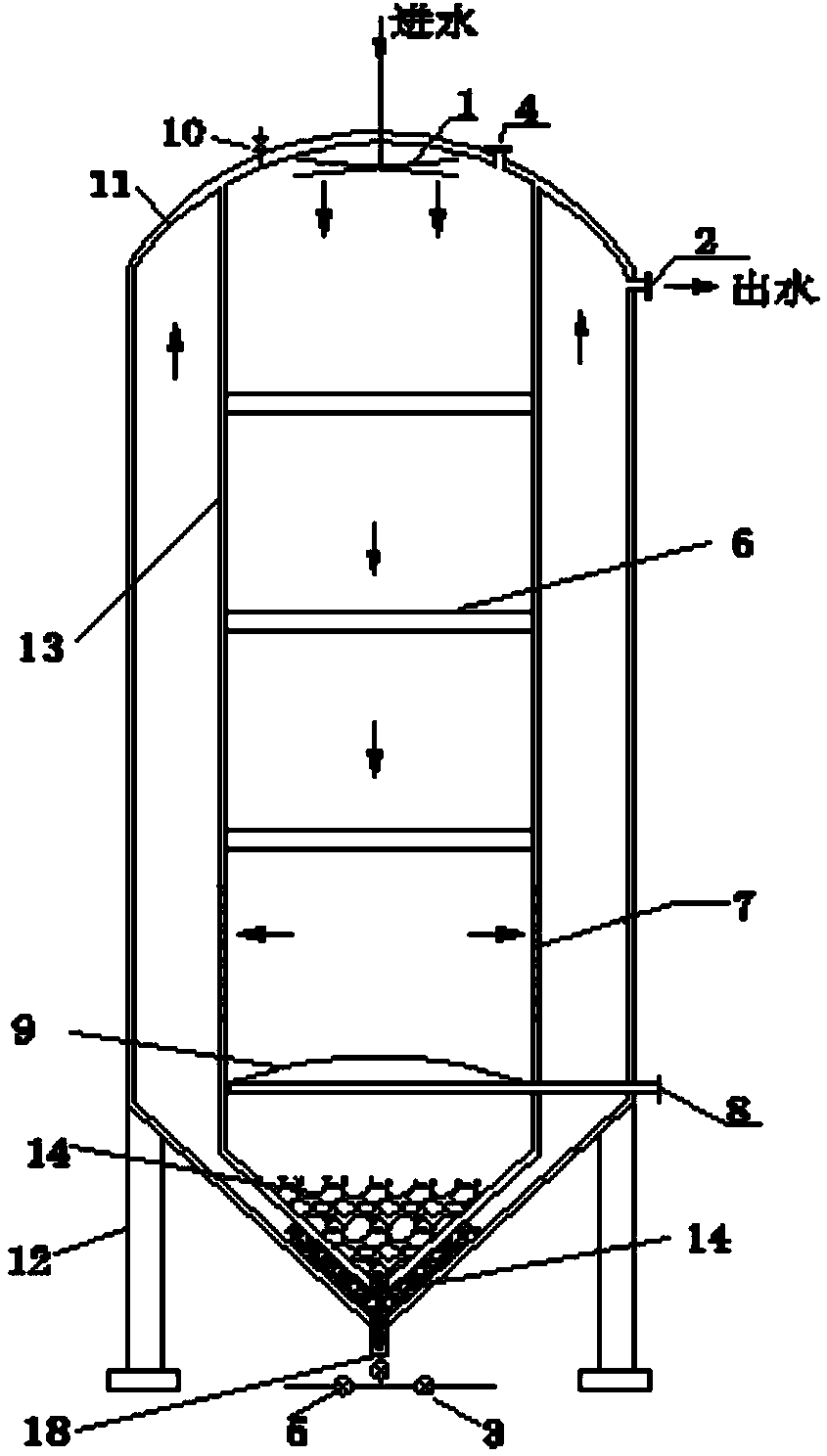

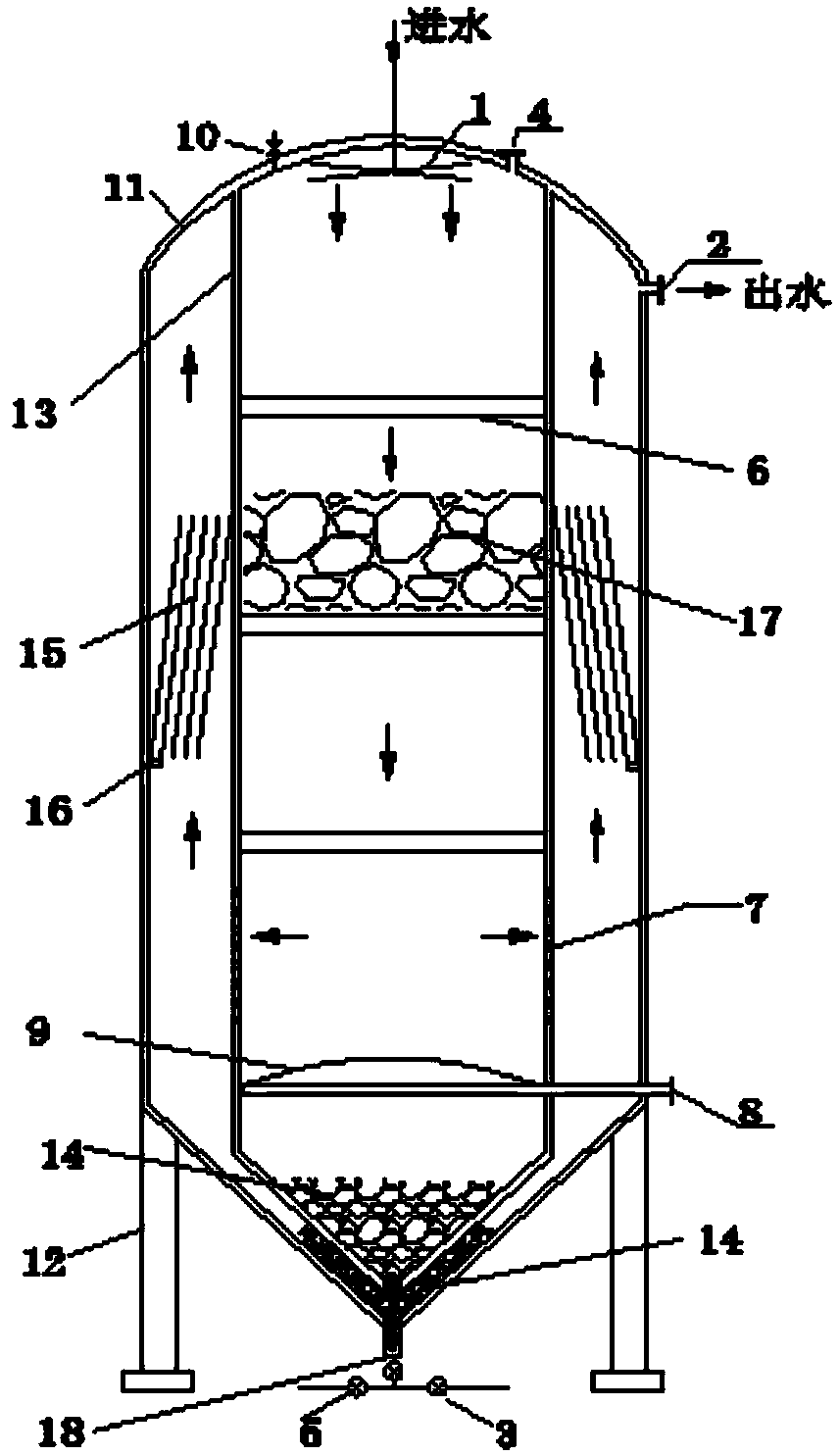

[0013] The flocculation-sedimentation integrated reactor for water treatment proposed by the present invention has a structure such as figure 1 As shown, it includes: an outer cylinder 11, an inner cylinder 13, a water distributor 1, a plurality of perforated plates 6 and an aeration head 9. The bottom of the outer cylinder 11 is funnel-shaped, and a sediment outlet 18 is opened at the bottom of the funnel-shaped outer cylinder. The outer cylinder 13 is supported by the legs 12, and the upper wall of the outer cylinder 11 is provided with the water outlet 2 of the integrated reactor. The inner cylinder 13 is placed in the outer cylinder 11, the top of the inner cylinder 13 is fixed on the cylinder cover of the outer cylinder 11, the water distributor 1 is placed on the upper part of the inner cylinder 13, the water distributor 1 is connected with the water inlet at the top of the inner cylinder, and the inner A pressure regulating valve 10 is installed on the cylinder cover at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com